A kind of repair mortar and its preparation method and its application in the repair of precast concrete components

A technology of repairing mortar and mixture, which is applied in the repairing of precast concrete components, repairing mortar and its preparation field, can solve the problems of high compressive strength, low strength, short setting time, etc., and achieve flexural strength and bonding High strength, high early strength, strong adhesive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The present invention provides the preparation method of repairing mortar described in above-mentioned scheme, comprises the following steps:

[0039] (1) Portland cement, sulphoaluminate cement and double fast cement are mixed to obtain a cement mixture;

[0040] (2) mixing the cement mixture with redispersible latex powder, expansion agent, early strength agent, rheological agent and defoamer to obtain a cement-auxiliary mixture;

[0041] (3) mixing the cement-auxiliary mixture with quartz sand to obtain a cement-based mortar mixture;

[0042] (4) Mix the cement-based mortar mixture with water to obtain repair mortar.

[0043]The invention mixes Portland cement, sulphoaluminate cement and double fast cement to obtain cement mixture. In the present invention, mixing is preferably carried out under stirring conditions. The present invention has no special requirements on the stirring speed, as long as the Portland cement, sulphoaluminate cement and double-fast cement ...

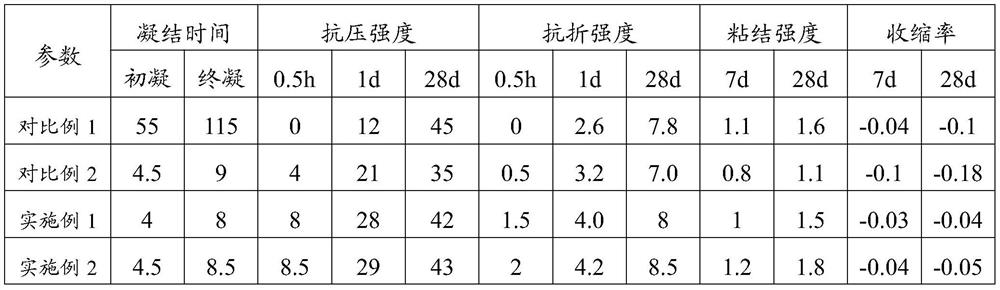

Embodiment 1

[0051] The repair mortar provided by embodiment 1 comprises the following components in weight percentage:

[0052] Portland cement 5%, sulphoaluminate cement 50%, Shuangkuai cement 10%, redispersible latex powder ( 5010N) 1%, expansion agent (anhydrite) 8%, quartz sand 20%, early strength agent (lithium carbonate) 0.3%, rheological agent (naphthalene rheological agent) 0.5%, defoamer (AGITAN P803 ) 0.4%, water 18%.

[0053] The preparation process of the repair mortar is as follows:

[0054] (1) Portland cement, sulphoaluminate cement and double fast cement are mixed to obtain a cement mixture;

[0055] (2) mixing the cement mixture with redispersible latex powder, expansion agent, early strength agent, rheological agent and defoamer to obtain a cement-auxiliary mixture;

[0056] (3) mixing the cement-auxiliary mixture with quartz sand to obtain a cement-based mortar mixture;

[0057] (4) Mix the cement-based mortar mixture with water to obtain repair mortar.

Embodiment 2

[0059] The repair mortar that embodiment 2 provides comprises the component of following percentage by weight:

[0060] Portland cement 10%, sulphoaluminate cement 40%, Shuangkuai cement 20%, redispersible latex powder ( 5010N) 1%, expansion agent (anhydrite) 8%, quartz sand 20%, early strength agent (lithium carbonate) 0.3%, rheological agent (naphthalene rheological agent) 0.5%, defoamer (AGITAN P803 ) 0.4%, water 18%.

[0061] The preparation process of the repair mortar is as follows:

[0062] (1) Portland cement, sulphoaluminate cement and double fast cement are mixed to obtain a cement mixture;

[0063] (2) mixing the cement mixture with redispersible latex powder, expansion agent, early strength agent, rheological agent and defoamer to obtain a cement-auxiliary mixture;

[0064] (3) mixing the cement-auxiliary mixture with quartz sand to obtain a cement-based mortar mixture;

[0065] (4) Mix the cement-based mortar mixture with water to obtain repair mortar.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com