Feeding system for settling tank

A feeding system and settling tank technology, applied in the field of separation, can solve the problems of wasting flocculants, increased production costs, and low solid content in the underflow, and achieve the effects of improving the efficiency of sedimentation separation, prolonging the residence time, and increasing the solid content in the underflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

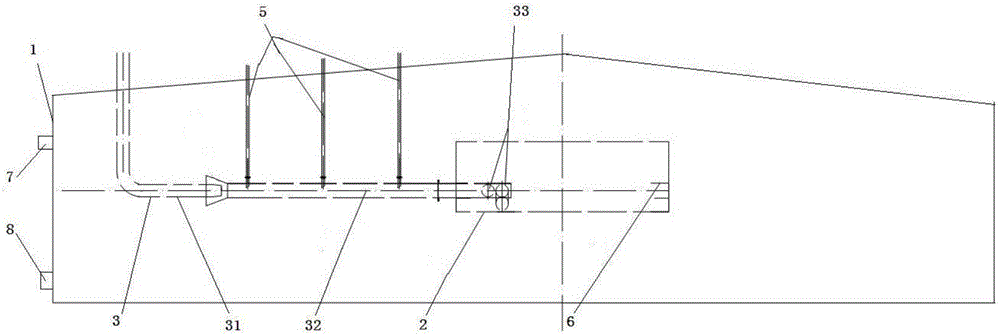

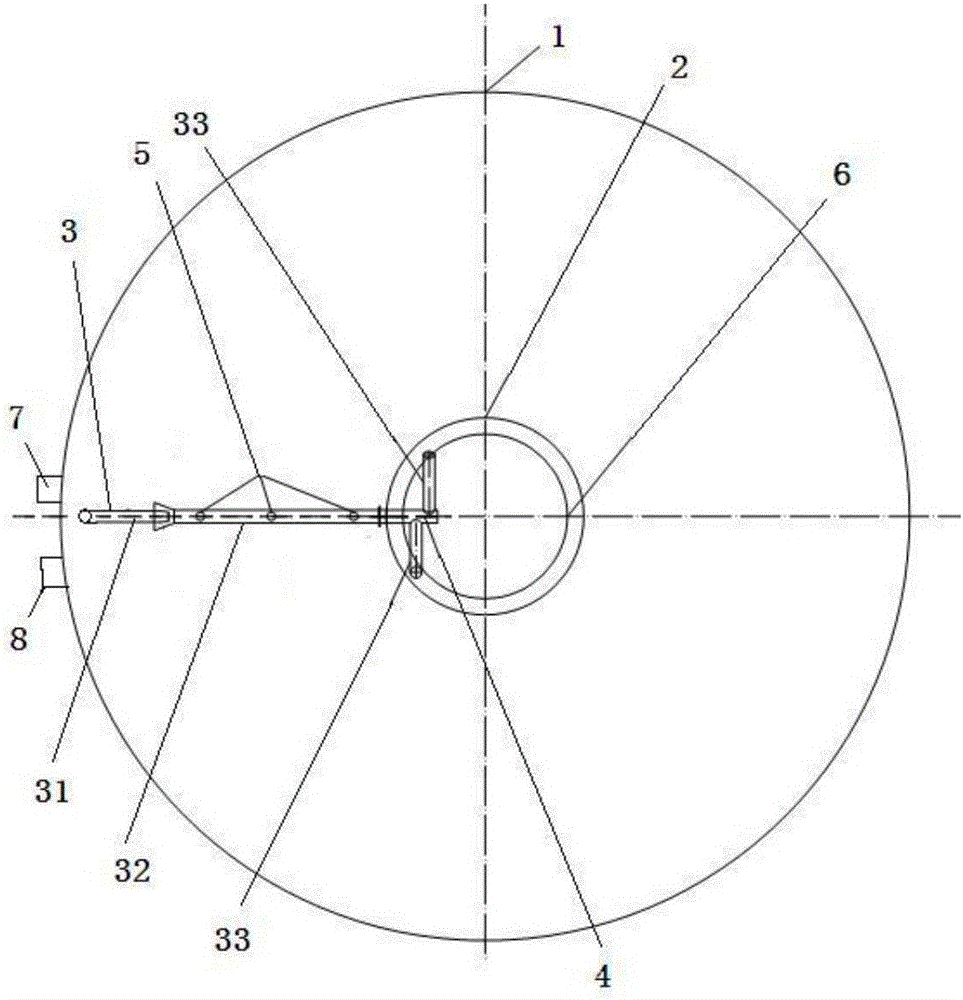

[0037] See Figure 1-Figure 3 , A feeding system for a settling tank, comprising a feeding connecting piece 3, the feeding connecting piece 3 comprising a front feed pipe 31 communicating with an external feeding device, and a rear section communicating with the front feeding pipe 31 The feed pipe 32 and the two feed pipes 33 both connected with the rear feed pipe 32, the outlet end of the rear feed pipe 32 and the feed pipe 33 are coaxially arranged in the settling tank Inside the central barrel 2 inside the tank body 1, the inlet ends of the front-stage feeding pipe 31 and the rear-stage feeding pipe 32 are located outside the central barrel 2 and inside the settling tank body 1 .

[0038] The upper part of the sedimentation tank body 1 is provided with an overflow port 7, and the lower part is provided with an underflow outlet 8. The diameter of the sedimentation tank body 1 is Φ15m-40m, and the height is 6m-10m; the diameter of the central barrel 2 is Φ3m- 6m, the height is...

Embodiment 2

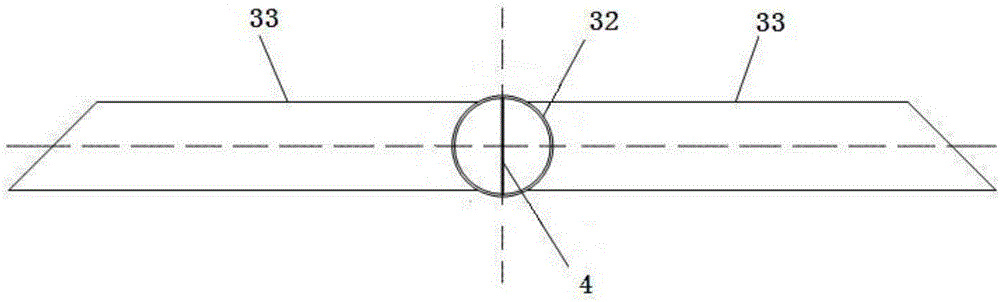

[0049] The difference between this embodiment and the first embodiment is only that the positions of the two feed pipes are different, specifically: the central axis of the rear feed pipe 32 and the central axis of one feed pipe 33 are located at A On the plane, the central axis of the rear feed pipe 32 and the central axis of the other feed pipe 33 are located on the B plane, and the A plane and the B plane are two different planes. The angle between the central axis of the tube 33 is 15°, see Figure 4 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com