Method and device for monitoring the movements of the forks of a robotized gearbox, by relearning

A technology for automatic gearboxes and control devices, applied in the direction of transmission control, elements with teeth, belts/chains/gears, etc., which can solve problems such as wasting time, unusable, and damaging gearboxes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

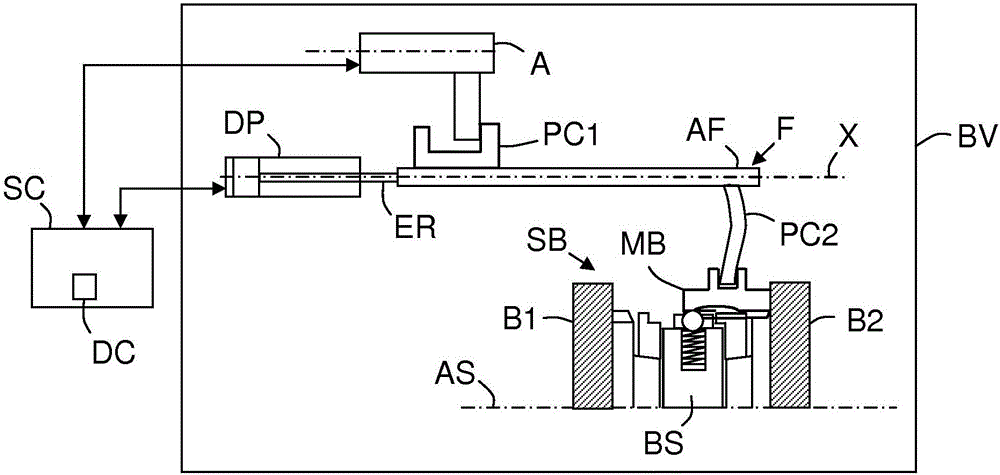

[0034] The object of the invention is in particular to provide a control method and an associated control device DC for being able to control the forced movement of at least one shift fork F as An integral part of the automatic transmission BV and is intended to be fitted on the system.

[0035] In the following, as a non-limiting example, the system is considered to be a motor vehicle, such as a car. But the invention is not limited to this type of system. The invention relates in fact to all types of systems including at least automatic gearboxes BV, in particular land vehicles (of whatever type), sea (or river) vehicles and some (optionally industrial) equipment.

[0036] figure 2 A small part of an automatic transmission BV is schematically shown on FIG. 2 , which is here intended to be coupled via a clutch to an internal combustion engine of a vehicle.

[0037] Although in figure 2 The upper part shows that the gearbox BV conventionally comprises, inter alia, at lea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com