Closed die forging method of GH4169 stator blade

A GH4169, stator blade technology, applied in the field of forging, can solve the problems of high manufacturing cost of forging blades, not suitable for small batches, complex process, etc., to shorten the production cycle, ensure the performance of parts, and simplify the process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

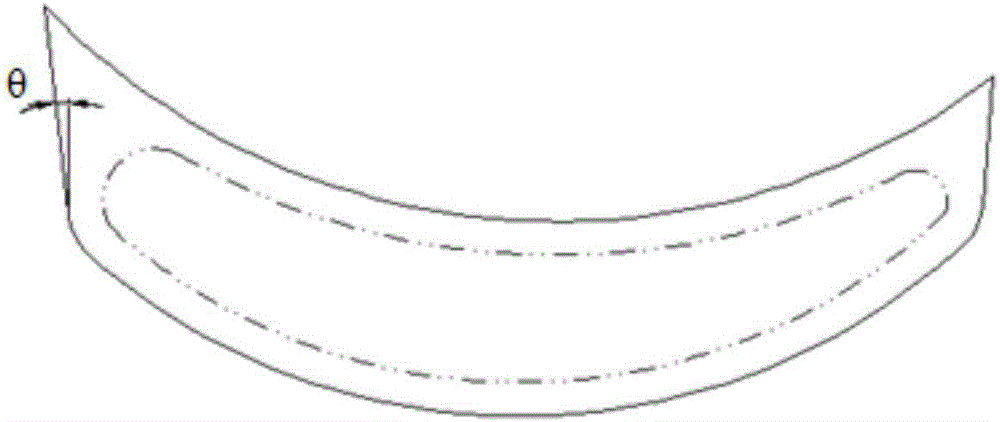

[0038] 1. Forging design: according to figure 1 , the direction of blade thickness: according to the outer normal direction of the blade pot and blade back of the stator blade parts, add a margin of 3mm to obtain the blade pot and blade back of the forging; blade chord width direction: according to the inlet and outlet of the stator blade parts After each edge is extended 3mm outward, draw a tangent line from the blade back direction to the blade pot direction on the obtained arc at an angle of 5°, and extend and intersect with the forging blade pot surface to obtain the cross-sectional shape of the stator blade forging; the blade length direction : According to the length of the stator blade part, both ends extend 4mm outward to obtain the blade forging;

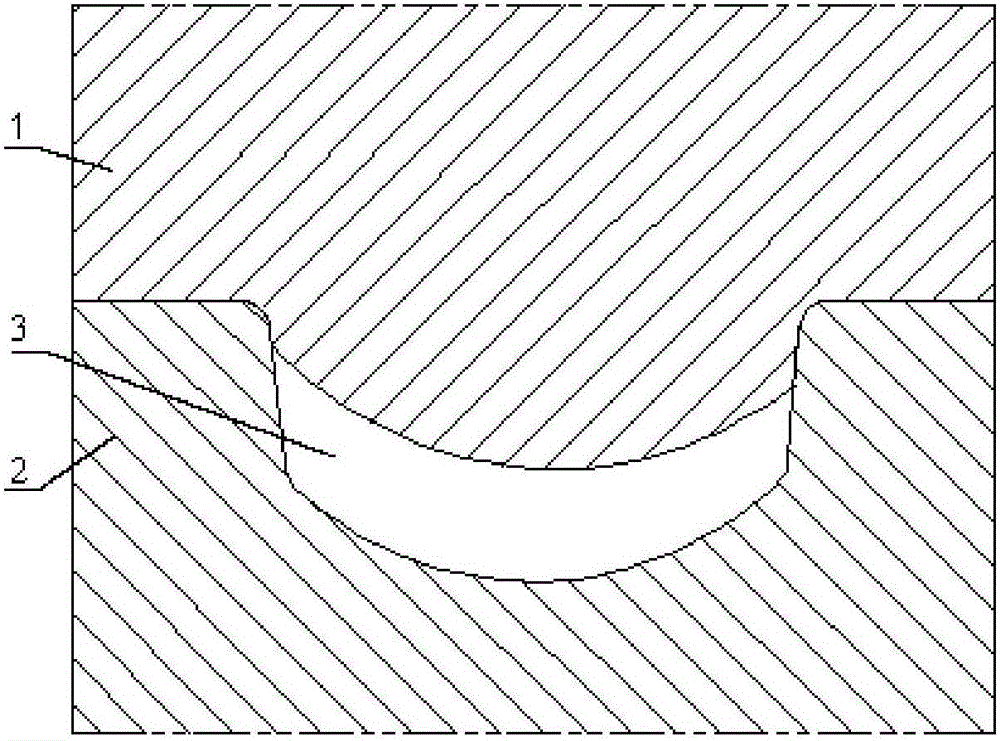

[0039]2. Closed mold design: including upper mold and lower mold, closed mold cavity part: the upper mold cavity is designed according to the surface of the forging blade basin, and protrudes from the mold base level by 15m...

Embodiment 2

[0046] 1. The forging design is the same as above;

[0047] 2. Closed mold design: including upper mold and lower mold, closed mold cavity part: the upper mold cavity is designed according to the surface of the forging leaf basin, and protrudes 20mm from the base level of the mold; the lower mold cavity is designed according to the profile of the forging leaf back, And recess the lower mold reference plane by 20mm, and the convex height of the upper mold should be consistent with the concave height of the lower mold; the side wall of the upper mold convex and the lower mold concave should be designed according to 5°, and this angle is the draft slope; The bosses of the upper mold and the side walls of the grooves of the lower mold are fitted together, which can not only control the displacement of the forging, but also prevent the generation of burrs to form a closed mold; the cavity of the upper and lower molds is in the length direction, and the length of the forging is added...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com