a pneumatic punch

A technology of pneumatic punching machines and cylinders, applied in punching machines, presses, manufacturing tools, etc., can solve the problems of limited stroke height, low safety factor, insufficient punching force, etc., to increase punching force, high punching efficiency, and large punching force. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

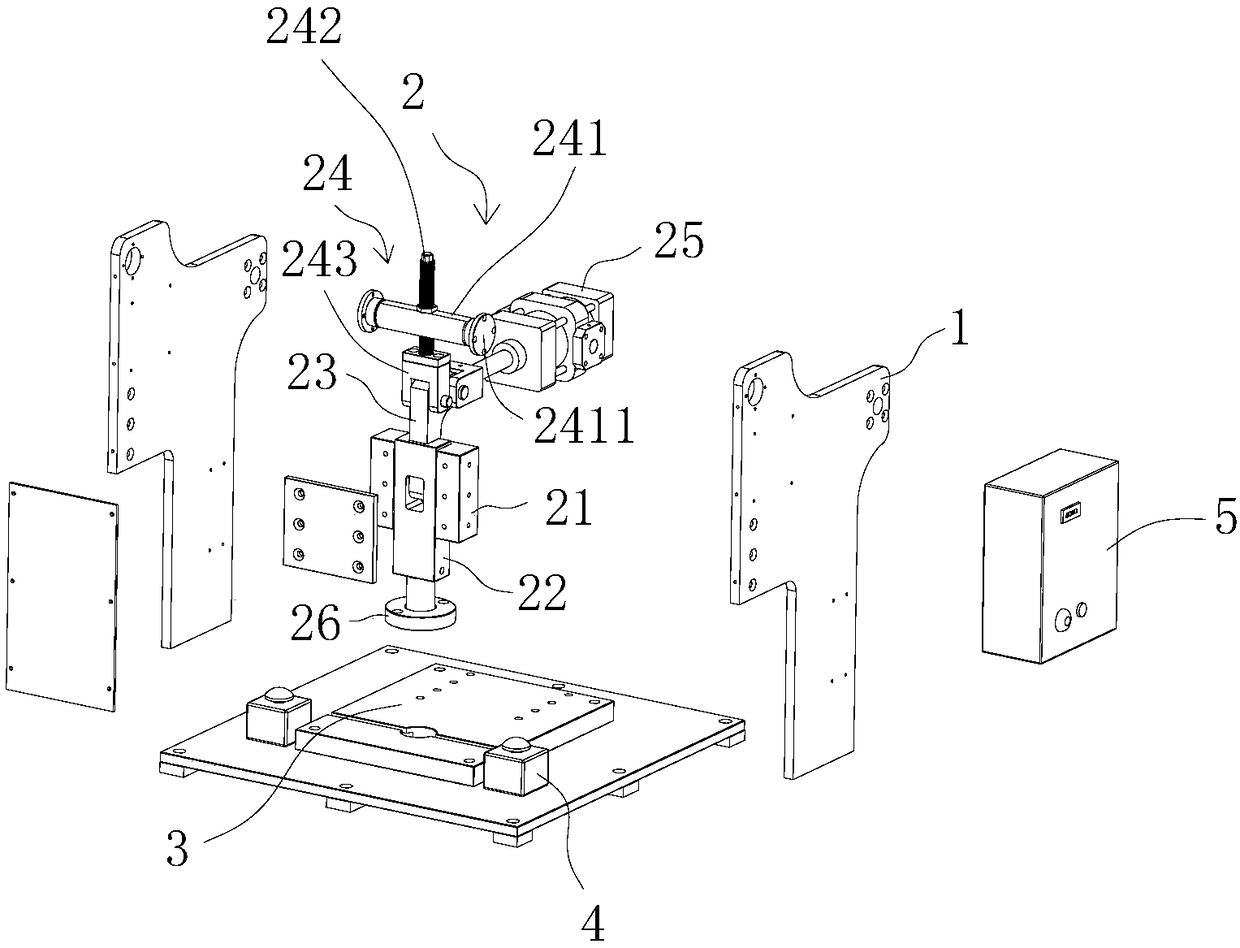

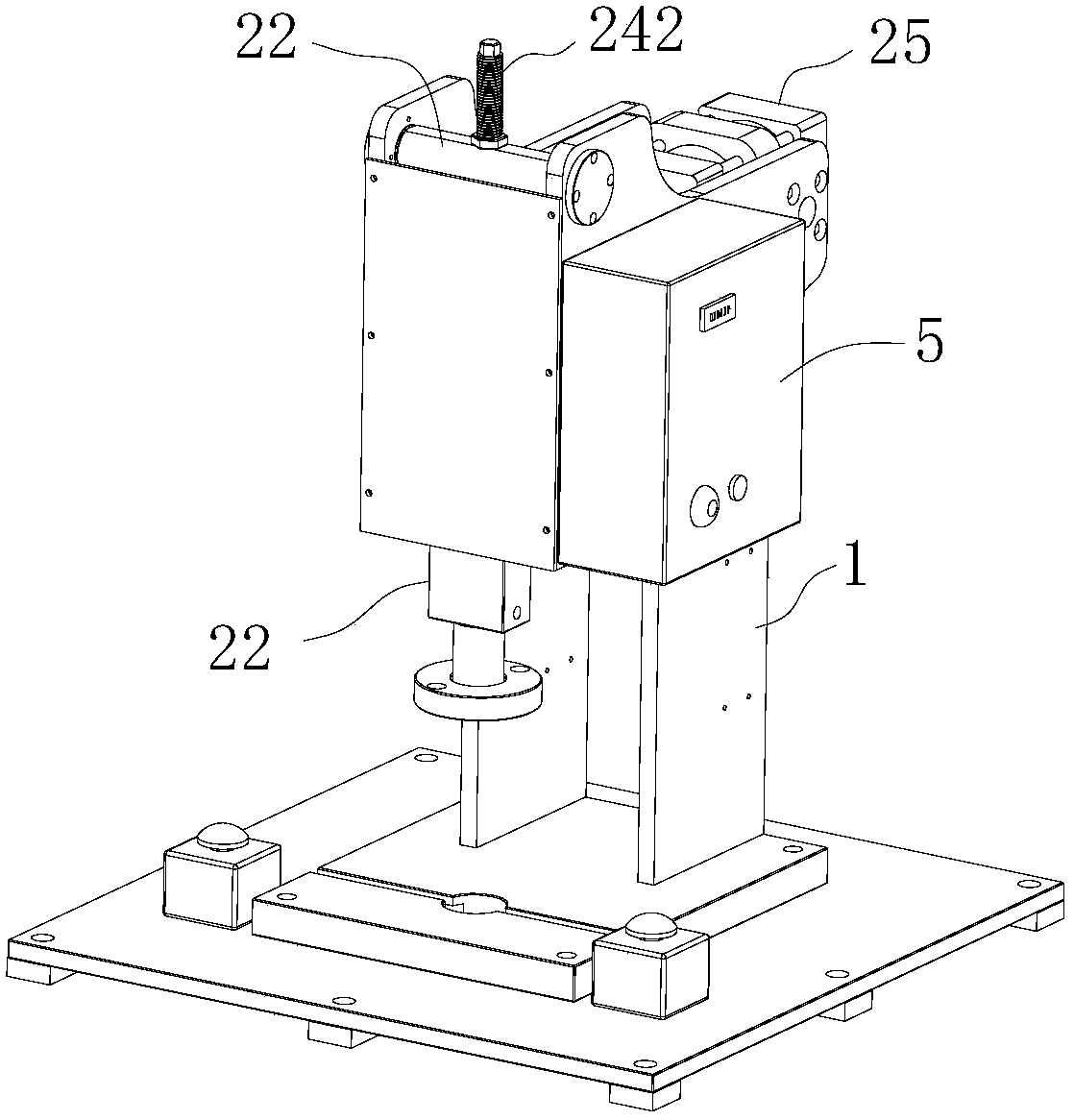

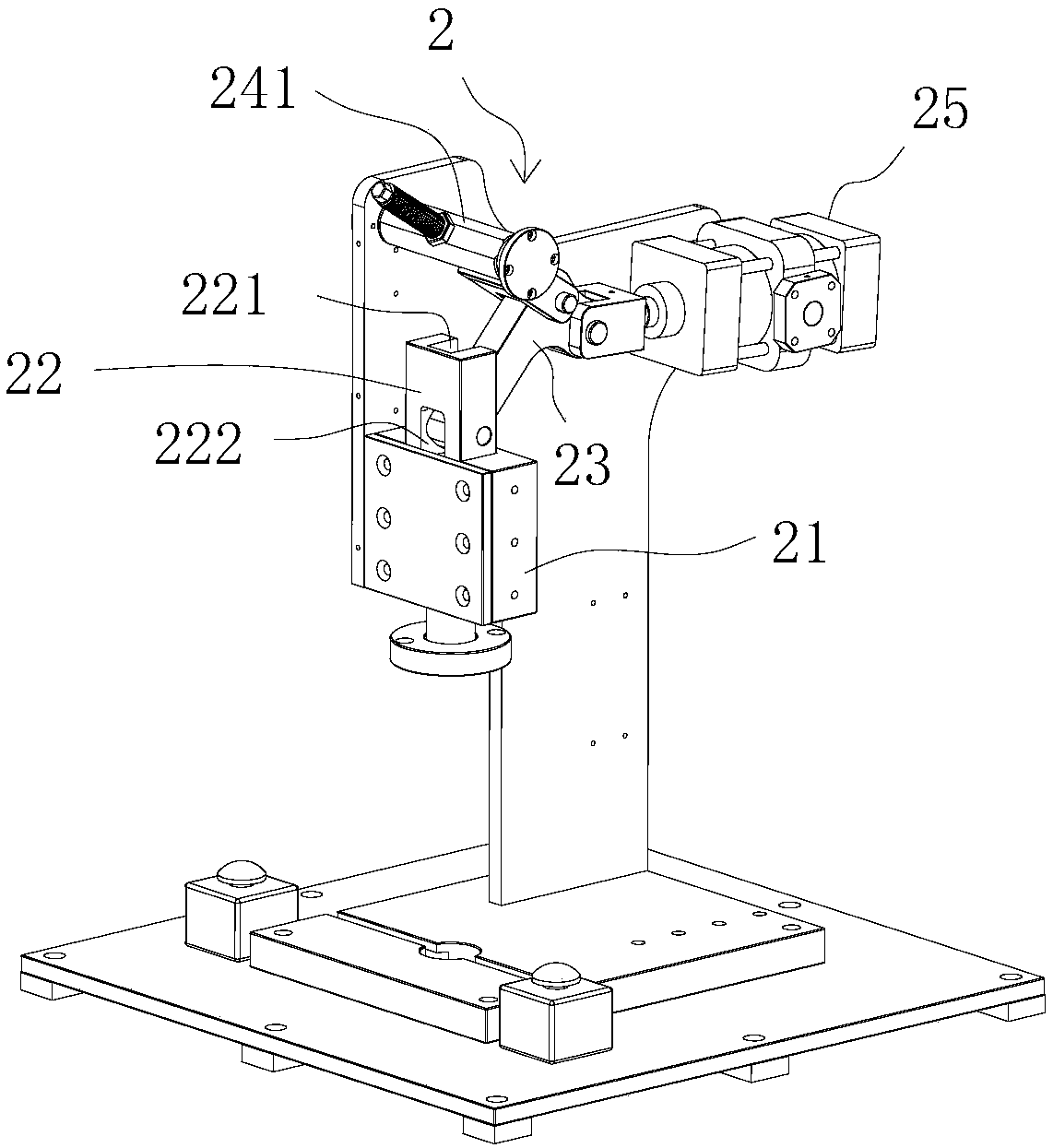

[0019] to combine figure 1 and figure 2 As shown, a pneumatic punch press in this embodiment includes a support frame 1 and a curved arm structure 2 matched with the support frame 1. Rail 21, the slide block 22 that slides with slide rail 21, the curved arm 23 that one end is hinged with the upper end of slide block 22, the stroke adjustment mechanism 24 that is hinged with the bend of curved arm 23, and the hinged arm 23 with curved arm 23 The other end of the cylinder 25 hinged, the lower end of the slide block 22 is provided with a handle 26. With this structural design, the cylinder pushes and pulls one end of the crank arm to drive the slider to slide up and down along the slide rail, thereby forming a large punching force.

[0020] Specifically, in this embodiment, the stroke adjustment me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com