Refrigeration system using pressurized tank with constant pressure of liquid refrigerant before thermal expansion valve

A technology of thermal expansion valve and liquid refrigerant, which is applied in the direction of machines that use waste heat, refrigerators, refrigeration components, etc. It can solve the problems of raising the condensation temperature and the refrigeration device cannot fully utilize the ambient temperature efficiency, so as to eliminate pressure loss, Improve cooling efficiency and reduce power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

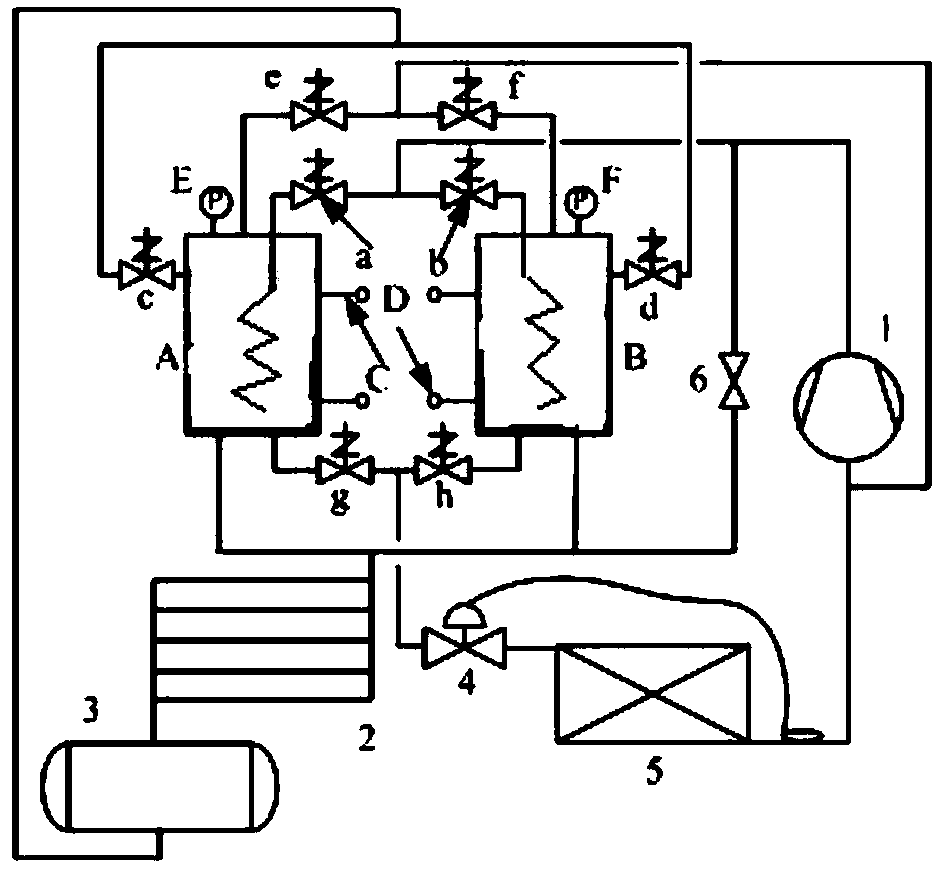

[0011] The present invention will be further described below in conjunction with the accompanying drawings.

[0012] A refrigeration system using a pressurized tank to keep the pressure of the liquid refrigerant before the thermal expansion valve, when the ambient temperature is lower than 25°C, the shut-off valve 6 is closed, and a pressurized tank is used to increase the pressure of the refrigerant in front of the thermal expansion valve; when the ambient temperature rises When the temperature reaches 25°C, the shut-off valve (6) is opened, and the refrigeration system operates normally.

[0013] The refrigeration system using a pressurized tank to keep the pressure of the liquid refrigerant in front of the thermal expansion valve, in order to ensure the continuous liquid supply of the refrigeration system, two pressurized tanks are used: pressurized tank A and pressurized tank B, the working status of the two is different, one to The evaporator feeds the liquid, and the oth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com