Double-layer polystyrene curing bin

A polystyrene, curing technology, applied in the field of EPS extruded board production equipment, can solve the problems of easy flying of materials, expansion stress, difficulty in controlling curing time, and difference in material curing time, so as to facilitate curing and prevent materials from flying The effect of flying and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

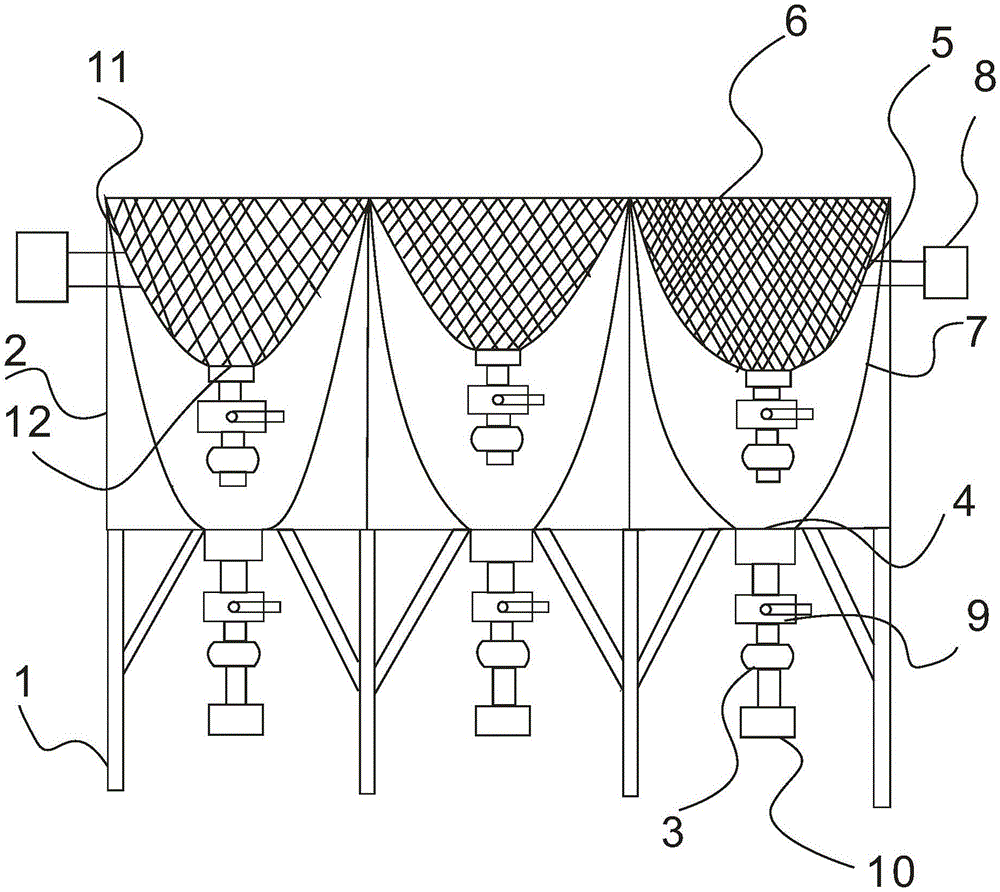

[0011] As shown in the figure, a double-layer polystyrene curing bin includes a support frame 1 and a bin body arranged above the support frame 1. There are multiple bin bodies arranged side by side, and each bin body 1 includes a bin body frame. 2 and the internal ventilating mesh and top ventilating mesh 6 mounted on the warehouse frame 2, the interior ventilating mesh of each warehouse body is divided into upper and lower layers, and the upper interior ventilating mesh 11 top of the upper layer is provided with a feeding port 5 , the feed inlet 5 is connected to the feed inlet induced draft fan 8, the upper layer discharge port 12 is provided at the bottom of the upper internal ventilation net 11, and the upper layer d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com