Tilting mechanism of rotor craft

A technology of a rotorcraft and a tilting mechanism, which is applied in the field of aircraft and can solve the problems of limited take-off weight and complex pendulum environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

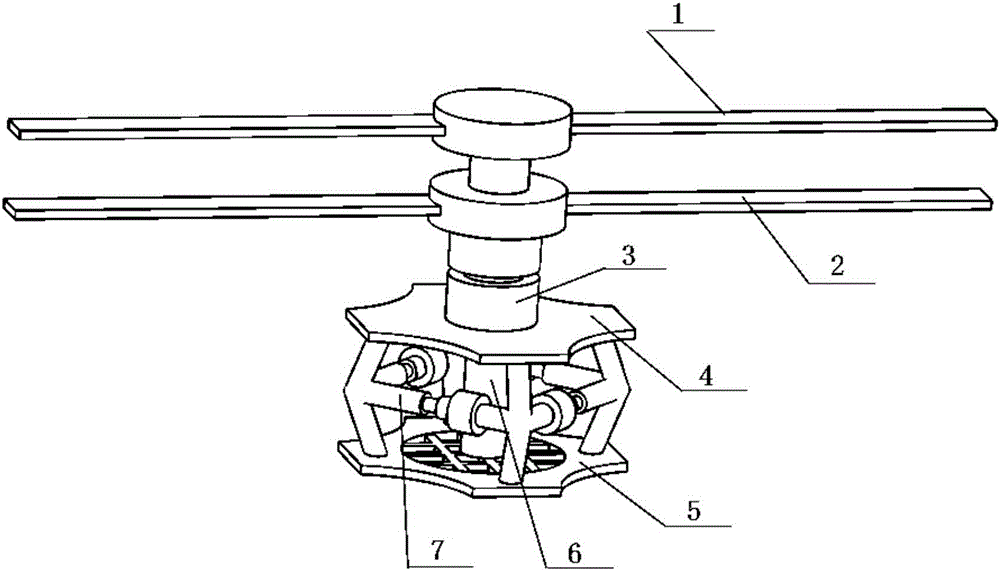

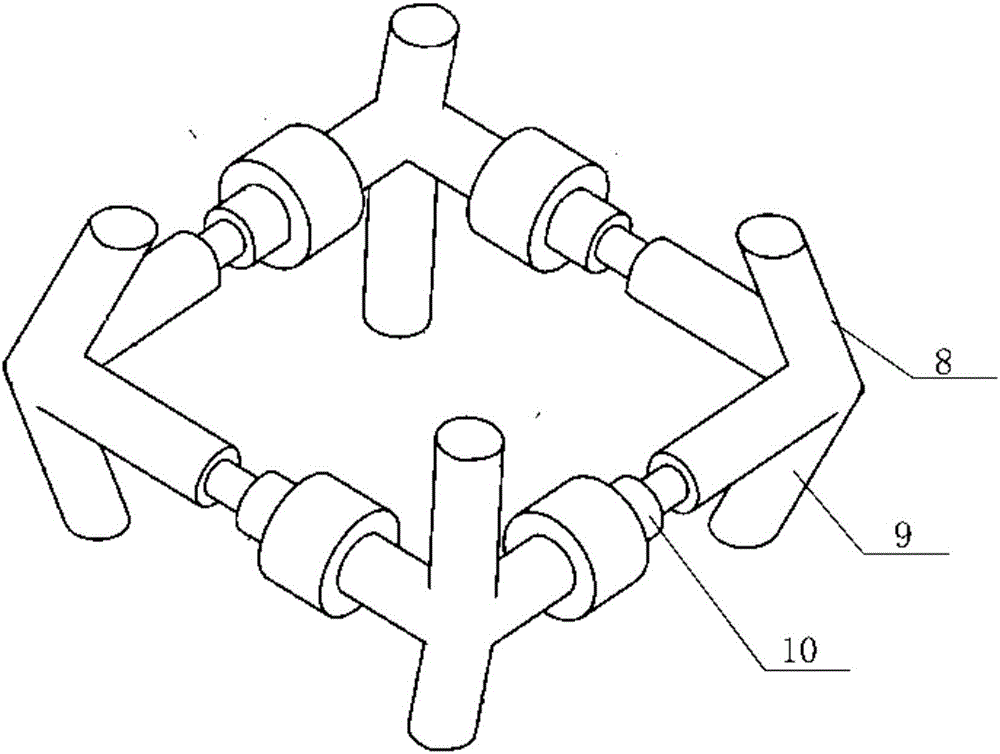

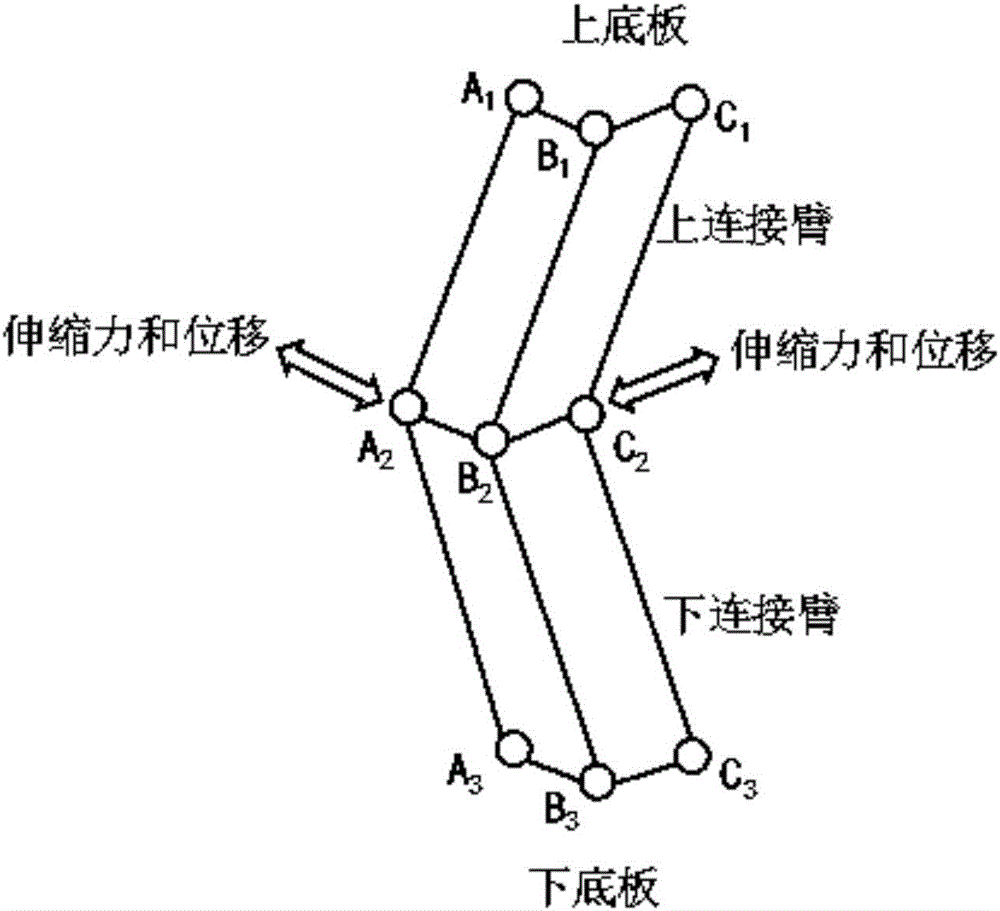

[0012] In a basic embodiment, the present disclosure provides a rotorcraft tilting mechanism, wherein: the tilting mechanism includes a fuselage, a first motor, and a rotor, wherein: the rotor is connected to the first motor, and the first motor It is arranged on the fuselage; the fuselage includes an upper base plate, a lower base plate, a support rod, and a telescopic component, wherein: the support rod is arranged between the upper base plate and the lower base plate, and is used to support and connect the upper base plate and the lower base plate; The telescopic component can change the distance between the upper base plate and the lower base plate, thereby realizing the change of the tilting direction of the aircraft.

[0013] In this embodiment, the distance between the upper base plate and the lower base plate can be changed by using a relatively small force through the telescopic parts, and the attitude of the aircraft can be changed to realize the tilting of the aircra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com