Warehousing robot capable of automatically making tour for inspecting, cleaning and checking inventories

A robot and material technology, applied in the field of warehousing robots, can solve the problems of heavy workload, cumbersome and time-consuming, and achieve the effect of improving work efficiency and convenient warehouse management.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings: It should be emphasized that the embodiments of the present invention are illustrative rather than restrictive, so the present invention is not limited to the implementation described in the specific embodiments. For example, all other implementations obtained by those skilled in the art according to the technical solution of the present invention also belong to the protection scope of the present invention.

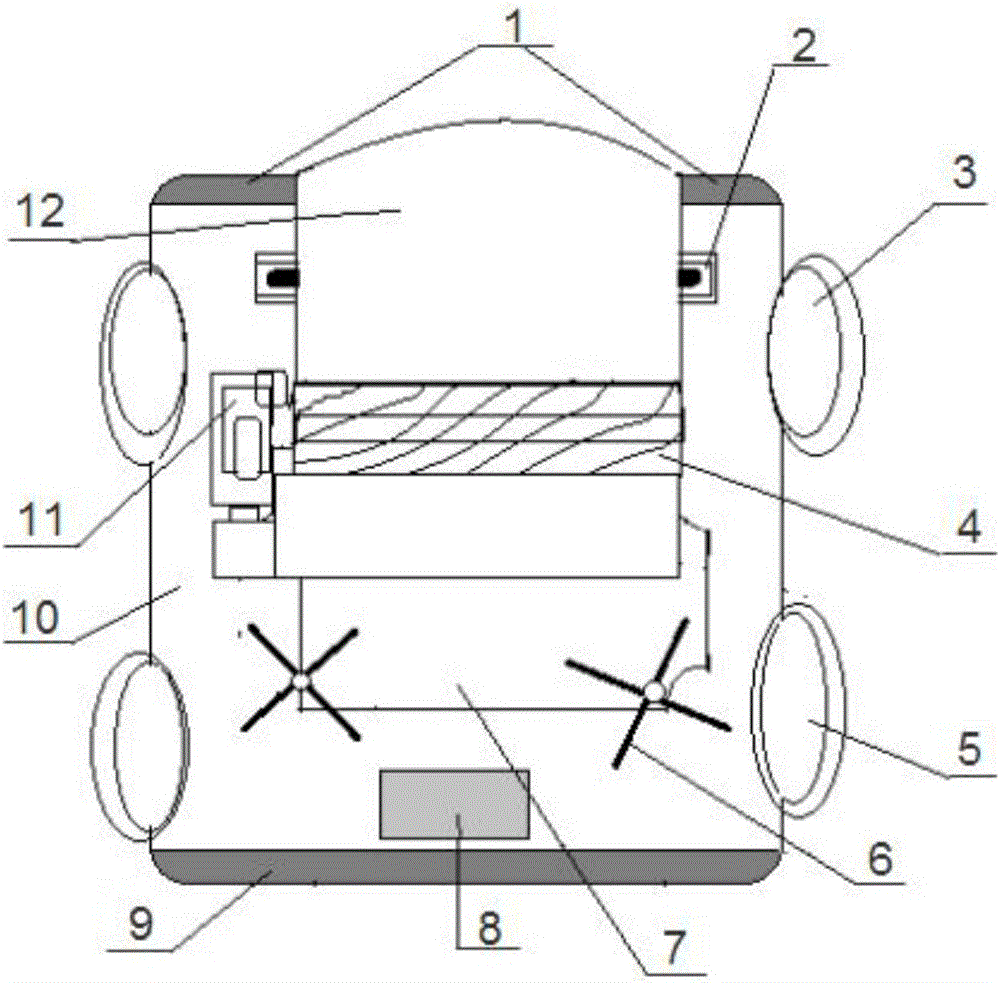

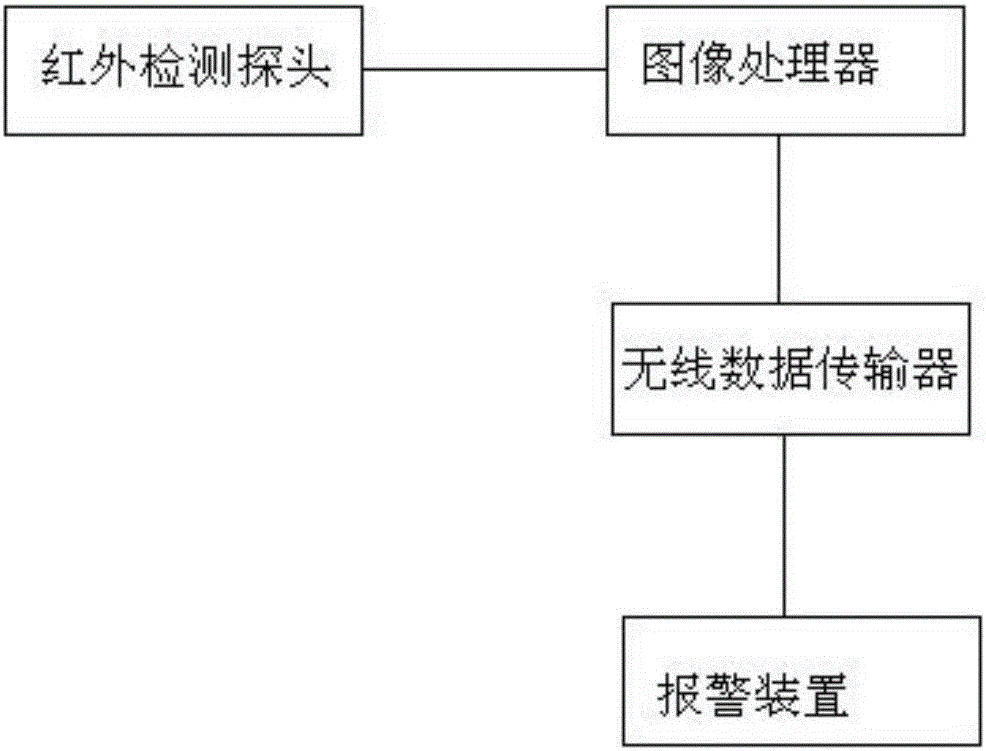

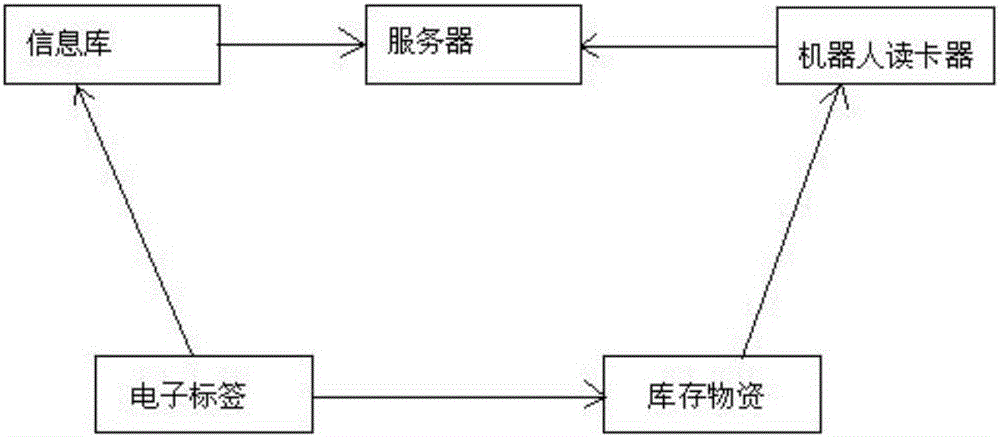

[0015] A warehousing robot that automatically patrols, cleans and counts materials, such as figure 1 As shown, including the robot chassis 10, two front wheels 5 and two rear wheels 3 are respectively installed on both sides of the chassis, and a front-end infrared detection device 9 to ensure the reliability of inspection is installed on the front end of the chassis. A card reader 8 for reading material electronic tag information is instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com