Automatic boxing production line

An automatic packing and production line technology, applied in packaging, bottle packaging, transportation and packaging, etc., can solve the problems of high labor intensity, low manual operation efficiency, physical fatigue, etc., and achieve the effect of saving working hours and human resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

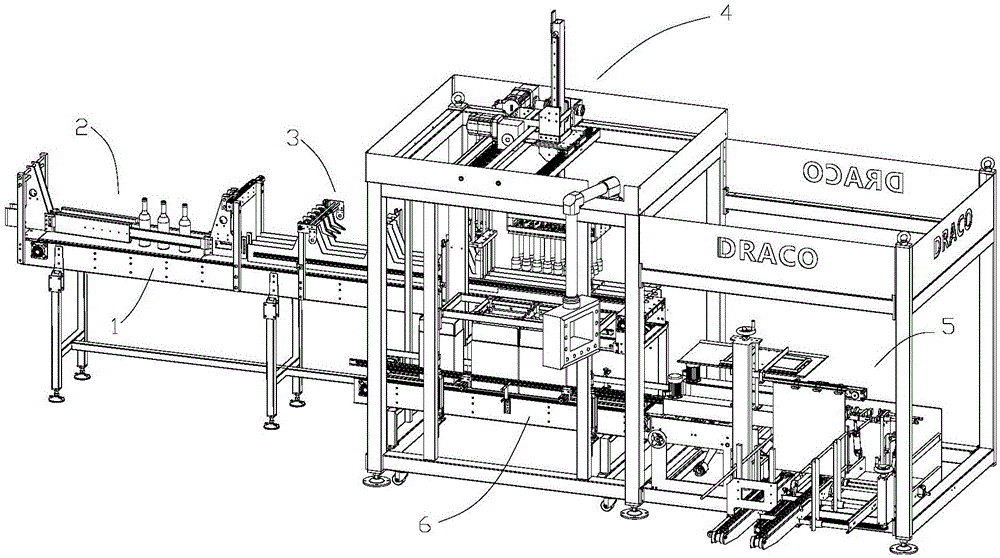

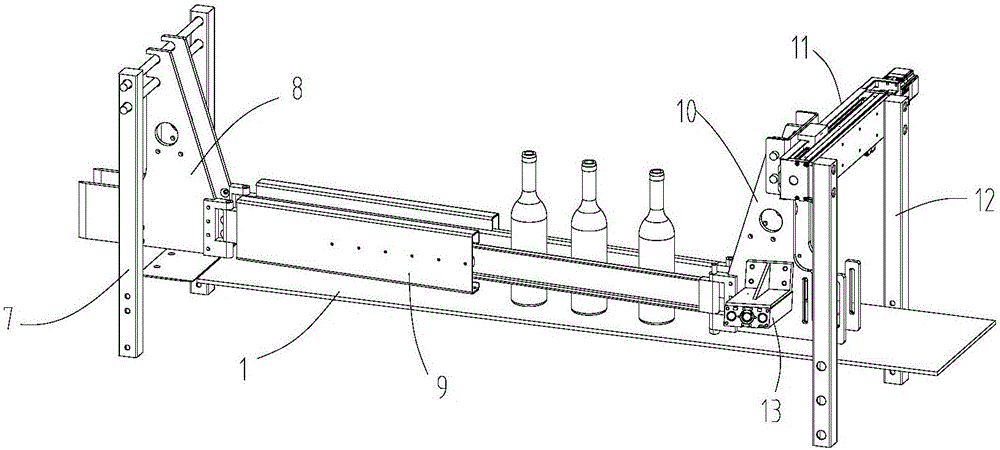

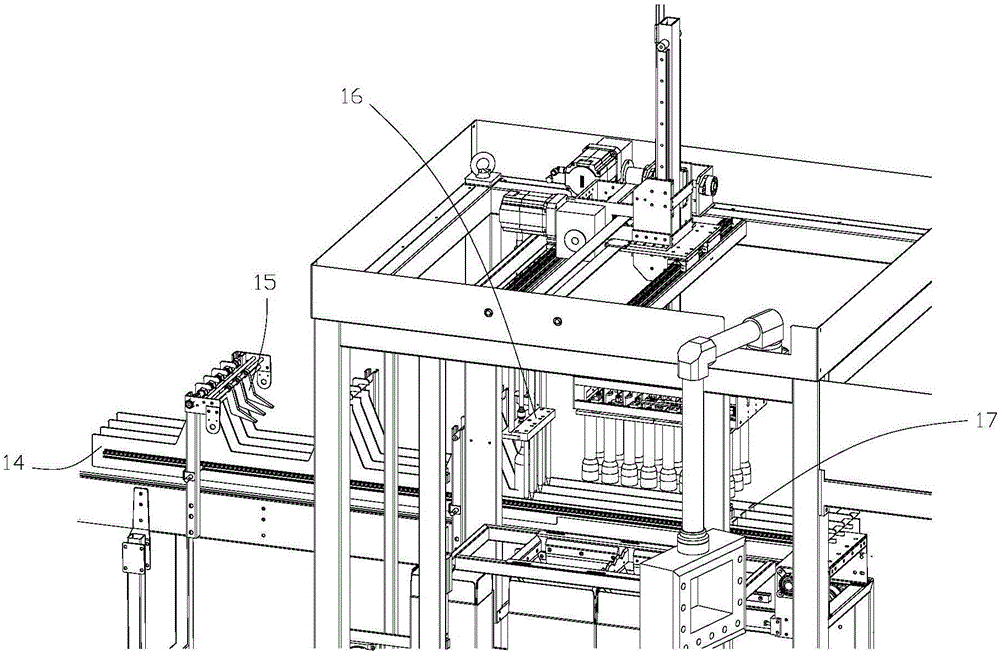

[0045] see figure 1 , this embodiment discloses an automatic packing production line, including a main conveying device 1, a conveying lane divider 2, a sorting channel 3, a packing device 4, a box forming device 5 and an auxiliary conveying device 6; the conveying lane divider 2 It is located on the main conveying device 1 and is located at the entrance of the main conveying device 1; the sorting passage 3 is connected to the exit of the conveying lane divider 2; the packing device 4 is arranged on the sorting passage 3, and the packing device 4 The output end is arranged at the outlet of the auxiliary conveying device 6 ; the box forming device 5 is connected with the inlet of the auxiliary conveying device 6 .

[0046] The main conveying device 1 is used to convey the manufactured finished goods forward, and the auxiliary conveying device 6 is used to convey the boxes to complete the boxing action. The main conveying device 1 and the auxiliary conveying device 6 can general...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com