Anti-falling device of electric coil classification shelf

A technology for placing racks and electric coils, which is applied to tool storage devices, manufacturing tools and other directions, can solve the problem of easy falling of electric coils, etc., and achieves the effect of saving time, strong adaptability and improving work efficiency when accessing wires.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

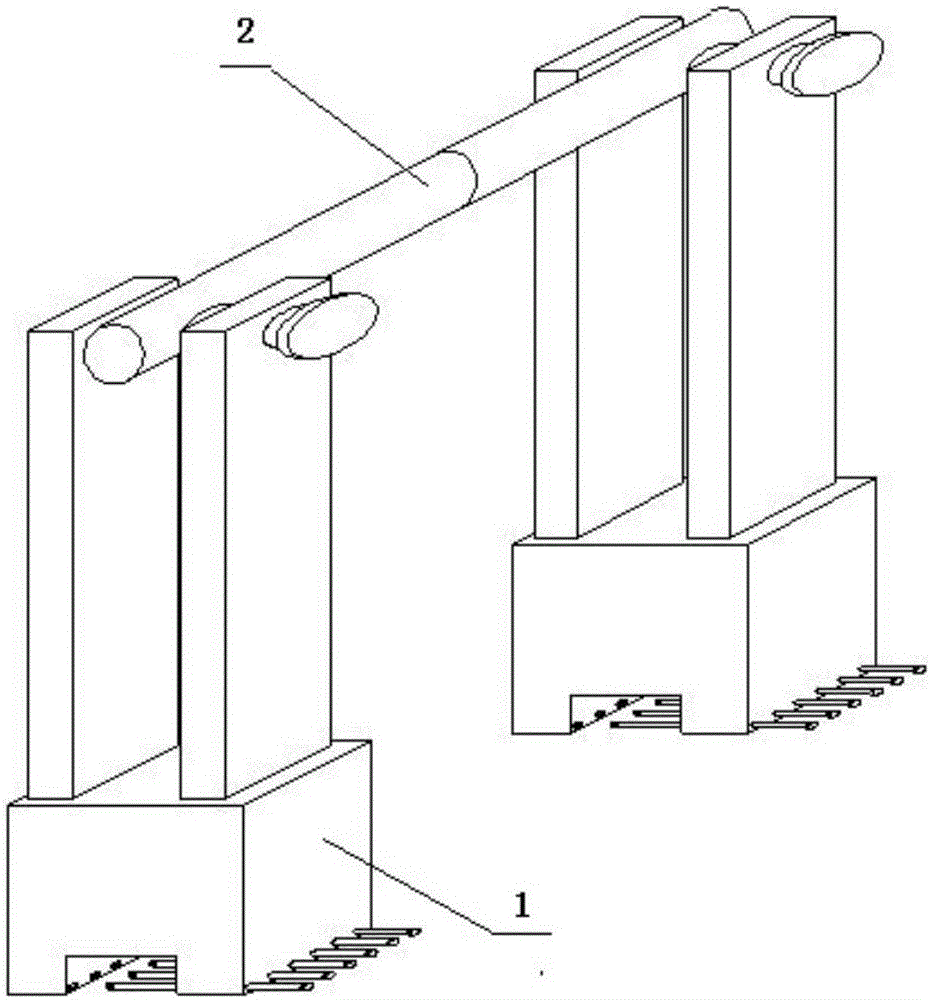

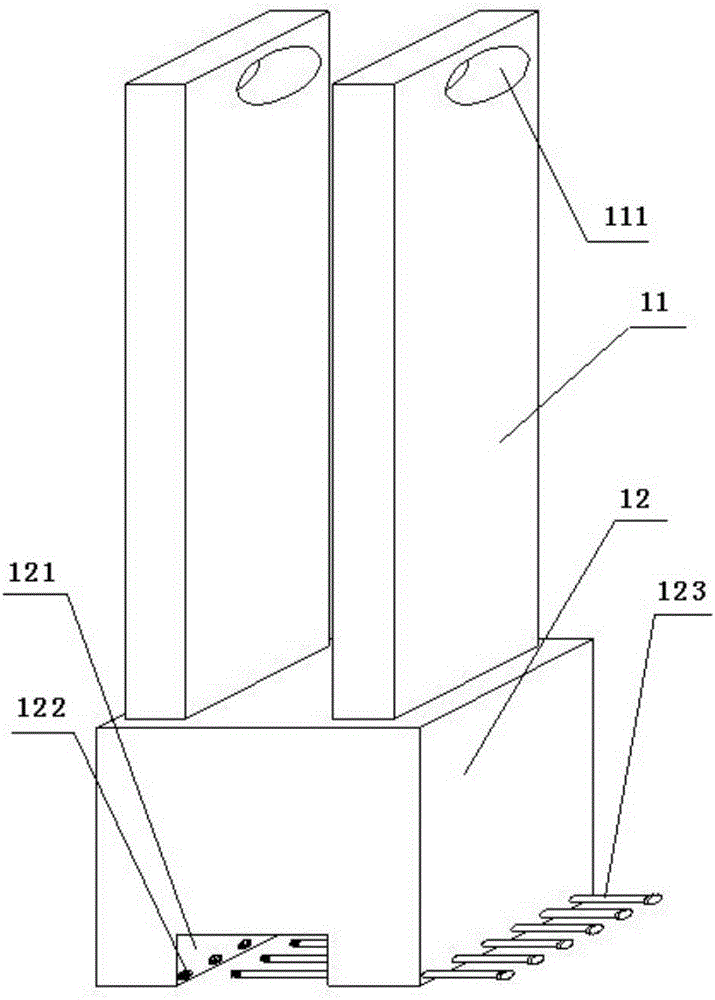

[0021] Such as figure 1 , figure 2 As shown, a kind of anti-falling device of the electric coil sorting rack is installed on the vertical bar of the electric coil sorting rack, and is composed of two sliding frames 1 and telescopic devices 2, and the sliding frame 1 is composed of sliding Rod 11 and square sliding block 12 are formed, and described sliding block 12 is provided with chute 121, and described chute 121 is sleeved outside vertical bar, and chute 121 side is provided with some smooth through holes, and the other side of chute 121 Corresponding positions on one side are provided with several threaded holes 122, and the smooth through holes correspond to the threaded holes 122 one by one, and a connecting rod 123 is arranged in the smooth through hole, and the length of the connecting rod 123 is greater than that from the bottom of the threaded hole 122 to the smooth through hole. The distance outside the hole, the end of the connecting rod 123 is provided with an ...

Embodiment 2

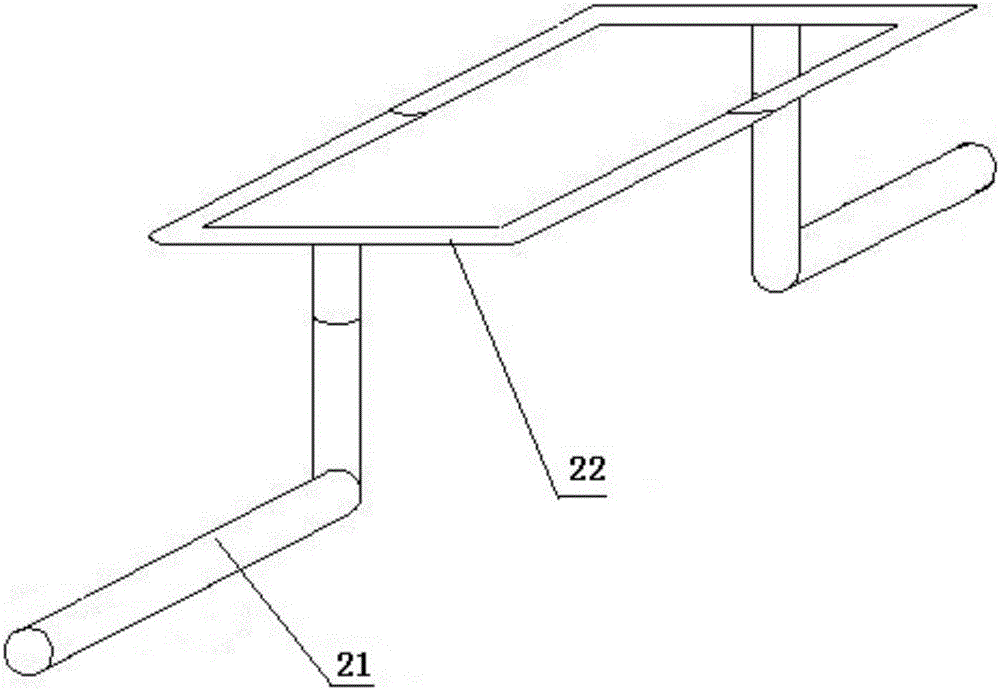

[0028] Such as image 3 As shown, it is further optimized on the basis of the anti-drop device of a kind of electric coil classification and placement rack described in Embodiment 1. The telescopic device 2 is composed of two L-shaped telescopic rods 21 and a telescopic frame 22. Two L-shaped The non-telescopic one-side ends of the L-shaped telescopic rods 21 are all fixed on the slide rod 11, and the telescopic one-side ends of the two L-shaped telescopic rods 21 are respectively connected to the two ends of the telescopic frame 22, and the plane where the telescopic frame 22 is located Parallel to the plane where the bottom surface or top surface of the sliding block 12 is located.

[0029] The L-shaped telescopic rod 21 set in this embodiment can realize the expansion and contraction in the vertical direction, and the expansion and contraction frame 22 can realize the expansion and contraction in the horizontal direction, so this embodiment can not only fully adapt to the d...

Embodiment 3

[0031] It is further optimized on the basis of the anti-falling device of a kind of electric coil sorting rack described in embodiment 1 or 2, the sliding rod 11 and the sliding block 12 are movably connected, and the setting of this embodiment is convenient for disassembly and installation .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com