Method and device for acquiring rotor position of direct-drive ball mill permanent magnet synchronous motor

A permanent magnet synchronous motor, rotor position technology, applied in the direction of electromechanical devices, electrical components, electric components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

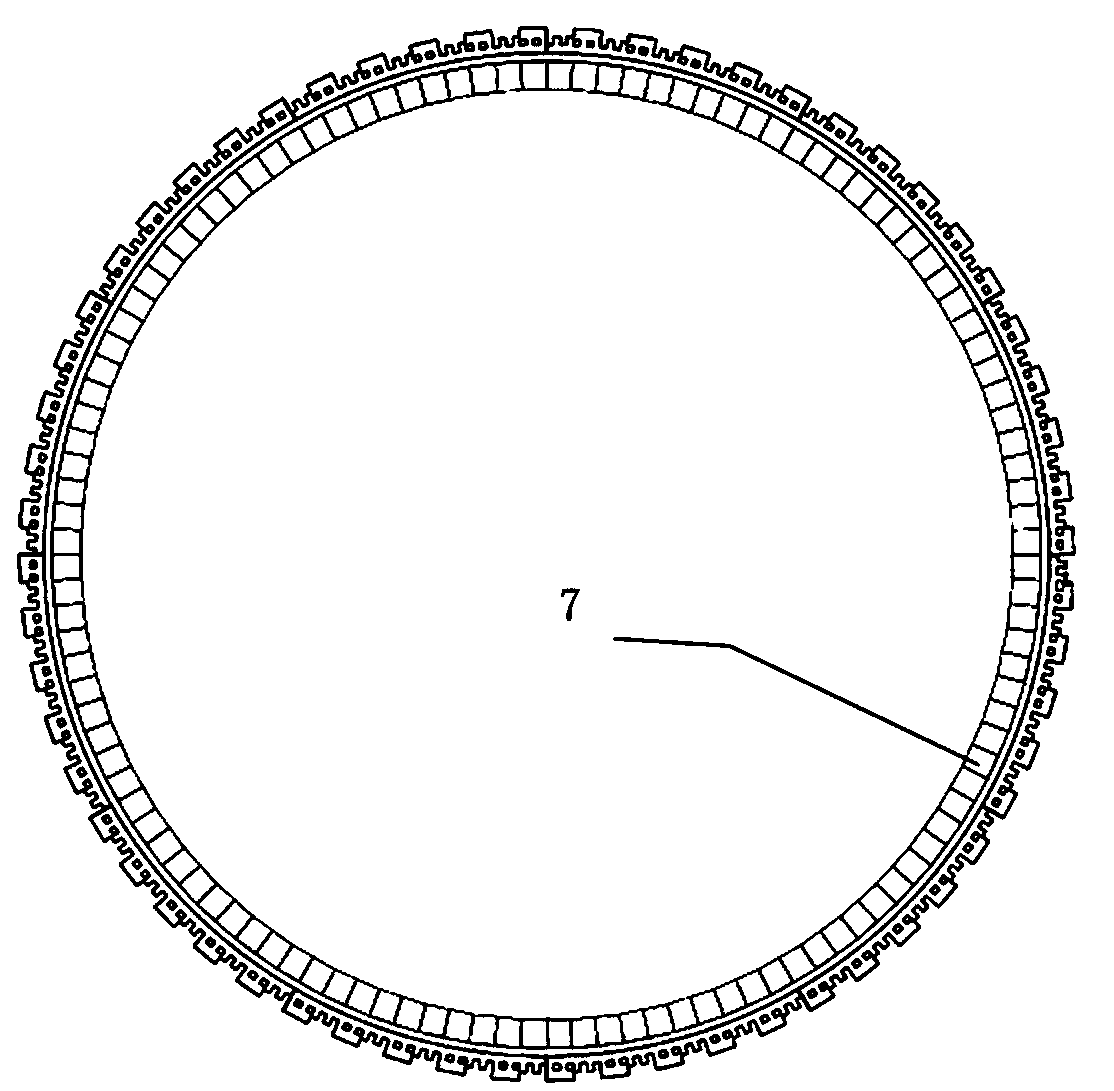

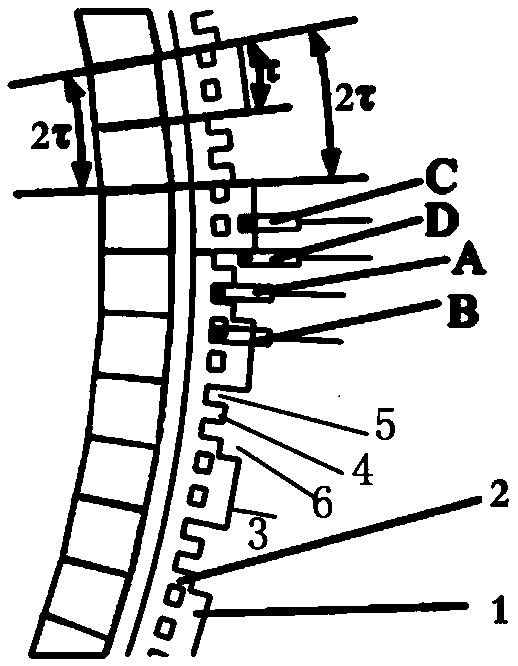

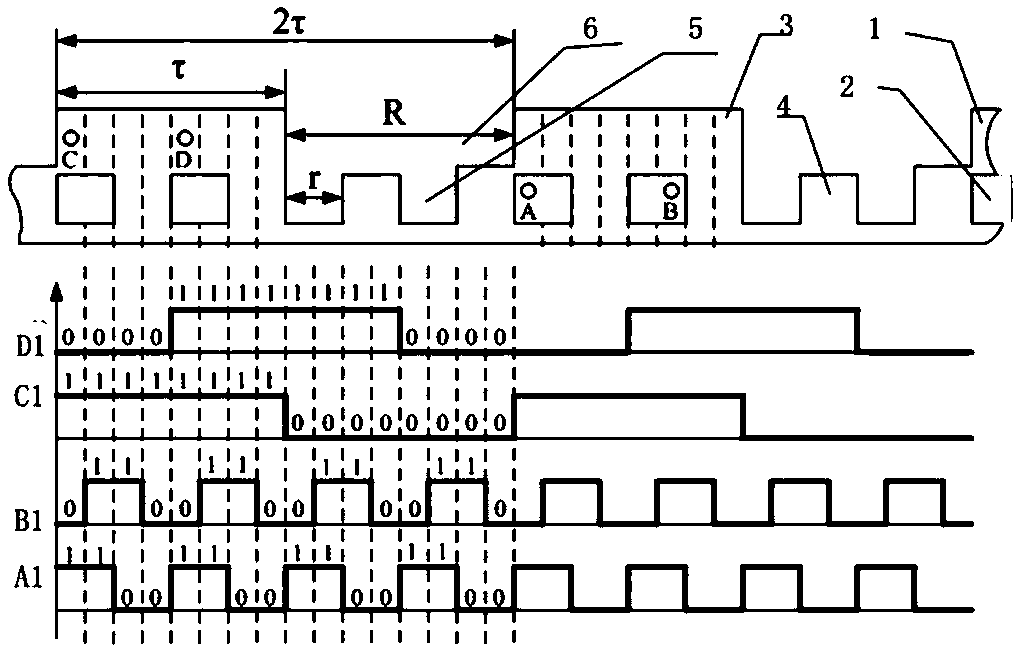

[0031] The direct-drive ball mill permanent magnet synchronous motor rotor position acquisition device includes a photoelectric detection unit. The photoelectric detection unit is connected with a position signal processing unit. The position signal processing unit is preferably an MCU. The photoelectric detection unit includes a photoelectric encoder disk and a photoelectric position detector. The position detector is installed on the stator, and the photoelectric encoder disk corresponding to the photoelectric position detector is installed on the rotor; figure 2 and image 3 It is shown that the edge of the photoelectric encoder disc is provided with an encoding ring corresponding to the photoelectric position detector, and the encoding ring includes an inner encoding ring 2 and an outer encoding ring 1; the inner encoding ring 2 includes the first fan ring imaginary part 5 and the first fan ring real part 5. The first fan ring imaginary part 5 and the first fan ring real ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com