Tunnel waterproof and drainage system and its construction method

A technology for waterproofing and drainage and tunneling, which is applied in drainage, tunnels, tunnel linings, etc., can solve the problems of easy damage, weak welding, and damage to waterproof boards, and achieves good long-term service performance, convenient operation and maintenance, and easy operation and maintenance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

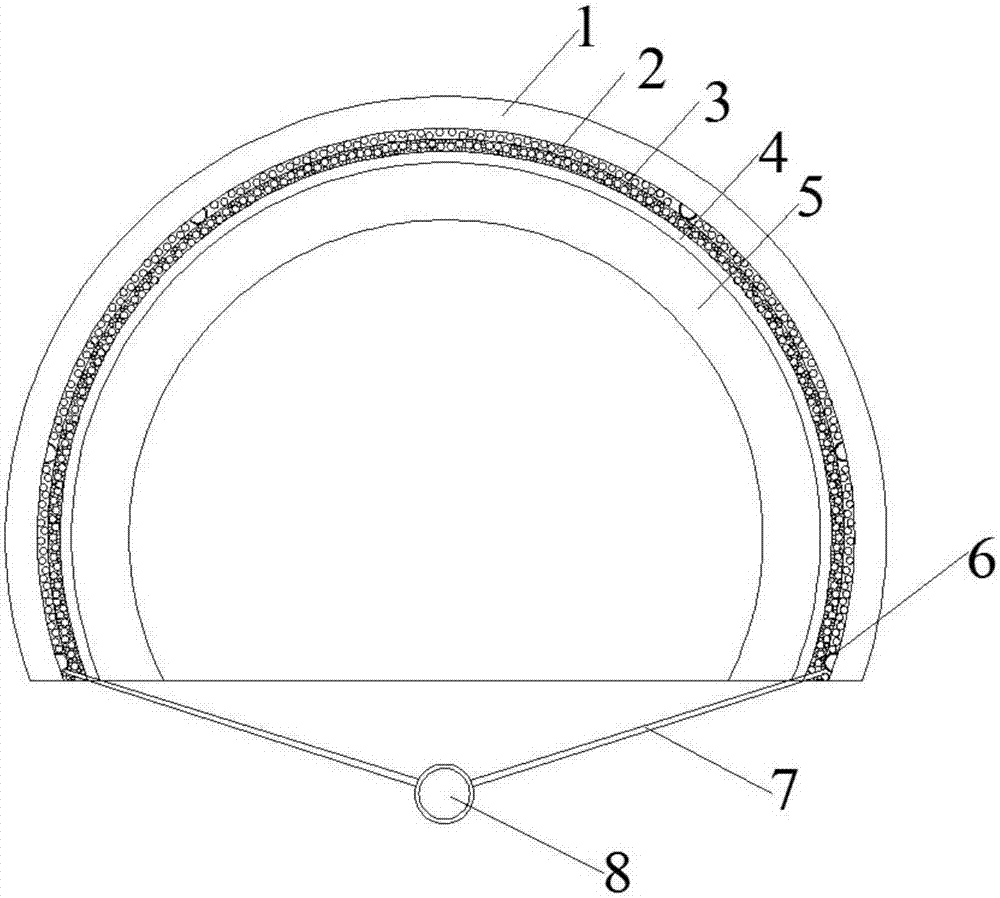

[0032] The tunnel waterproof and drainage system of this embodiment is as follows: figure 1 As shown, it includes primary support 1, drainage layer 2, transition layer 3, waterproof layer 4, and secondary lining 5 arranged in sequence in the tunnel, as well as horizontal drainage pipe 7 and central drainage pipe 8 at the bottom of the tunnel.

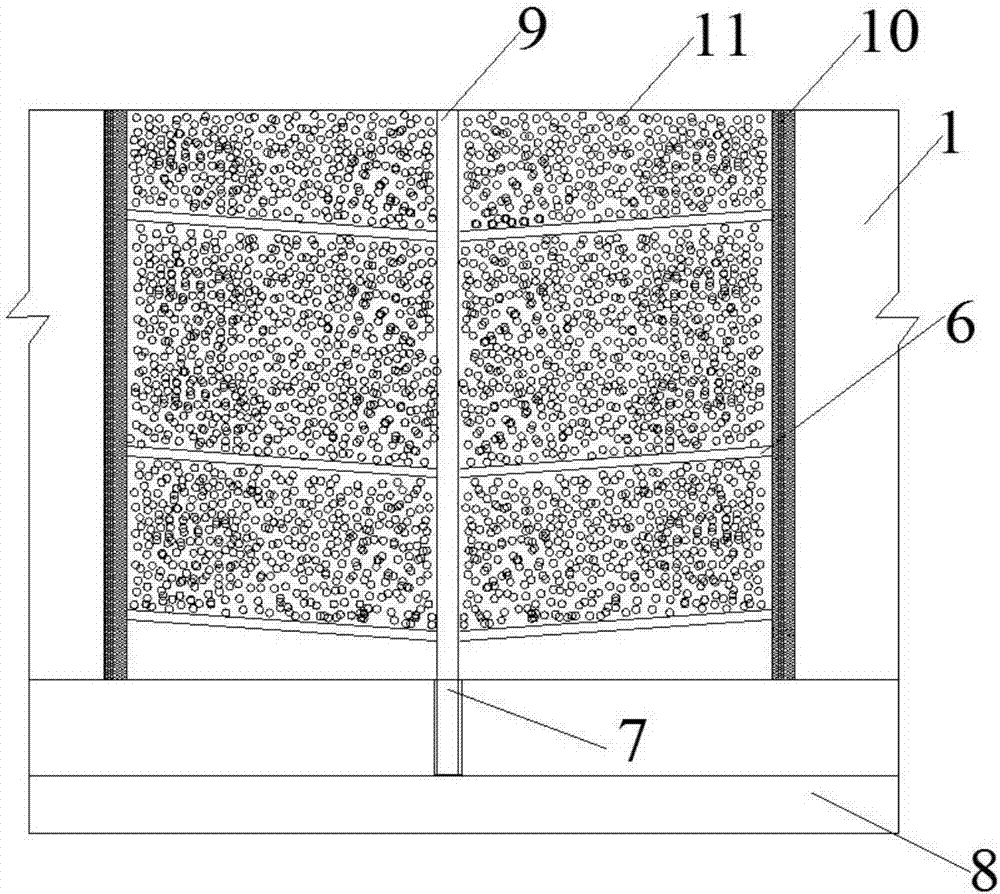

[0033] Such as figure 2 As shown, the interior of the drainage layer 2 contains a longitudinal drainage pipe 6 , a circumferential drainage pipe 9 , a water stop strip 10 and a permeable shotcrete 11 . The vertical drainage pipe 6 is connected to the circumferential drainage pipe 9 and the water stop strip 10 , and the horizontal drainage pipe 7 is connected to the circumferential drainage pipe 9 and the central drainage pipe 8 .

[0034] The construction implementation steps of the above structure are as follows:

[0035] ①Clean the initial support surface or surrounding rock surface of the tunnel, and lay waterstop strips 10, circu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com