Automatic tying machine for tying crabs and method thereof

An automatic, crab-based technology, which is applied to the parts, packaging, and strapping materials of strapping machines, can solve the problems of unsuitable crabs, etc., and achieve the effects of beautiful knots, low production and maintenance costs, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

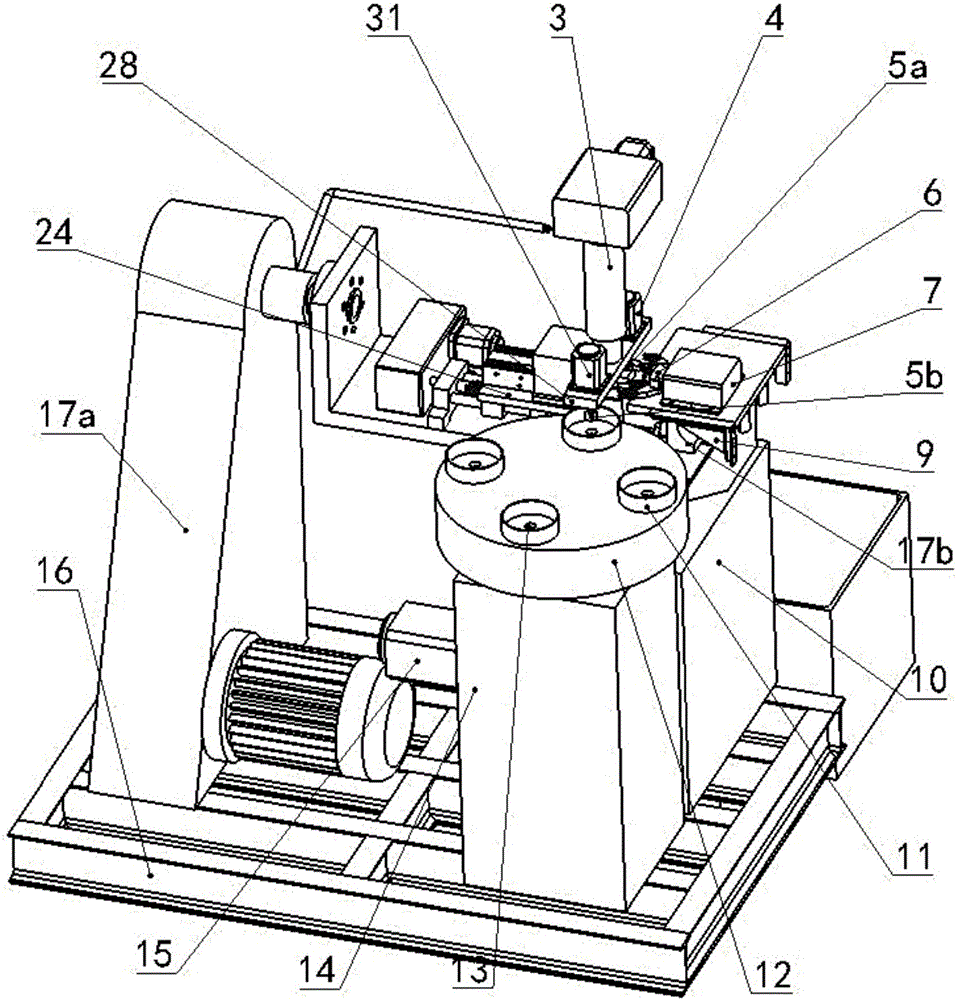

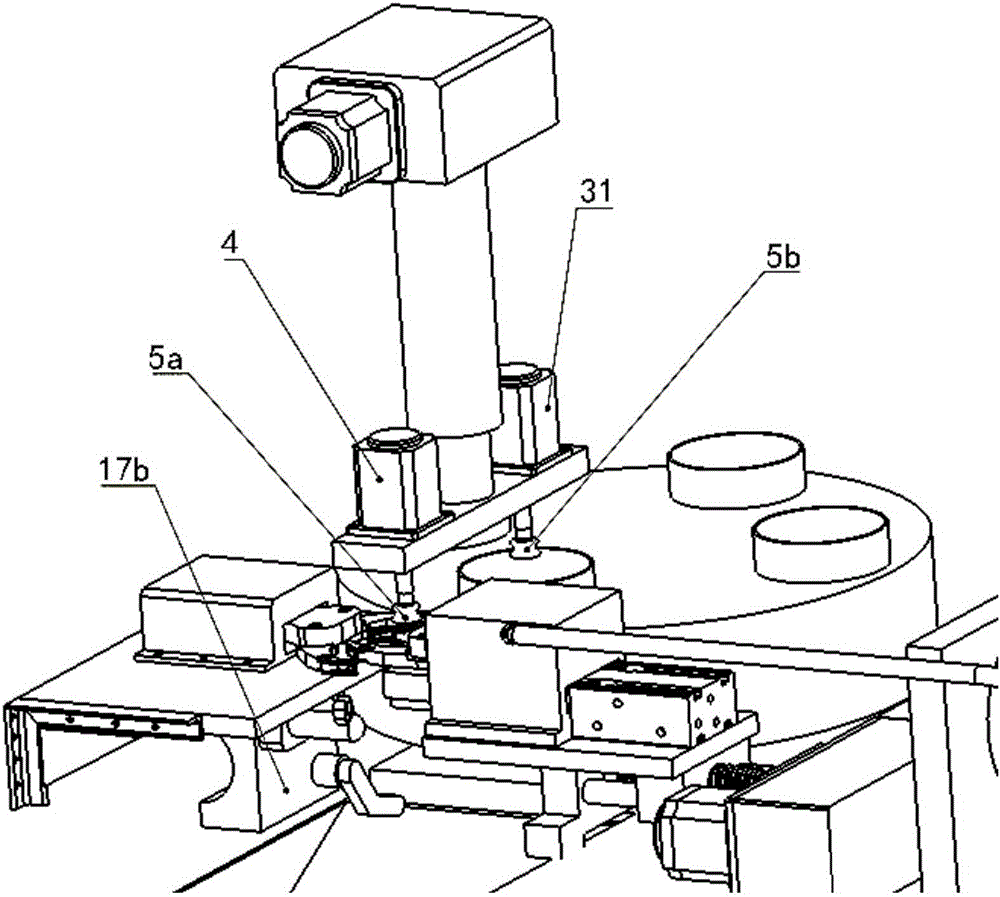

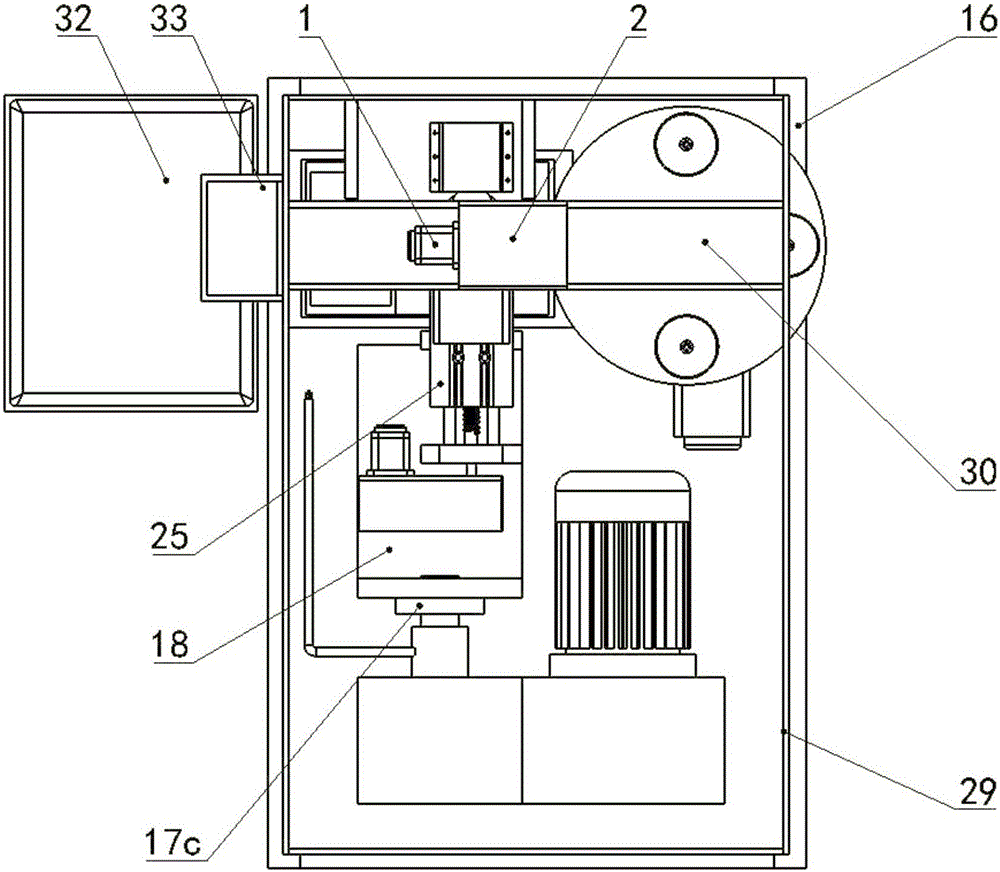

[0034] Such as figure 1 , 2, 3, 4 and 5, the automatic binding crab binding machine includes a cylinder rotating servo motor 1, a suction cup grabbing device gearbox 2, a rotating cylinder 3, a grabbing sucker servo motor 4, a grabbing sucker vacuum controller 31, a first Grab suction cup 5a, second grab suction cup 5b, suction cup mounting arm 28, fixed jaw caliper 6, fixed jaw main body 7, jaw tray 8, bracket 9, bucket collector 10, limiting disc 11, rotating disc 12 , fixed suction cup 13, rotating disk base 14, rotating disk motor 15, installation base frame 16, finishing machine base 17a, finishing machine knotter 17b, finishing machine installation disk 17c, finishing machine lead curved bar 17d, telescopic claw Tray 18, telescopic jaw gearbox 19, ball screw support 20, screw servo motor 21, ball screw shaft 22, ball screw nut 23, telescopic jaw mounting plate 24, telescopic jaw caliper 34, telescopic jaw Main body 26, telescopic tray driver 25, telescopic tray 27, cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com