laminated film

A technology of laminated film and surface layer, applied in the direction of coatings, layered products, synthetic resin layered products, etc., can solve the problems of surface damage and surface layer peeling of molding materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0297] Next, the present invention will be described based on examples, but the present invention is not limited to these examples.

[0298] [urethane (meth)acrylate A]

[0299] [Synthesis of urethane (meth)acrylate A1]

[0300] 50 parts by mass of toluene, 50 parts by mass of an isocyanurate-modified type of 1,6-hexamethylene diisocyanate ("Takenet" (registered trademark) D-170N manufactured by Mitsui Chemicals, Ltd.), 76 parts by mass of polycaprolactone Modified hydroxyethyl acrylate ("Praccel" (registered trademark) FA5 manufactured by Daicel Chemical Industry Co., Ltd.), 0.02 parts by mass of dibutyltin laurate, and 0.02 parts by mass of hydroquinone monomethyl ether were mixed, and kept at 70° C. for 5 Hour. Then, 79 mass parts of toluene were added, and the toluene solution of the urethane (meth)acrylate A1 of 50 mass % of solid content concentration was obtained.

[0301] [Synthesis of urethane (meth)acrylate A2]

[0302] 50 parts by mass of toluene, 67 parts by ma...

PUM

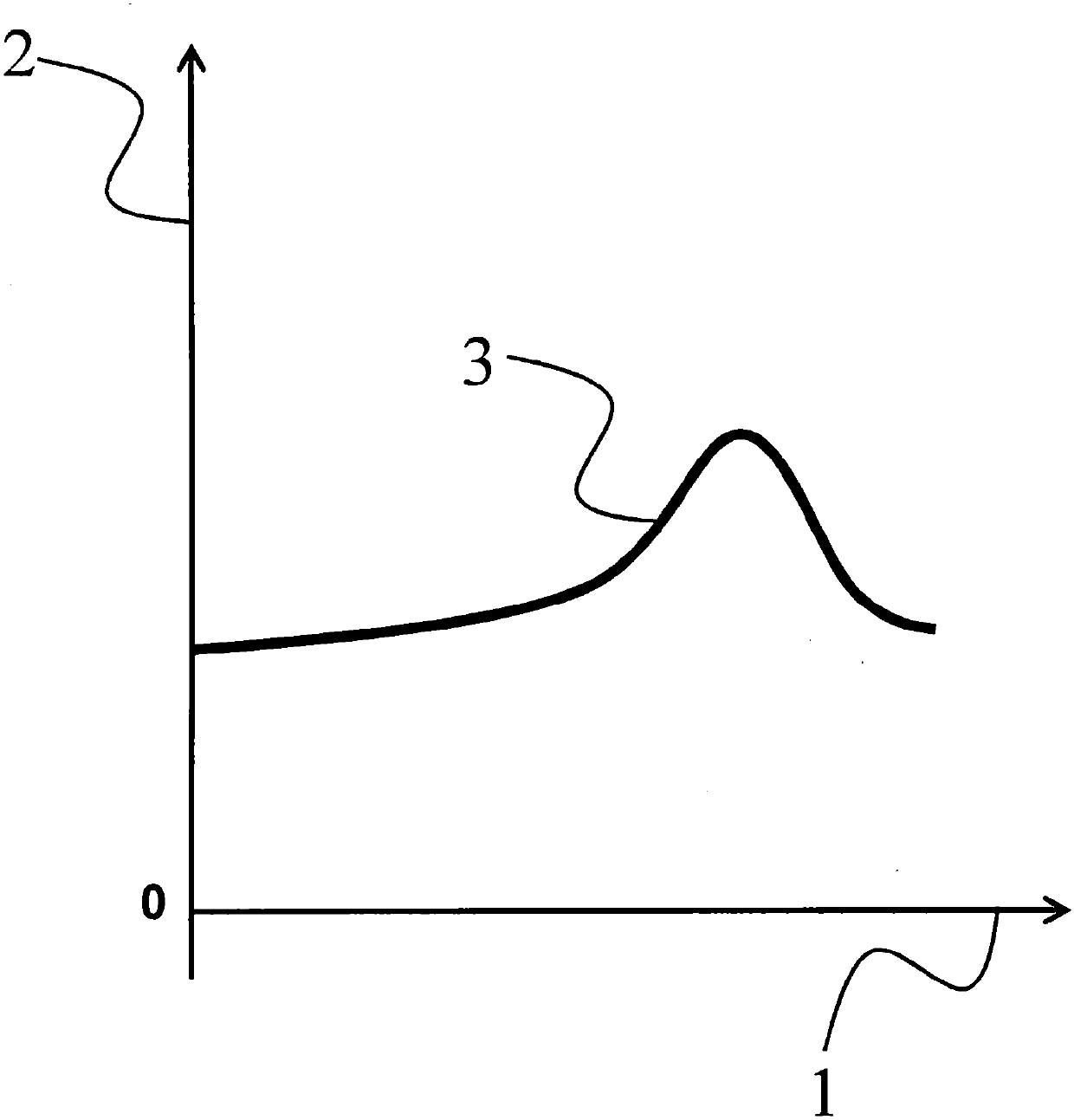

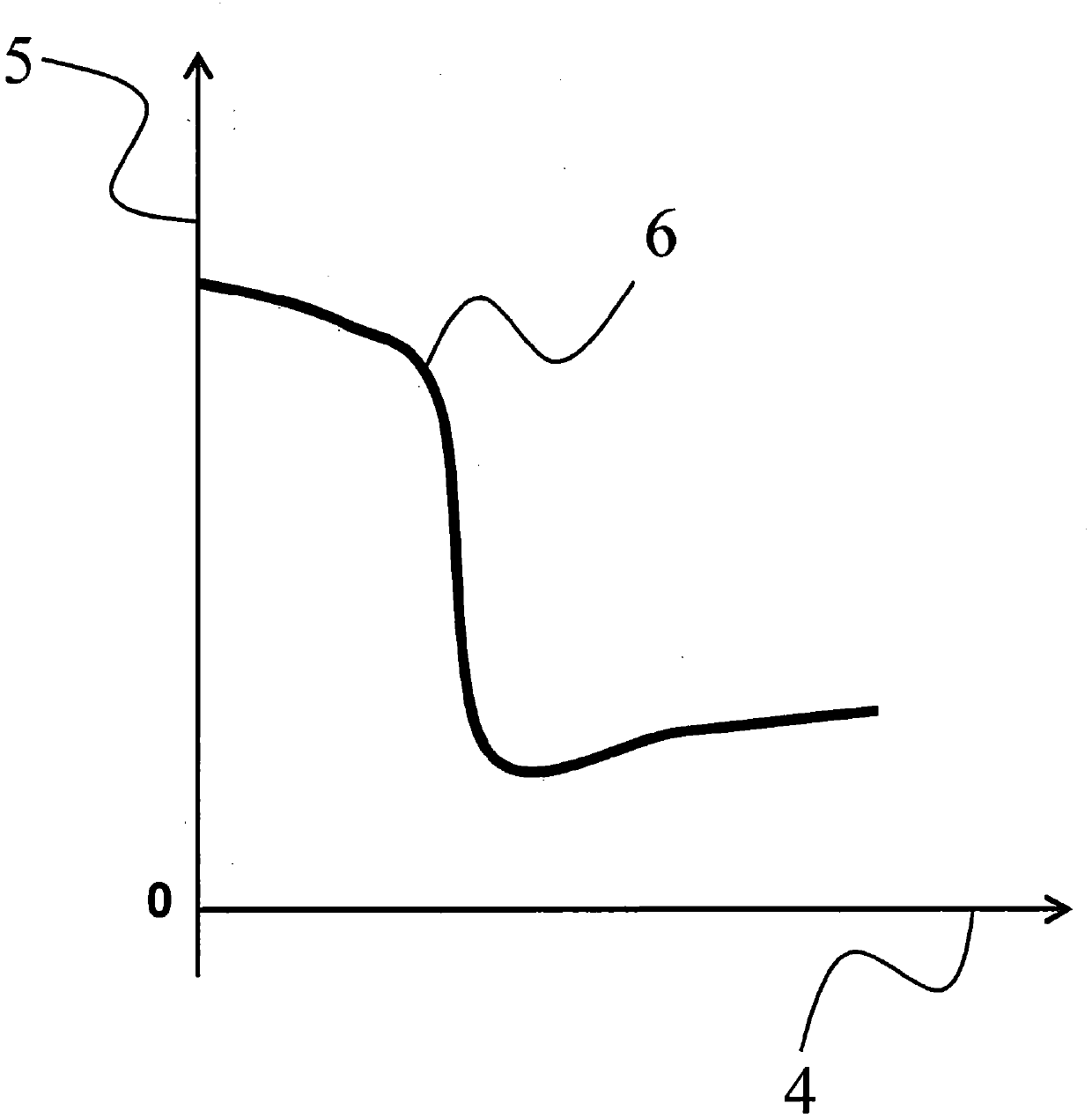

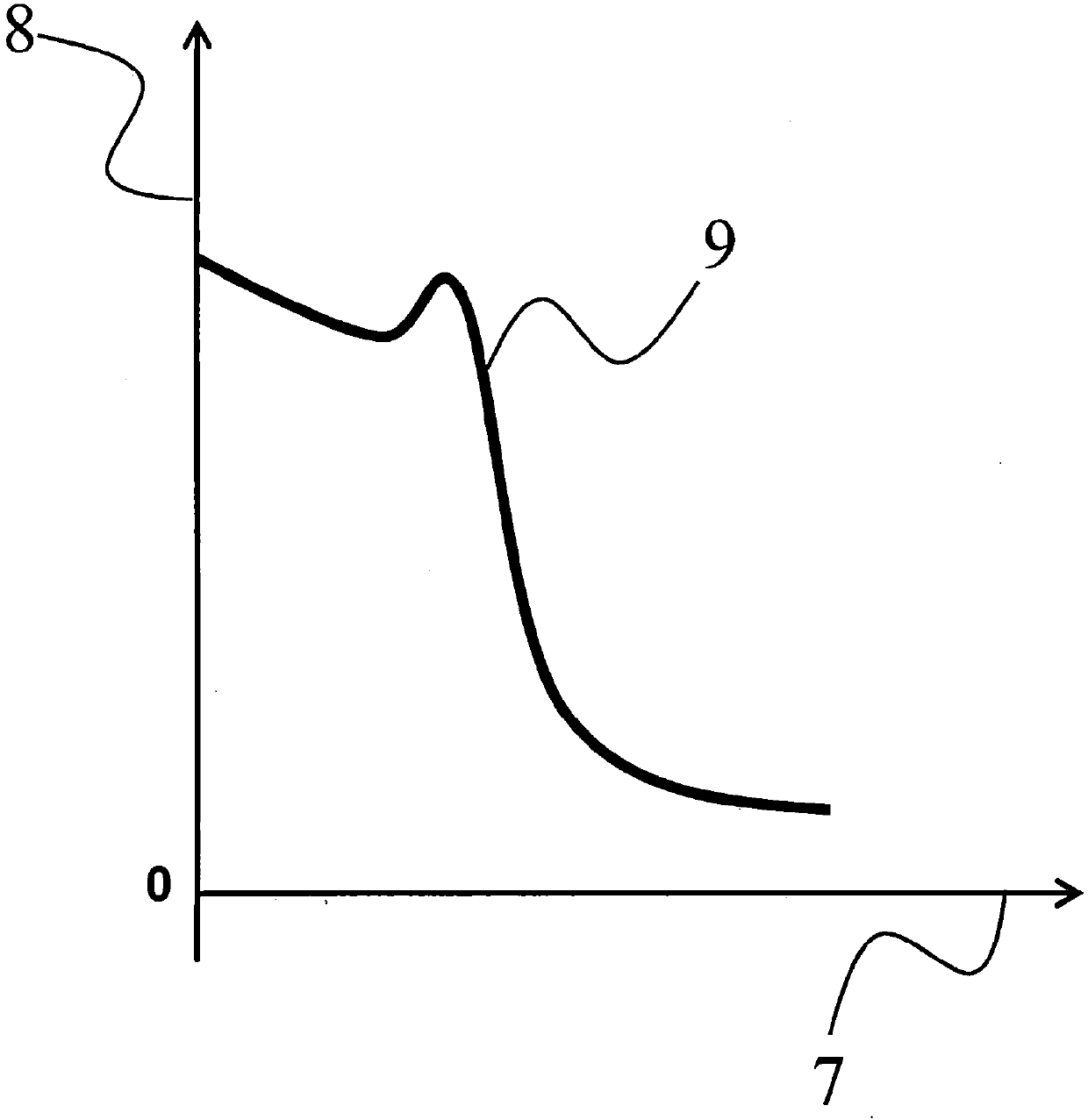

| Property | Measurement | Unit |

|---|---|---|

| storage modulus | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com