Drop weight impact test device for secondary loading

A technology of impact test and secondary loading, which is applied in the direction of measuring devices, fuel testing, material inspection products, etc., can solve the problems of inability to effectively evaluate the stability of explosives, large amount of explosives, and failure to meet the requirements of explosive safety performance evaluation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with examples, but the embodiments of the present invention are not limited thereto.

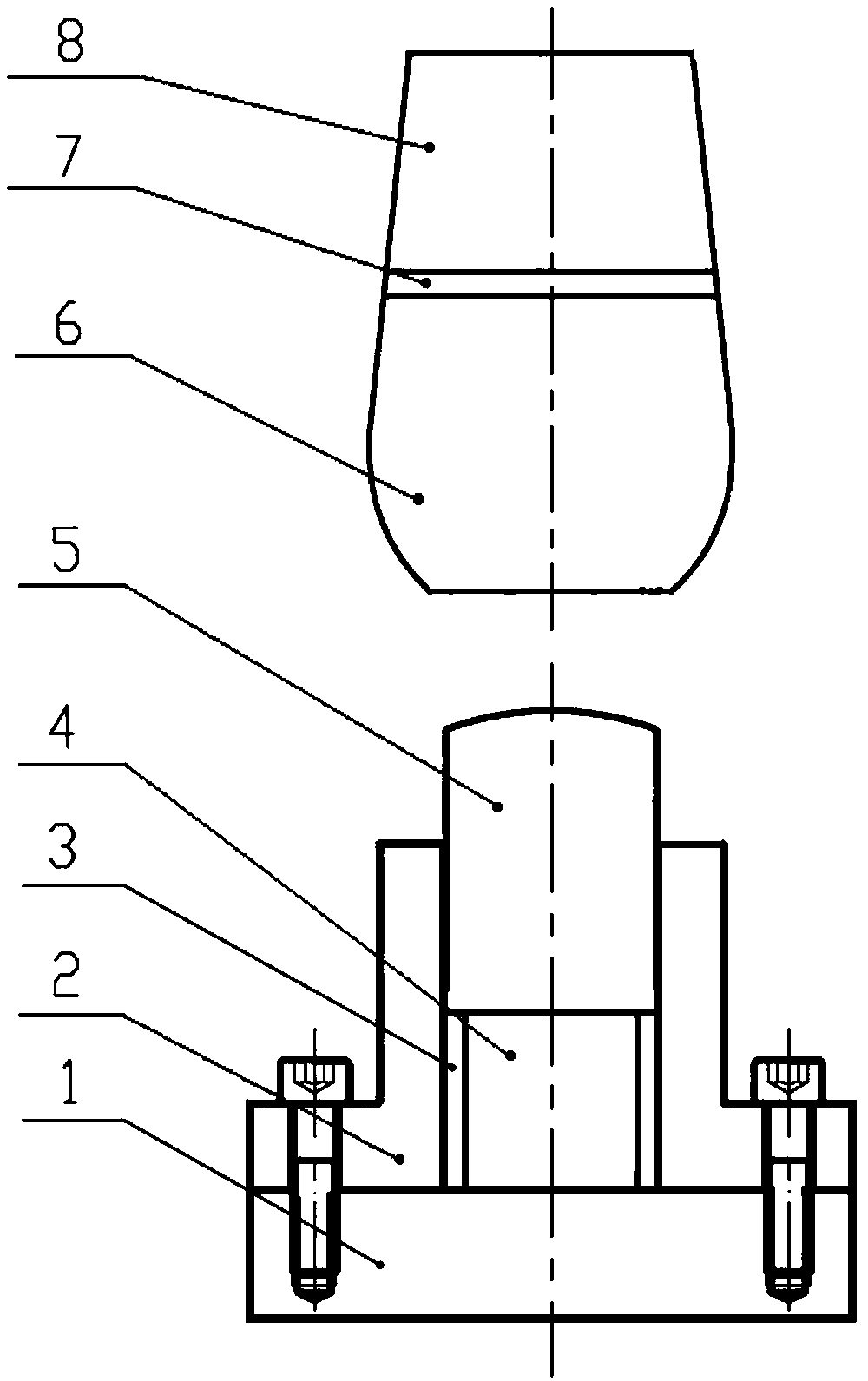

[0022] Such as figure 1 as shown, figure 1 It shows a schematic structural diagram of a drop weight impact test device for realizing secondary loading according to an embodiment of the present invention. A drop weight impact test device for realizing secondary loading includes a base 1, a sample cover 2, An inert ring 3, an explosive cavity 4, a peg 5 and a drop weight, the sample set 2 is arranged on the base 1, the inert ring 3 is set inside the sample set 2, and the lower end of the peg 5 is located In the inert ring 3 and the peg 5 is located above the sample set 2, an explosive cavity 4 for placing explosives is formed between the sample set 2 and the peg 5, and above the peg 5 A drop hammer is set, and the drop hammer is composed of a primary hammer body 6, a buffer layer 7 and a secondary hammer bo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com