Device for measuring non-uniform coefficient of spray

A measuring device and uniformity coefficient technology, which is applied in the direction of measuring device, testing of mechanical components, testing of machine/structural components, etc., can solve problems such as difficulty in quantifying the effect of spray atomization, improve the effect of medium atomization, and have good versatility , good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

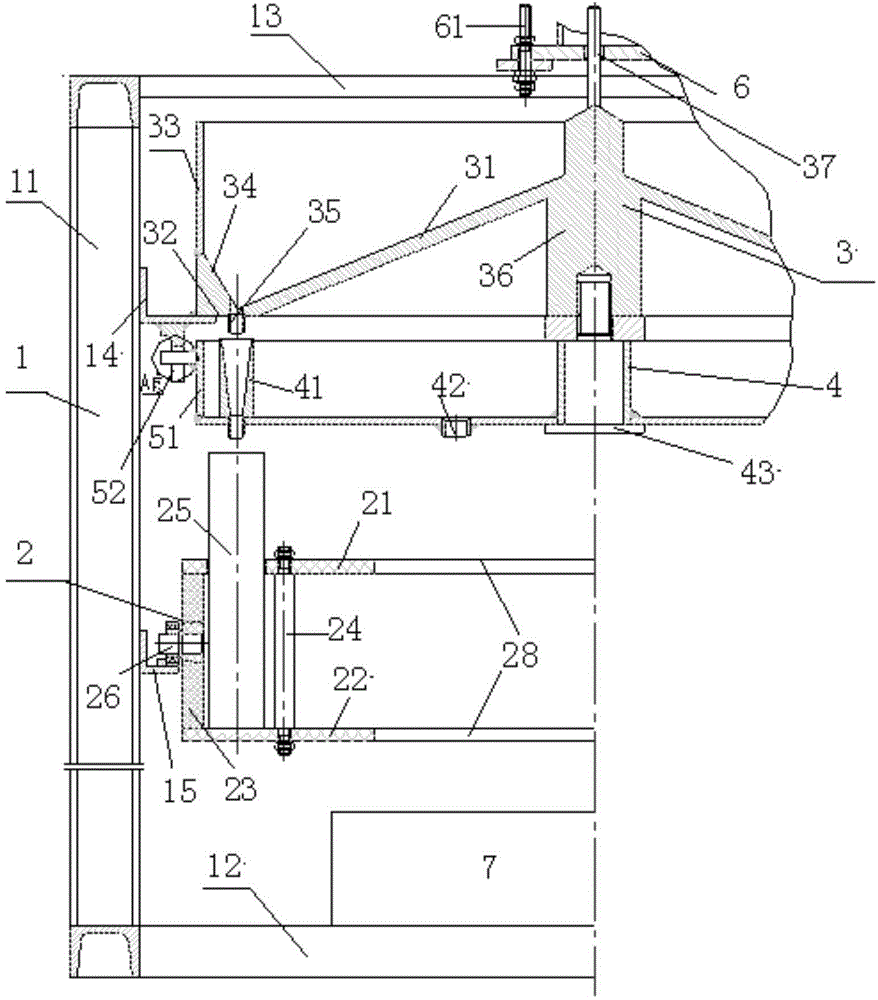

[0043] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0044] The present invention will be described from the design point of view below.

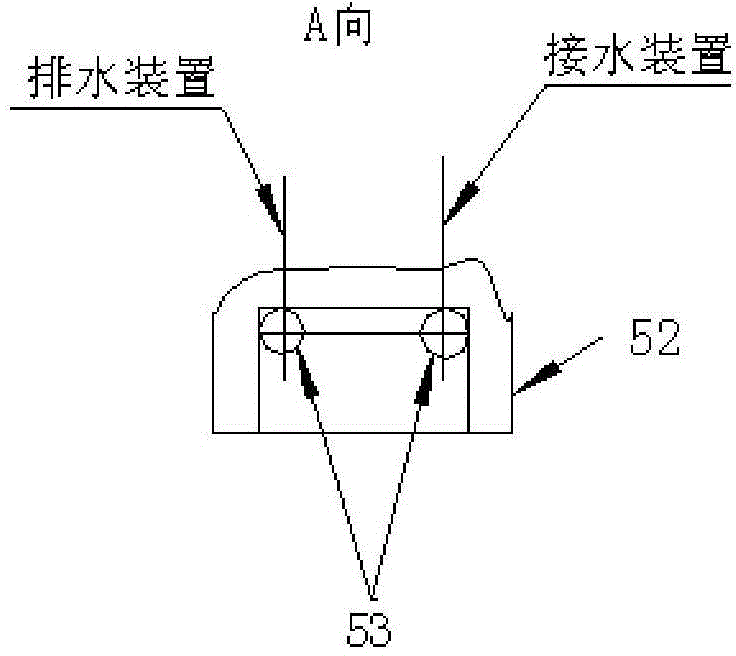

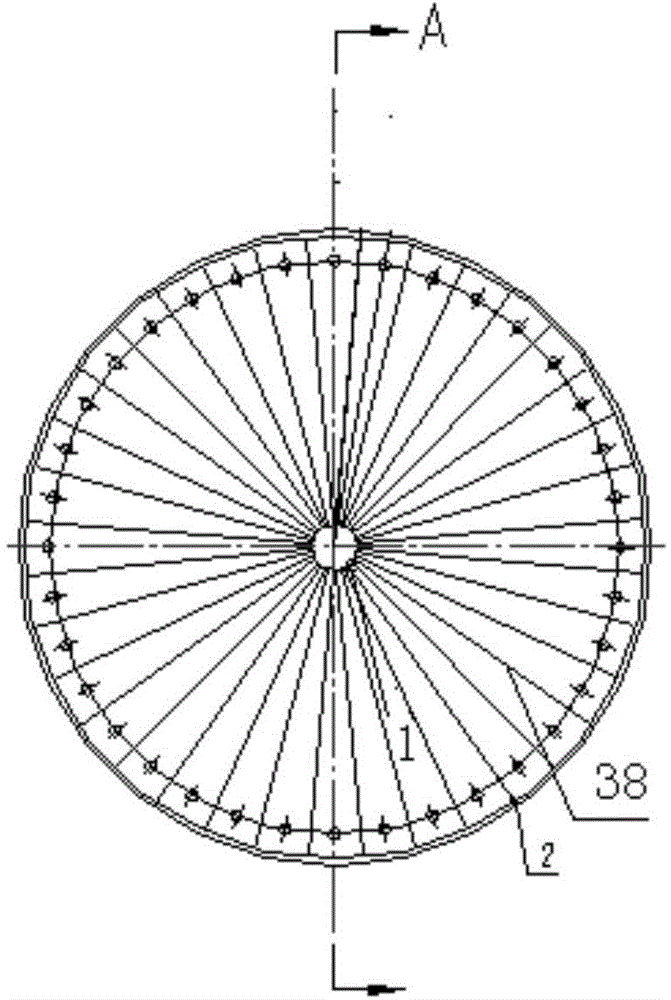

[0045] In order to ensure the convenience and feasibility of the processing of the collection plate 3 receiving the water tank, the present invention selects the scheme of placing the test tubes in a single row around the circumference; considers the convenience of water collection and measurement accuracy, chooses to divide the spray cone into equal parts; considers the versatility of the measuring device for large and small flow rates, according to Calculate the maximum flow rate given by the design and the minimum water collection time, select a suitable test tube, and design the key dimensions of the water receiving tray 4, collecting tray, and stand 1 in sequence, and install them in the following order: a. Separator 38 and collecting tray form ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com