Hydraulic piling system and cartridge valve thereof

A cartridge valve and hydraulic technology, applied in the direction of fluid pressure actuators, sheet pile walls, servo motor components, etc., can solve the problems of slow control response speed, increased oil circuit complexity, high strike frequency, etc., to achieve guaranteed action Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

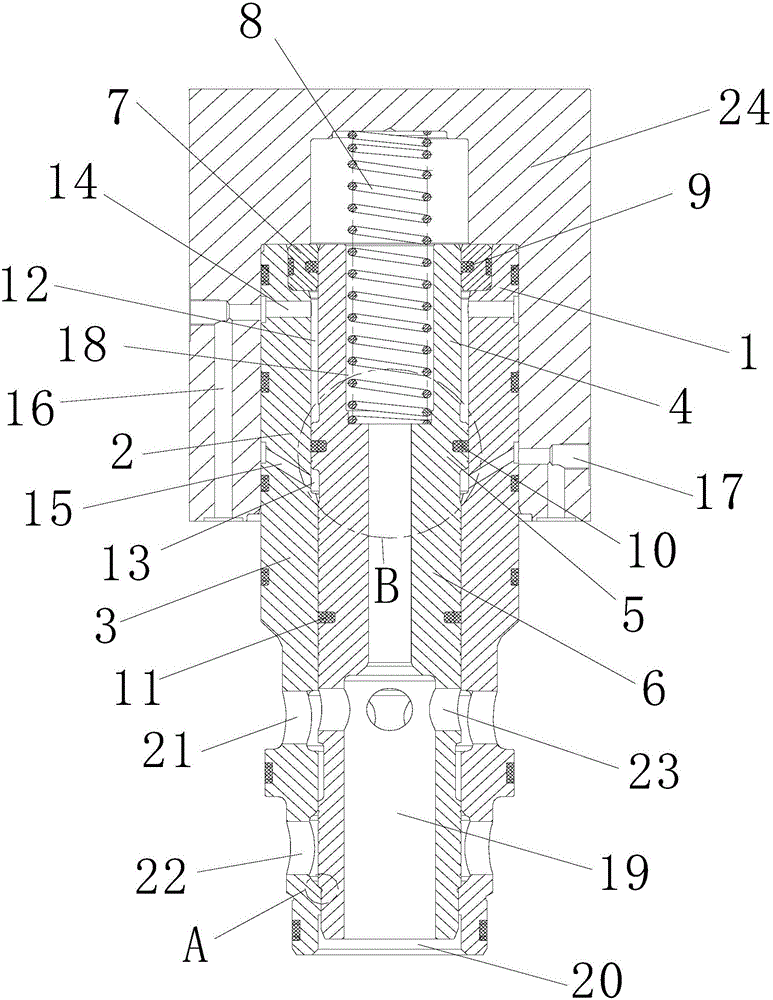

[0032] The present invention will be further described in detail in conjunction with the accompanying drawings and specific embodiments.

[0033] For the convenience of description, the up, down, left, and right directions mentioned below are the same as figure 1 The up, down, left, and right directions are the same.

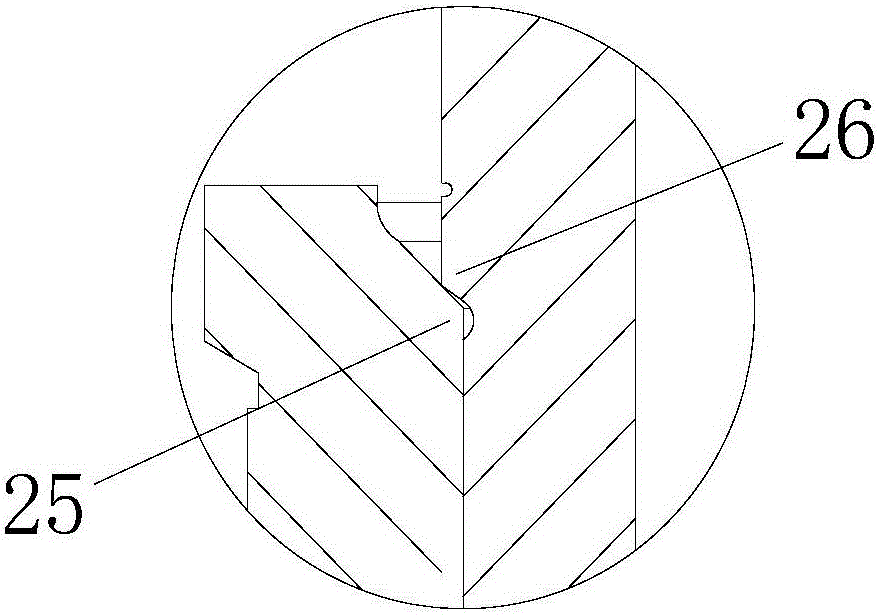

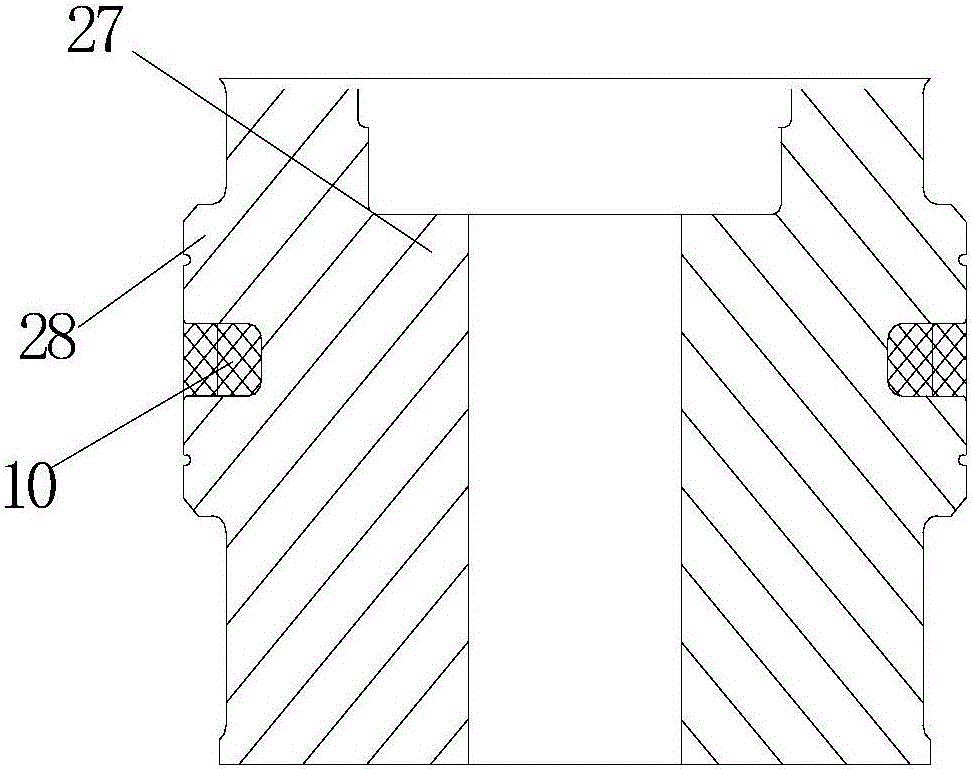

[0034] combine figure 1 and Figure 4 As shown, a cartridge valve for a hydraulic piling system includes a control cover plate, a valve core, a valve sleeve, a return spring, and a valve core guide sleeve. The spool is divided into the first spool, the second spool and the third spool from top to bottom, and the valve sleeve is divided into the first spool, the second spool from top to bottom. Section valve sleeve, third section valve sleeve. The valve sleeve is provided with an axial through hole, and the axial through hole penetrates from the lower end of the valve sleeve to the upper end of the valve sleeve. Above the end surface is the first section of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com