An injector performance testing device

A testing device and injector technology, applied in jet propulsion device, rocket engine device, machine/engine, etc., can solve problems such as lack of injector performance, improve medium atomization effect, high measurement accuracy, and satisfy measurement requirements desired effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific implementation.

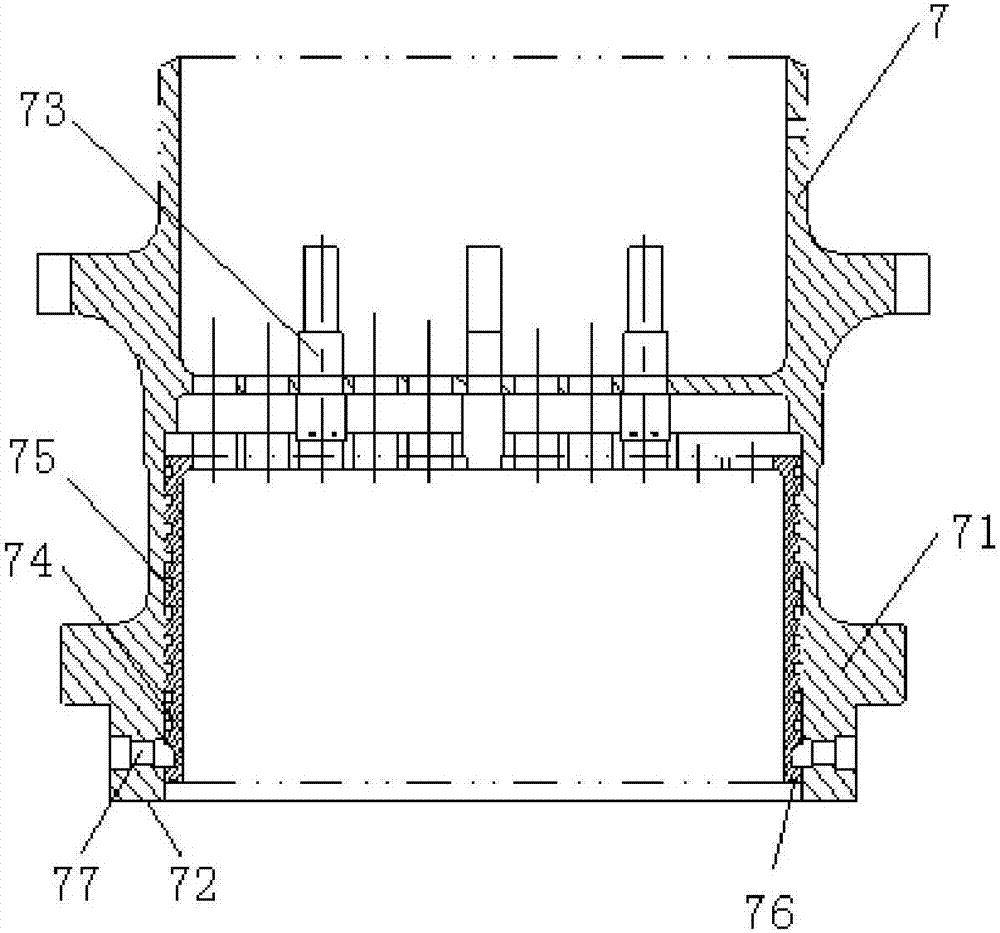

[0050] figure 1Shown is a schematic structural diagram of the injector of the present invention. The injector includes a housing, a plurality of nozzles 73 and an inner bottom 74. The plurality of nozzles 73 are located in the middle of the housing, and the injector is divided into upper and lower parts. The upper part The main fuel road ring cavity, the lower part is the main fuel road outlet cavity, the outer periphery of the lower end near the bottom is provided with a plurality of fuel road inlets 77, the outer periphery of the inner bottom 74 is provided with a spiral groove 75 leading from the bottom of the inner bottom to the top, and the inner bottom There are multiple tangential holes for cooling passages at the bottom of the tank, and the inner bottom is inlaid on the inner wall of the lower shell. The liquid entering fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com