Precast concrete maintenance method and concrete precast maintenance system

A technology of concrete prefabricated parts and curing system, which can be used in manufacturing tools, ceramic molding machines, etc., and can solve problems such as low maintenance efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

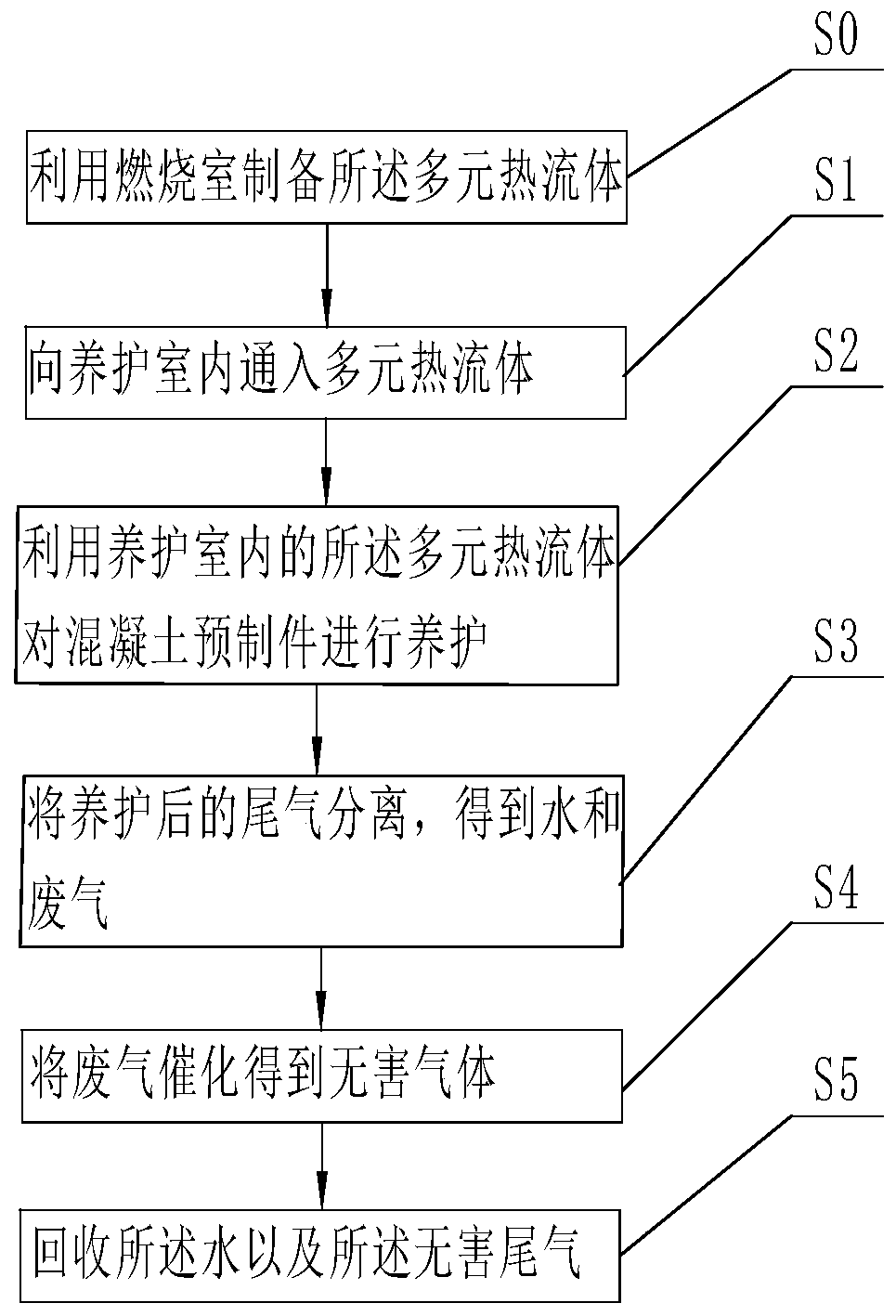

[0028] figure 1 It is the flow chart of the concrete prefabricated part curing method provided by the embodiment of the present invention as follows: figure 1 As shown, the present invention provides a method for curing concrete prefabricated parts, comprising: introducing multi-element thermal fluid S1 into the curing chamber; using the multi-element thermal fluid in the curing chamber to perform curing S2 on concrete prefabricated parts; the multi-element thermal fluid includes at least carbon dioxide and water.

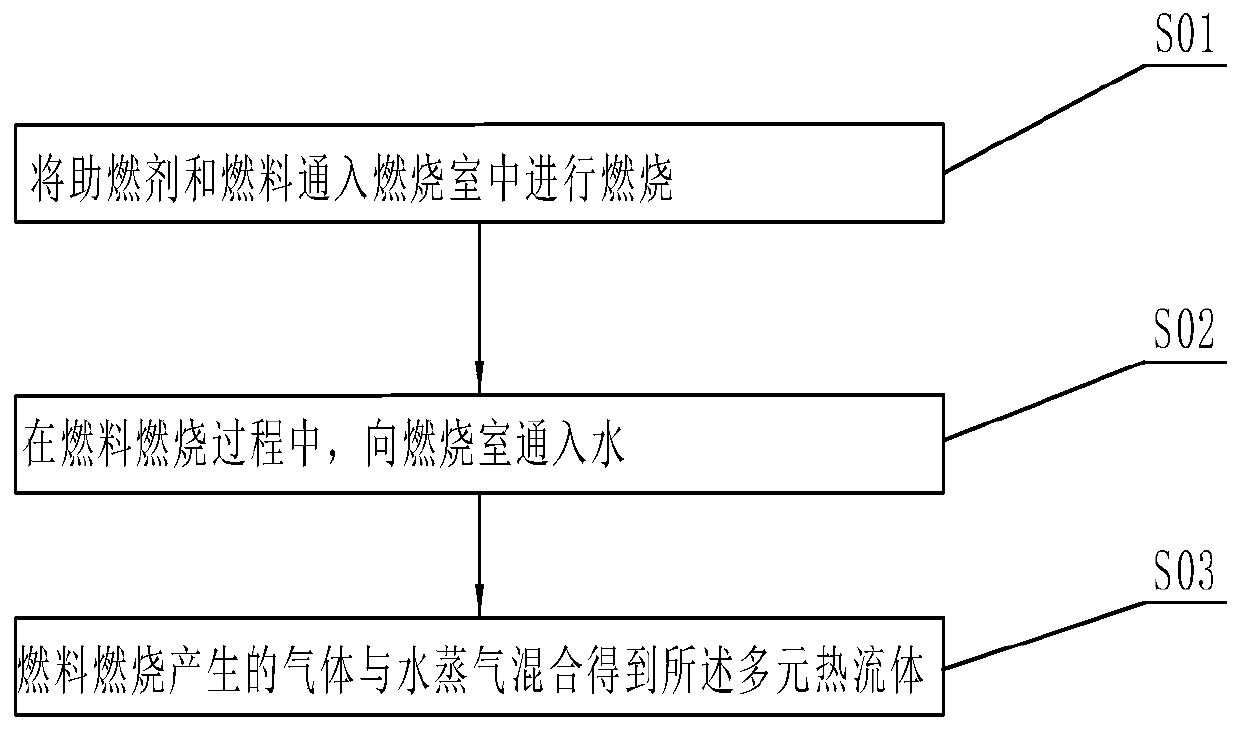

[0029] Among them, there are many ways to obtain multi-component thermal fluid, for example: prepare carbon dioxide and water vapor separately, and then mix carbon dioxide and water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com