Organic electroluminescent device

An electroluminescent device, an organic technology, applied in the direction of electroluminescent light sources, electric solid-state devices, electric light sources, etc., can solve the problems of inability to use in large quantities, poor stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074]

[0075] Synthesis of intermediate 1c

[0076] In the reaction flask, add 1a (240.00g, 0.88mol), 1b (496.32g, 1.76mol), Pd (PPh 3 ) 4 (20.35g, 17.60mmol), potassium carbonate (302.52g, 2.20mol), toluene (2400mL), pure water (1200mL). After pumping nitrogen for three times, turn on the heating, wait until the temperature of the reaction solution reaches 95-105°C, keep the temperature for 8-12 hours, take samples for TLC and HPLC, and the reaction of the raw materials is complete. Stop heating, lower the temperature to 20-30°C, filter with suction, separate the organic layer from the filtrate, extract the water layer with ethyl acetate, combine the organic layers, wash with water, dry over anhydrous magnesium sulfate, filter with suction, and concentrate the filtrate to obtain dark yellow Solid crude product. Petroleum ether was recrystallized to obtain an off-white solid product with a yield of 90% and a purity of 95%.

[0077] Synthesis of intermediate 1d

[007...

Embodiment 2

[0089] Synthesis of Compound 3

[0090]

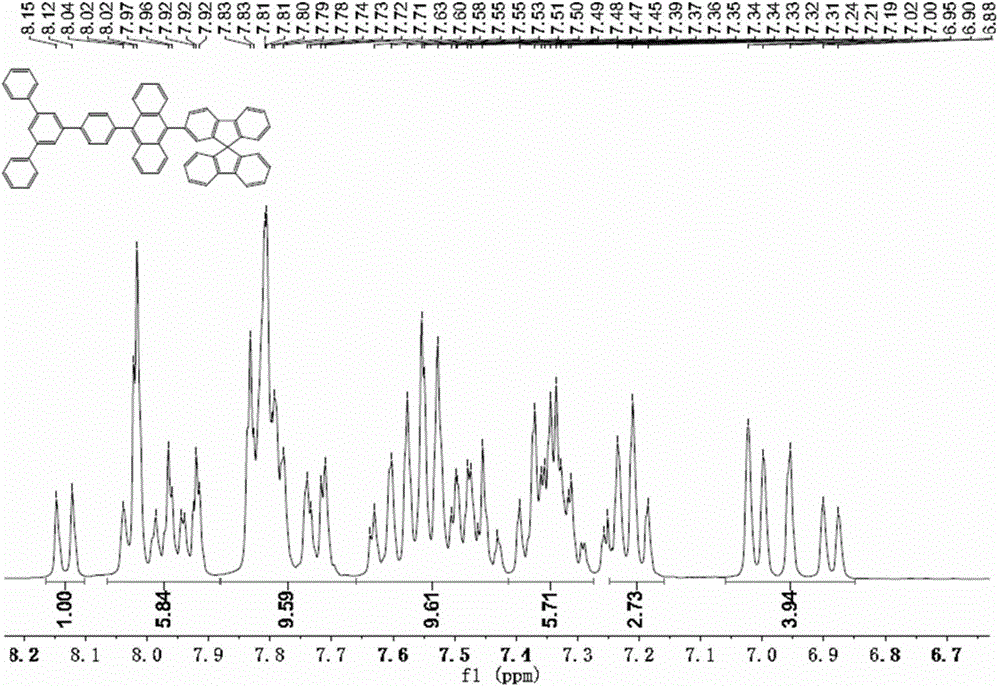

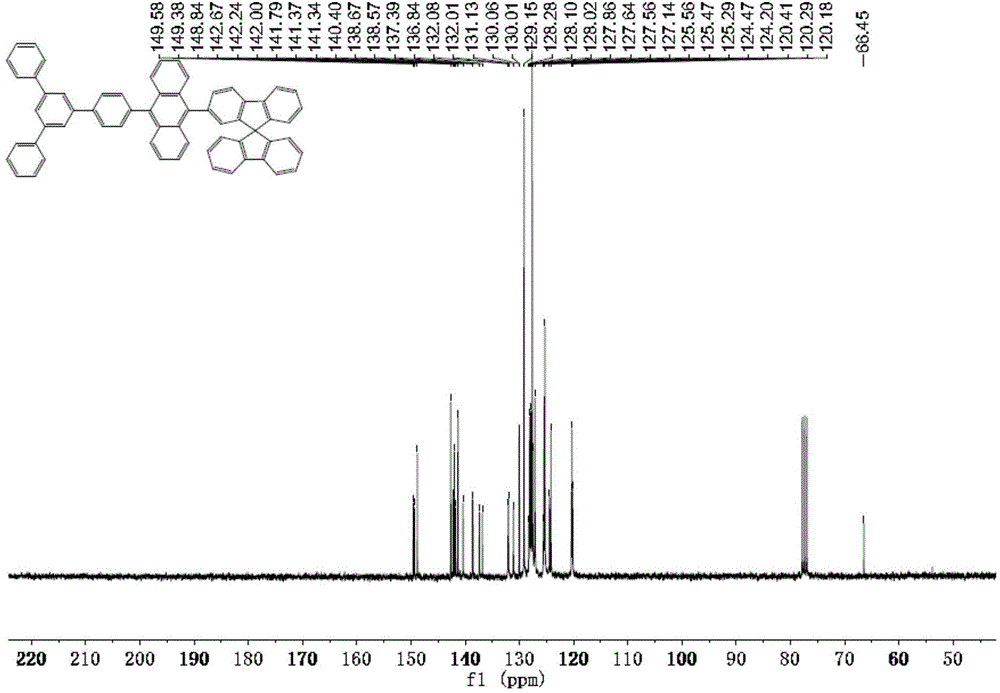

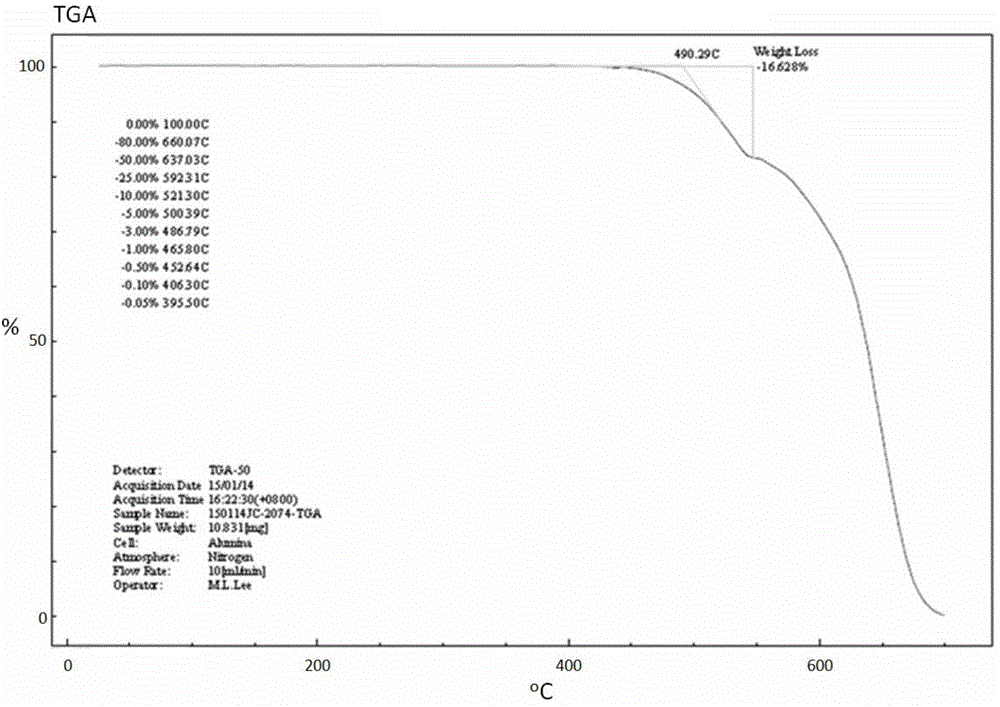

[0091] 1g (9.5g, 16.92mmol), 3a (7.25g, 30.46mmol), Pd (PPh 3 ) 4 (1.5g, 1.3mmol), potassium carbonate (5.84g, 42.3mmol), toluene (150mL), pure water (75mL). The reaction was carried out at 105°C after pumping nitrogen three times. The stop reaction time was detected by the liquid phase, about 12h or so. At the beginning of the reaction, the reaction solution was the khaki color of the catalyst, and then gradually turned into a yellow solution. After the reaction was stopped, the upper layer was clear and light yellow, and the lower layer was water. After stopping the reaction, filter, wash the filter residue with ethyl acetate until there is no product in the filter residue, collect the filtrate, spin dry, a large amount of off-white solid precipitates, collect the filter residue and dry it to obtain the target product with a purity of 98%. The off-white solid powder with a purity of 99.7% was obtained by vacuum sublimation.

...

Embodiment 3

[0094] Synthesis of Compound 89

[0095]

[0096] 1g (10.0g, 17.8mmol), 89a (7.1g, 19.6mmol), Pd (PPh 3 ) 4 (432.2mg, 0.35mmol), K 2 CO 3 (6.14g, 44.5mmol), toluene (300mL) and water (150mL), deoxygenate the device, pass nitrogen protection, and then heat to 100°C to react overnight. Use the ratio of DCM:PE=1:5 to spot the plate, and the product spots will emit strong blue light under the ultraviolet lamp with a wavelength of 365nm, and the Rf value is about 0.2. The reaction solution was filtered with silica gel, then the filter cake was washed twice with ethyl acetate (100mL), separated, the aqueous layer was extracted once with ethyl acetate (100mL), the organic layers were combined, and the organic layer was washed once with water (200mL). Mutually. Spin dry to remove solvent. The crude product was recrystallized with 120ml of DCM / MeOH, and suction filtered to obtain 13.1g of yellow solid powder with a purity of 98.7% and a yield of 92.2%. Vacuum sublimation gave...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap