Working method for jig for locking or detaching screws on side faces in two directions

A working method and screw technology, applied in the field of jigs, can solve problems such as unfavorable production efficiency and cost, achieve the effects of fast and convenient use, high positioning accuracy, and reduce the cost of jigs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below with reference to the accompanying drawings and embodiments.

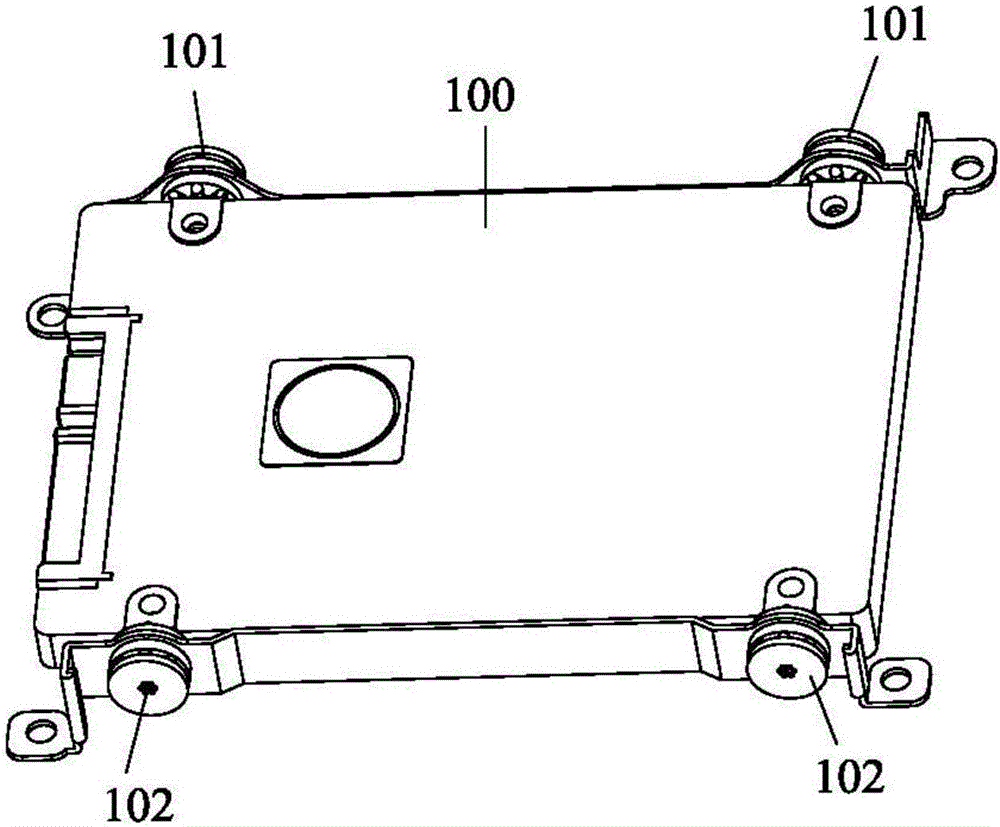

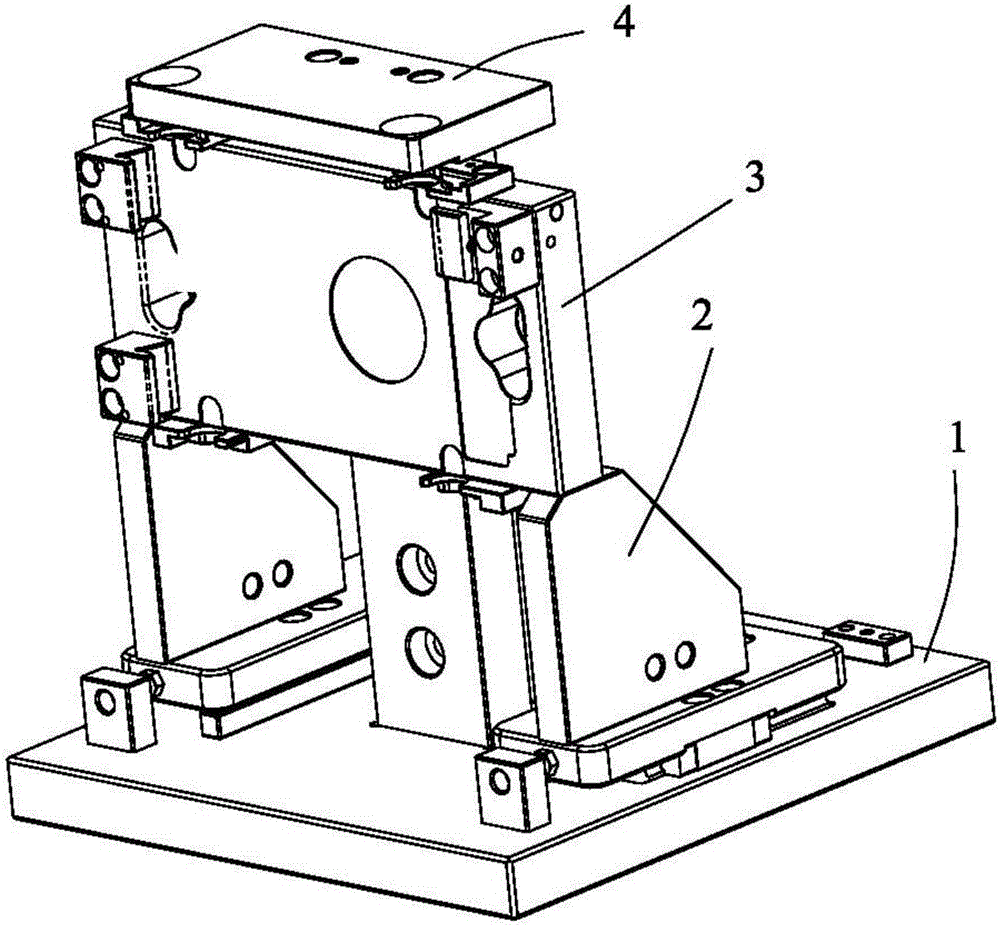

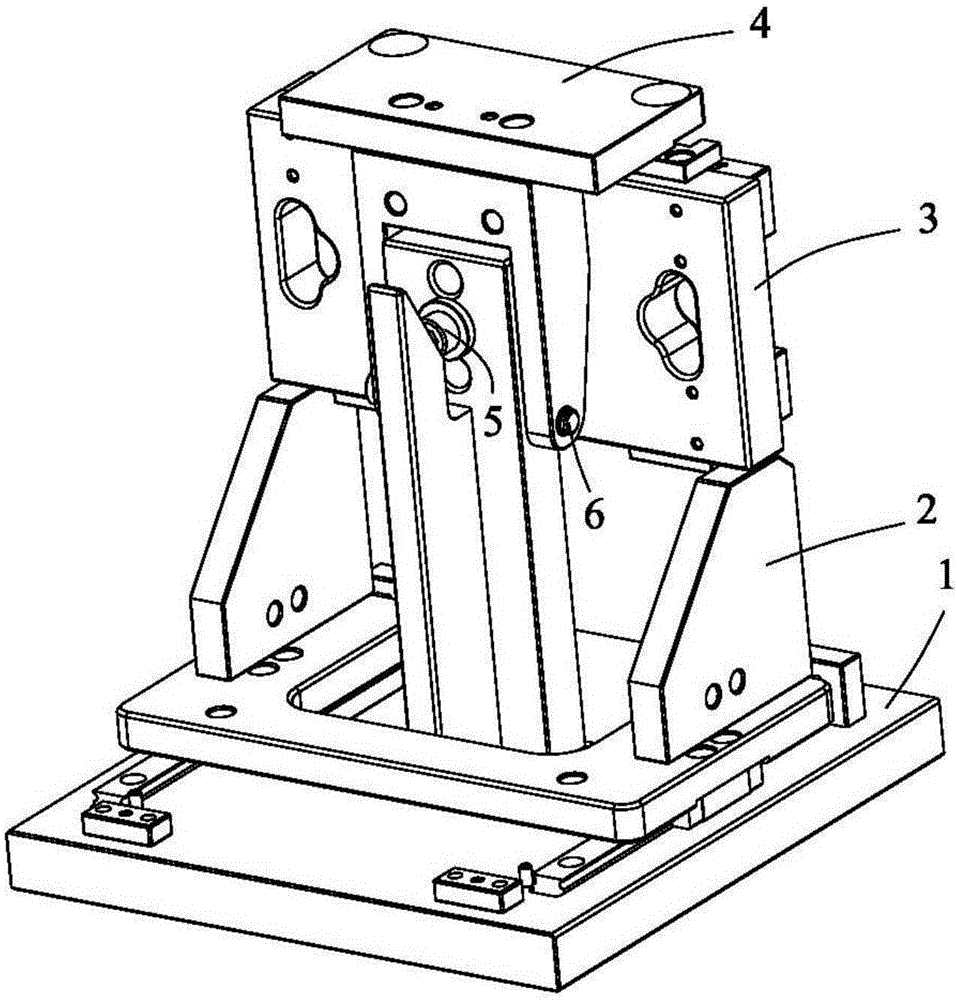

[0034] The jig for two-way side locking or removing screws of the present invention, please refer to figure 2 with image 3 As shown, it includes: a base part 1, a stop part 2 that is slidably fixed on the base part 1, a turning part 3 that is rotatably fixed on the base part 1 and used to fix the product 100, and rotatably fixed on the base part 1 And the rotating part 4 used for screw locking the product 100 or when removing the screw from the product 100 plays a positioning role, the axially connecting rotating part 2 to the first rotating shaft part 5 on the base part 1, and the axially connecting rotating part 4 to the second swivel shaft part 6 on the base part 1. Wherein, the flipping part 3 rotates 180° with the product 100 , and the other side of the product 100 can be screwed or removed from the other side of the product 100 .

[0035] see ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com