Robot system

A robot system and robot technology, applied in the field of robot systems, can solve the problems of poor operation performance, increased influence of vibration, and increased position of the center of gravity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach >

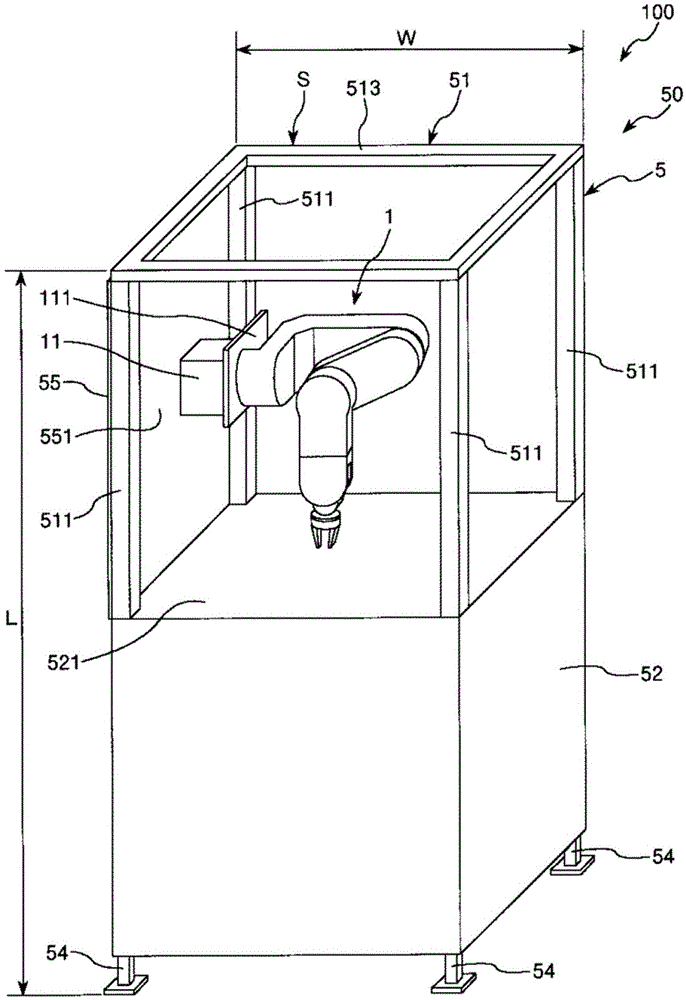

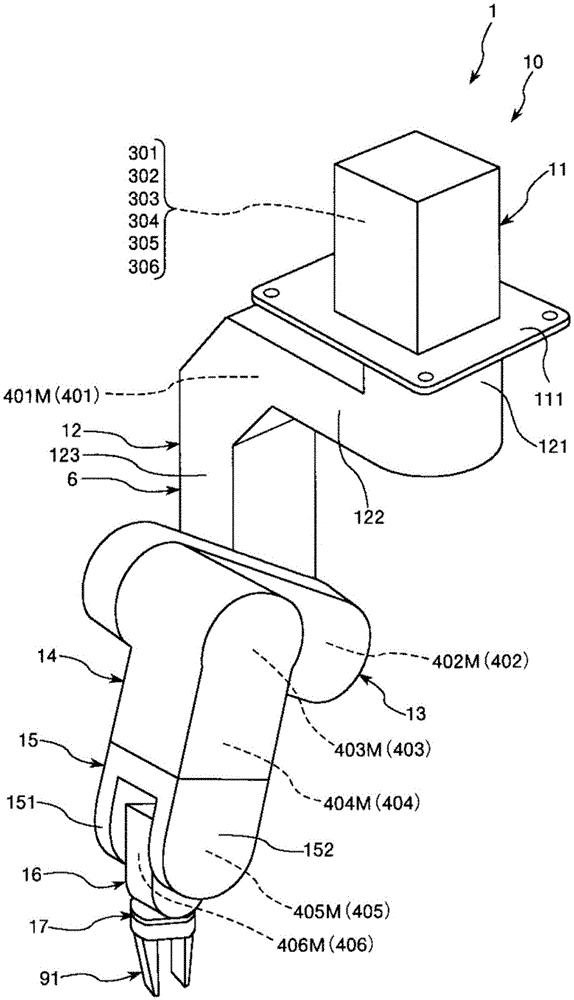

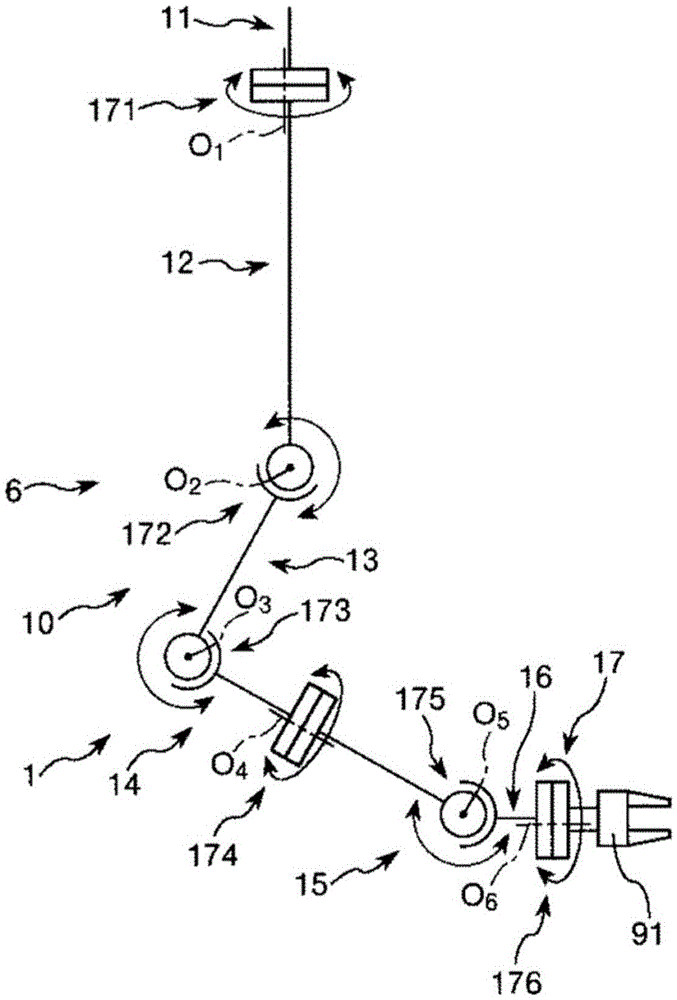

[0052] figure 1 It is a perspective view showing the first embodiment of the robot system of the present invention. figure 2 yes figure 1 A perspective view of the robot of the robotic system shown. image 3 yes figure 1 A schematic diagram of the robot of the robotic system is shown. Figure 4 ~ Figure 6 respectively figure 1 A diagram of the robot in the main view of the robot system shown. Figure 7 ~ Figure 11 respectively for the figure 1 A diagram for explaining the operation of the robot in the robot system shown.

[0053] In addition, in the following, for the convenience of explanation, the figure 1 , Figure 4 ~ Figure 11 The upper side is called "upper" or "upper", and the lower side is called "lower" or "below" (other embodiments) Figure 12 to Figure 14 as well). Additionally, the Figure 1 to Figure 11 The abutment side in the method is called "basal end" or "upstream", and the opposite side (hand side) is called "terminus" or "downstream" (other embo...

no. 2 Embodiment approach >

[0114] Figure 12 It is a perspective view showing the second embodiment of the robot system of the present invention. Figure 13 yes Figure 12 A diagram of the robot in the main view of the robot system shown.

[0115] Hereinafter, the second embodiment will be described, but the description will focus on the differences from the first embodiment described above, and the description of the same matters will be omitted.

[0116] Such as Figure 12 as well as Figure 13 As shown, in the robot system 100 of the second embodiment, a mounting portion 552 on which the base 11 of the robot 1 is mounted is formed above the wall portion 55 of the cell 5 in the vertical direction.

[0117] The shape of the mounting portion 552 is not particularly limited, but in this embodiment, it is formed in a triangular prism shape. Moreover, the orientation of the mounting portion 552 Figure 12 as well as Figure 13 The obliquely downward surface 553 is the first surface inclined with res...

no. 3 Embodiment approach >

[0124] Figure 14 It is a perspective view showing the third embodiment of the robot system of the present invention. Figure 15 yes Figure 14 A diagram of the robot in the main view of the robot system shown.

[0125] Hereinafter, the third embodiment will be described, but the description will focus on the differences from the first embodiment described above, and the description of the same matters will be omitted.

[0126] Such as Figure 14 as well as Figure 15 As shown, in the robot system 100 according to the third embodiment, a mounting portion 554 on which the base 11 of the robot 1 is mounted is formed below the wall portion 55 of the cell 5 in the vertical direction.

[0127] The shape of the mounting portion 554 is not particularly limited, but in this embodiment, it is formed in a triangular prism shape. Moreover, the orientation of the mounting portion 554 Figure 14 as well as Figure 15 The obliquely upper surface 555 is the first surface inclined with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com