Inorganic early strength type roughening interface agent capable of spraying construction

An early-strength type interface agent technology, which is applied in the field of inorganic early-strength type hair-making interface agent, can solve the problems of uneven roll coating, low efficiency of roll coating construction, and high labor intensity, and achieve good weather resistance and reduce construction cost. Labor intensity and the effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to better explain the present invention and facilitate understanding, the present invention will be described in detail below through specific embodiments.

[0027] An inorganic early-strength type hair-creating interface agent that can be sprayed and constructed includes powder components and liquid components, and the powder components and the liquid components are uniformly mixed in a mass ratio of 2.2-2.5:1.

[0028] Further, the mass ratio of the powder component and the liquid component is 2.5:1.

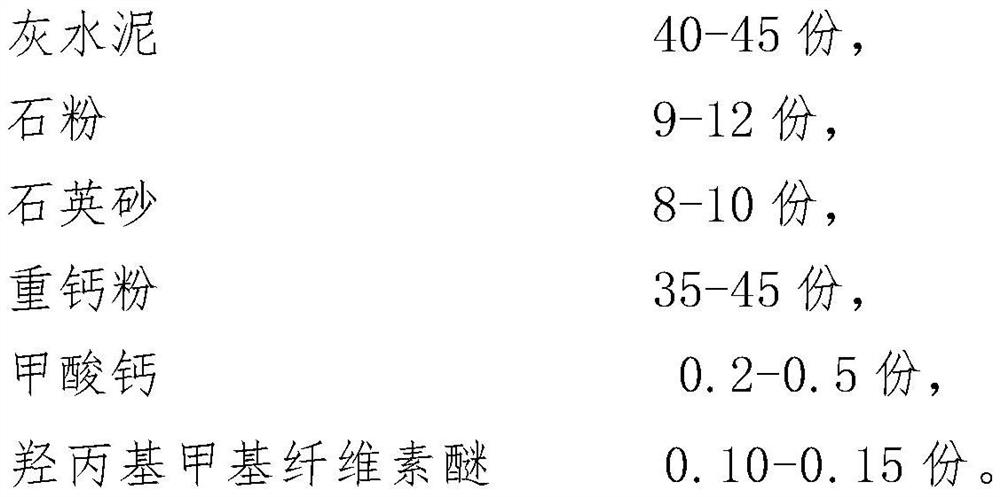

[0029] Further, the powder component is made up of the following raw materials in parts by weight:

[0030]

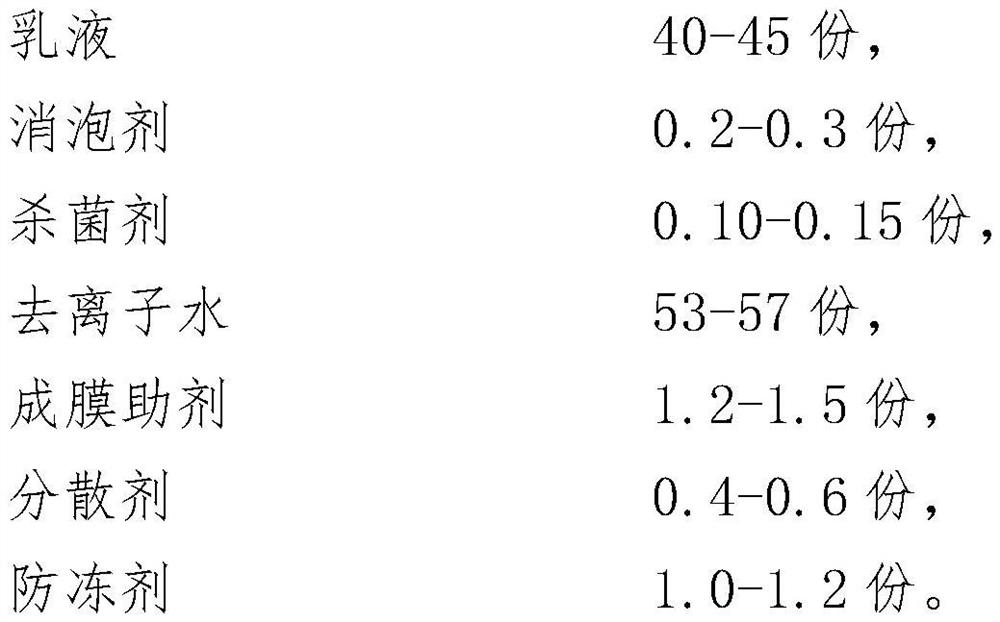

[0031] Further, the liquid material component is made up of the following raw materials in parts by weight:

[0032]

[0033] Further, the grey cement is 42.5 ordinary Portland cement, preferably Conch 42.5 cement or Huaxin 42.5 cement.

[0034] Further, the stone powder is that the silica content is greater than 98%, Fe 2 O 3 ≤0.06-0.02%, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com