Dynamic and static pressure bearing loading experiment apparatus

A technology of dynamic and static pressure bearing and loading experiment, which is applied in the field of hydraulic power to save costs, avoid installation errors and improve efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to fully explain the technical solution of the present invention, the present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

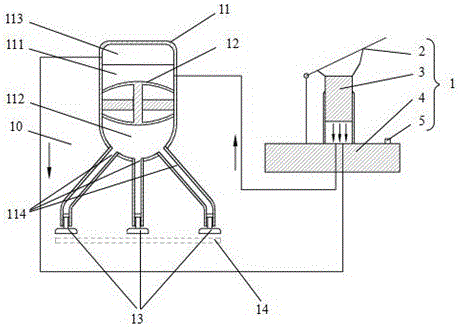

[0016] explain: figure 1 The direction of the arrow shown in is the circulation flow direction of the hydraulic oil.

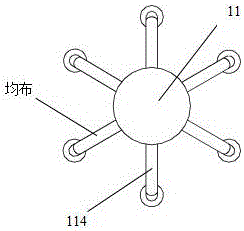

[0017] Such as figure 1 As shown, the embodiment of the present invention provides a dynamic and static pressure bearing loading experimental device. The device includes an oil pumping part (1) and an operating part (10) connected to each other. The operating part (10) includes a cylinder body (11), a two-way pressure shoe (12) and a thrust piston (13). Inside the cylinder body (11) There are a pressurized oil chamber (111), a drive oil chamber (112) and an oil return chamber (113). The pressurized oil chamber (111) is respectively connected with the pump oil part (1) and the oil return chamber (113). The oil chamber (113) communicates with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com