Combination frames, partitions and doors and windows with preset holes

A technology of preset holes and combination frames, which is applied in the installation of window glass, walls, buildings, etc., can solve the problems of difficult to control the accuracy of threaded holes, inconvenient installation, and poor correspondence between bolts and threaded holes, and achieve a simple structure. , The effect of reducing the installation process and reducing the number of fasteners

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

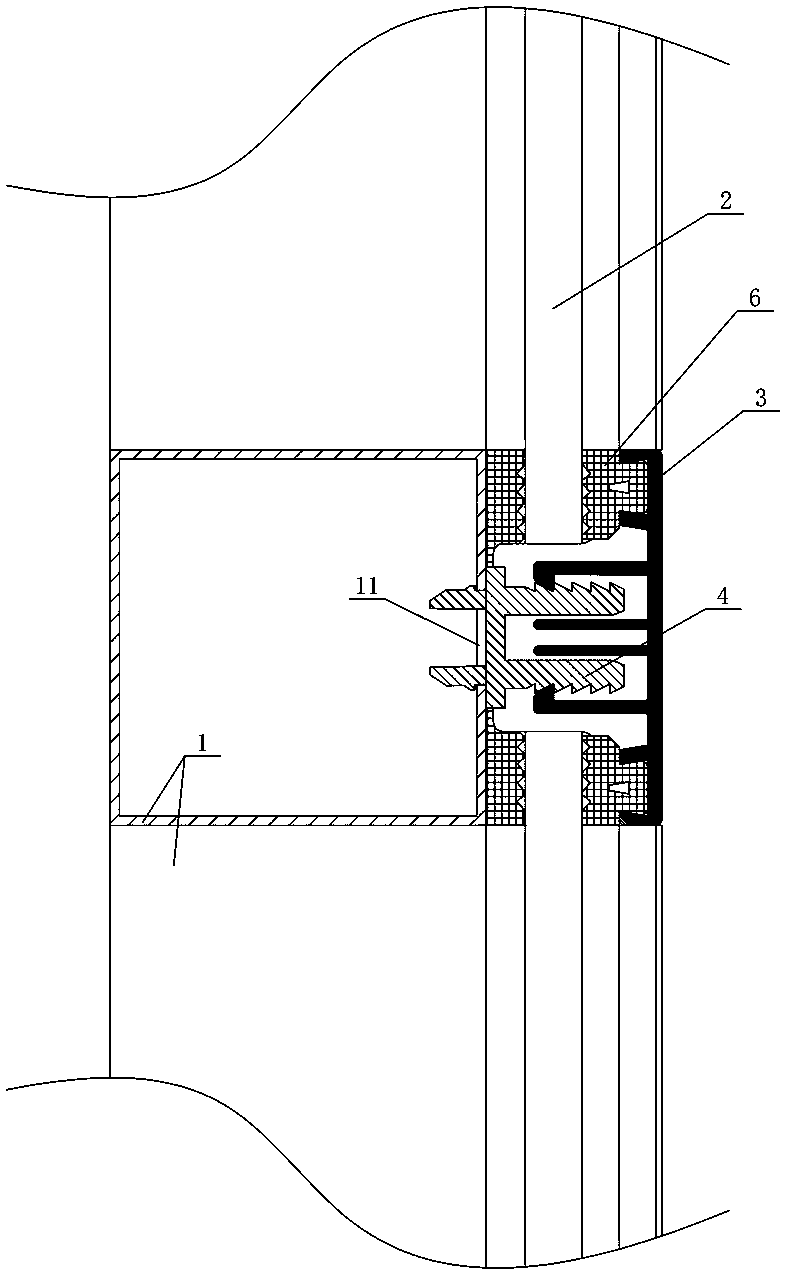

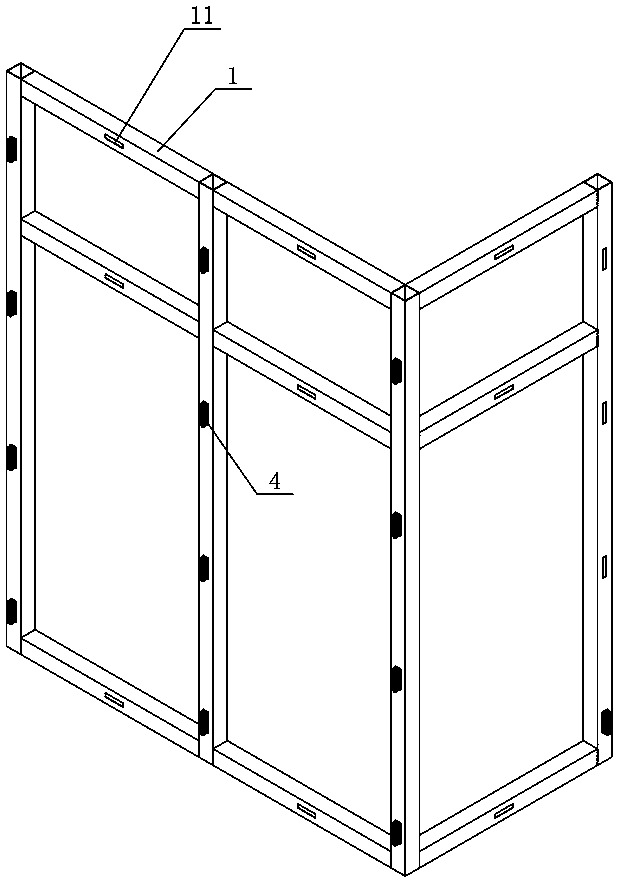

[0034] Figure 1 to Figure 5 It shows the first embodiment of the composite frame body with preset holes in the present invention, the composite frame body includes a keel frame 1 and a pressing plate 3, and a plurality of preset holes 11 are evenly opened on the keel frame 1, and inside the preset holes 11 A fastener 4 extending to the outside is buckled, and a pressing plate 3 for pressing the panel 2 on the keel frame 1 is fastened on the fastener 4 . During installation, the keel frame 1 is installed first, and then each fastener 4 is selectively connected with the preset hole 11, and then the panel 2 is attached to the keel frame 1, and the pressing plate 3 is formed with each fastener 4 at the same time. Fasten and make the pressure plate press the panel 2 to complete the installation. In this structure, the preset hole 11 can be pre-punched according to the specifications when the keel frame 1 is made, ensuring the accuracy of the buckle point position; during installa...

Embodiment 2

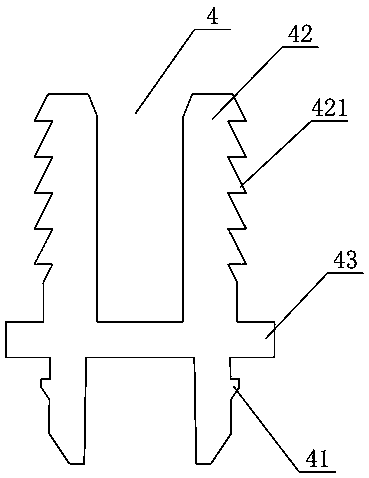

[0042] Figure 6 to Figure 9 Shown is the second embodiment of the combination frame body with preset holes of the present invention, the combination frame body is basically the same as Embodiment 1, the only difference is that: the extension bolt 5 is installed on the extension end of the fastener 4, and the expansion bolt 5 The screw heads of the tightening bolts 5 are pressed on the inner sidewalls of the two limiting plates 43, and the two limiting plates 43 are arranged obliquely. Opening, pressing plate 3 is fastened with the buckle platform 42 after expanding. In this structure, driven by the expansion bolt 5, the fastener 4 can be further expanded to both sides after being installed on the keel frame 1, and the pressure plate 3 is fastened with the expanded buckle platform 42, which greatly improves the overall fastening strength. .

[0043] In this embodiment, the fastener 4 is provided with a pressing platform 44 between the locking platform 42 and the pressing pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com