A kind of preparation method of high-strength slide rail

A high-strength, slide rail technology, applied in the field of preparation of high-strength slide rails, can solve the problems of slow production speed and too simple operation steps, and achieve the effects of convenient positioning, fast limit and convenient limit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

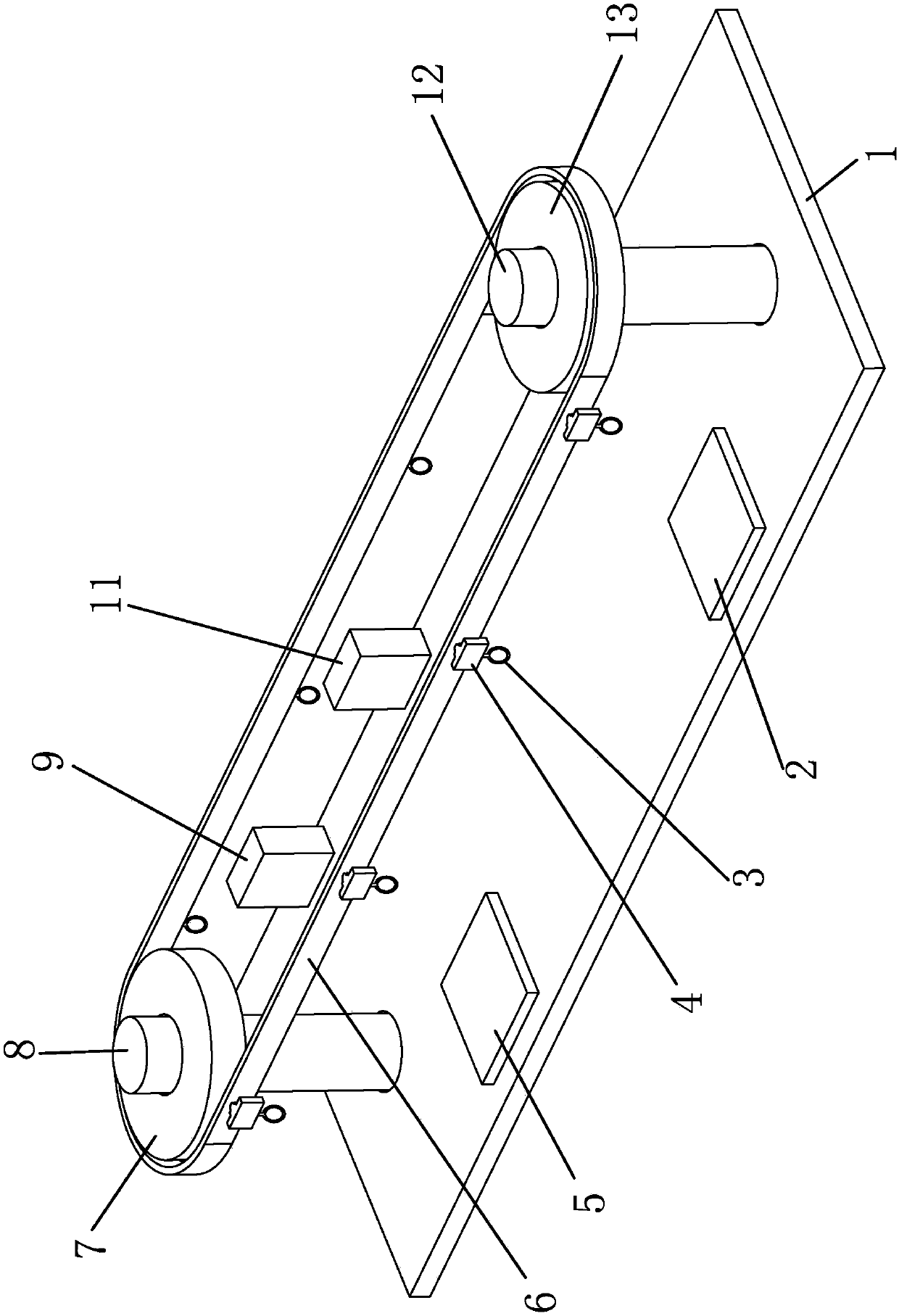

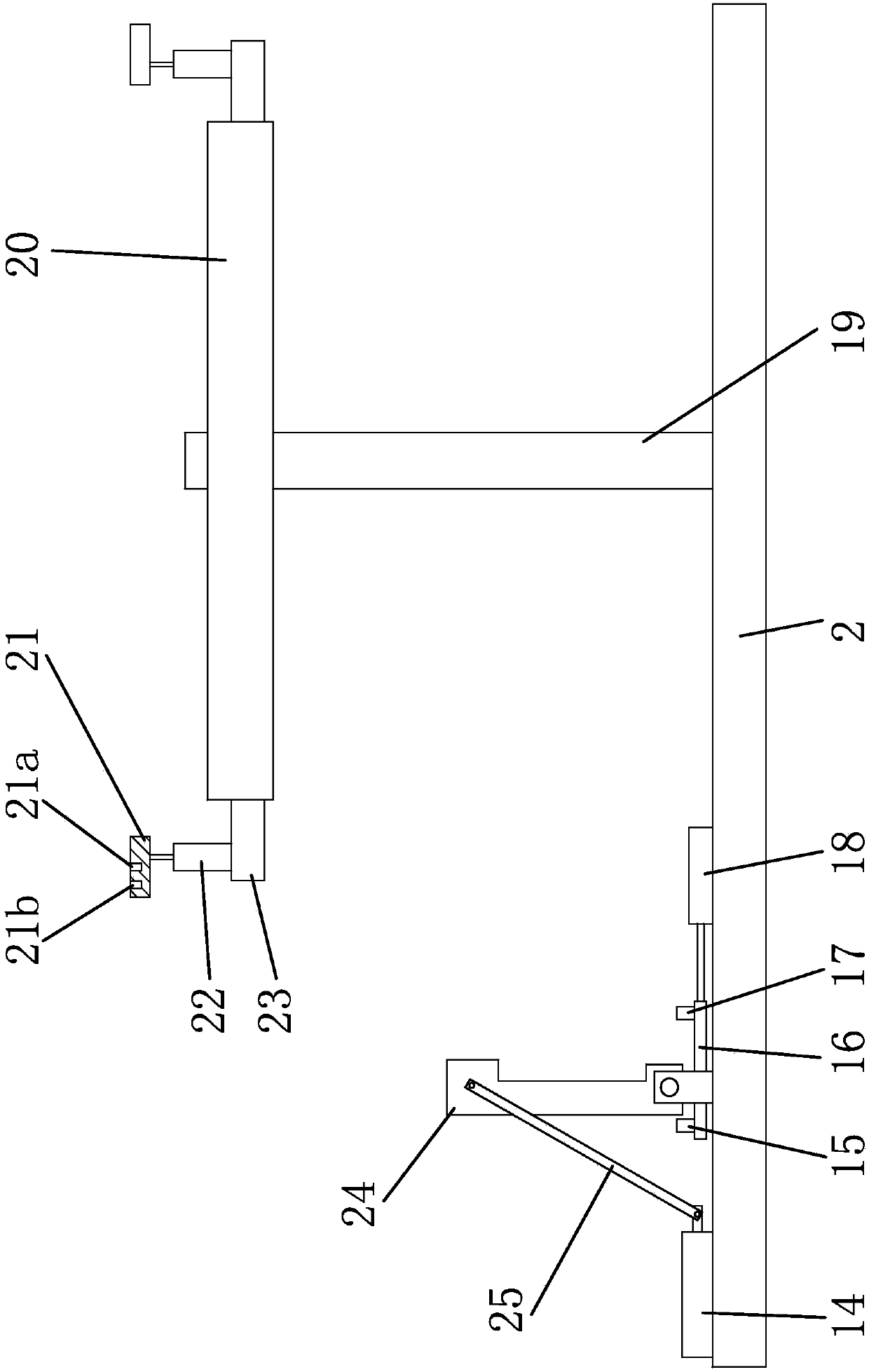

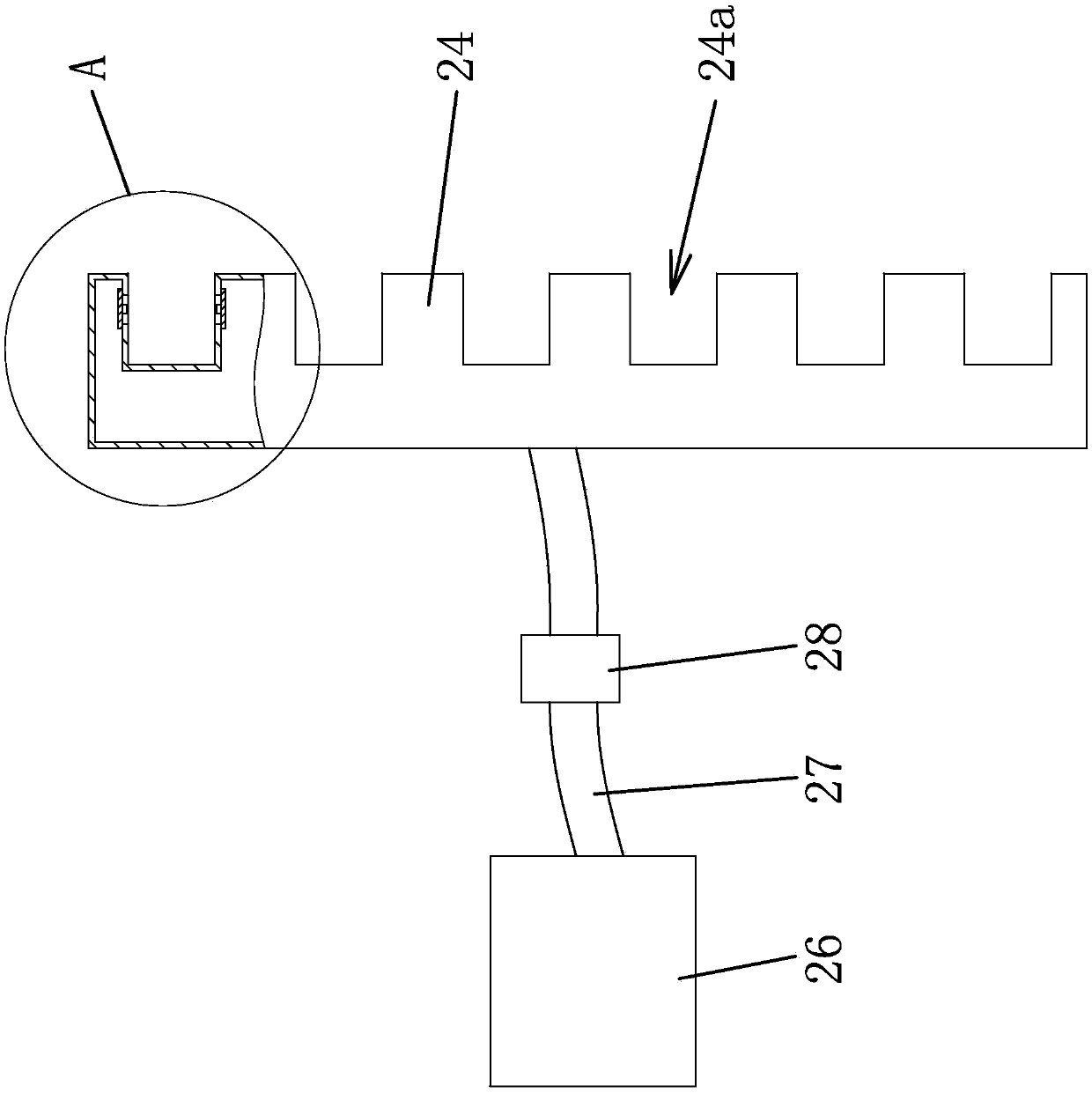

[0055] The following are specific embodiments of the present invention in conjunction with the accompanying drawings to further describe the technical solutions of the present invention, but the present invention is not limited to these embodiments.

[0056] The preparation method of the high-strength slide rail includes the following steps:

[0057] a. Purchasing: outsourcing the required gaskets and rivets and inspecting them;

[0058] b. Injection molding: Inject the plastic particles through an injection molding machine to obtain a pulley;

[0059] c. Stamping: cold-stamping the cold-rolled metal sheet to obtain the inner rail body and the outer rail body. The thickness of the cold-rolled metal sheet is 1.2-1.6mm. In this embodiment, the thickness of the cold-rolled metal sheet is 1.4mm;

[0060] d. Spraying: spray powder coating on the punched inner rail body and outer rail body through the spraying system. The spraying thickness is 0.1-0.3mm. The powder coating formula is based o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com