A large transformer coil placement frame

A technology for transformer coils and placement racks, applied in the field of transformer manufacturing, can solve the problems of cumbersome moving in and out, unfavorable coil placement stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

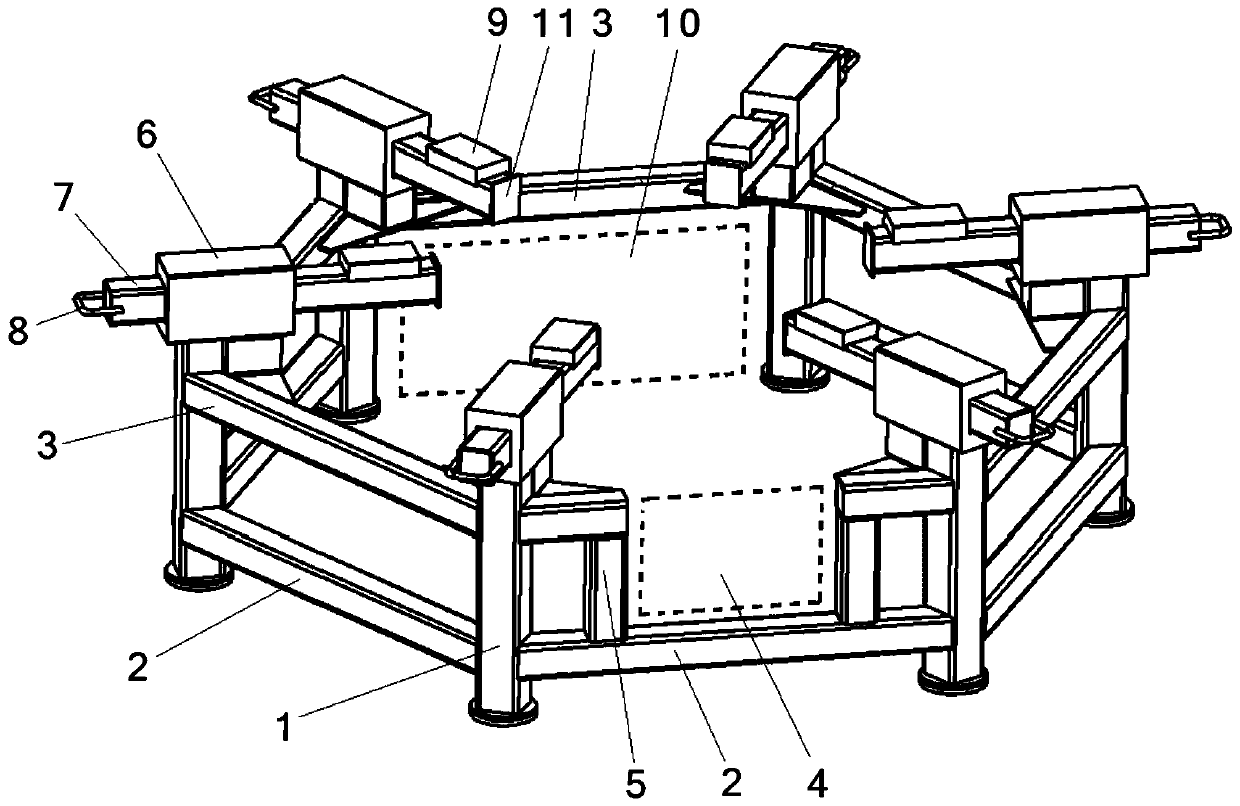

[0012] Such as figure 1 As shown, a large-scale transformer coil placement frame is formed by arranging the six vertices of six legs 1 in a regular hexagon; the two legs 1 on the front are fixedly connected by the lower beam 2 and are on the lower beam 2. A pair of uprights 5 are arranged to enclose the coil heading area 4; the respective two legs 1 of the left front side, left rear side, right front side and right rear side are fixedly connected by the lower cross beam 2 and the upper cross beam 3; the two rear legs 1 is fixedly connected by the upper beam 3 and encloses the inspection entrance 10; each leg 1 is fixed with a telescopic bracket fixing seat 6; the telescopic bracket fixing seat 6 points inward to the center of the regular hexagon; the telescopic bracket A telescopic bracket 7 passes through the fixing seat 6; the outward end of the telescopic bracket 7 is provided with a handle 8, and the upper surface of the inward end is provided with a nylon sheath 9; the six...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com