Mobile phone shell processing technology, mobile phone shell and mobile phone

A processing technology and mobile phone shell technology, which is applied in the direction of telephone structure, antenna support/mounting device, pre-treatment surface, etc., can solve the problems of weak sense of metal integration, poor metal feeling of mobile phone shell, high processing cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

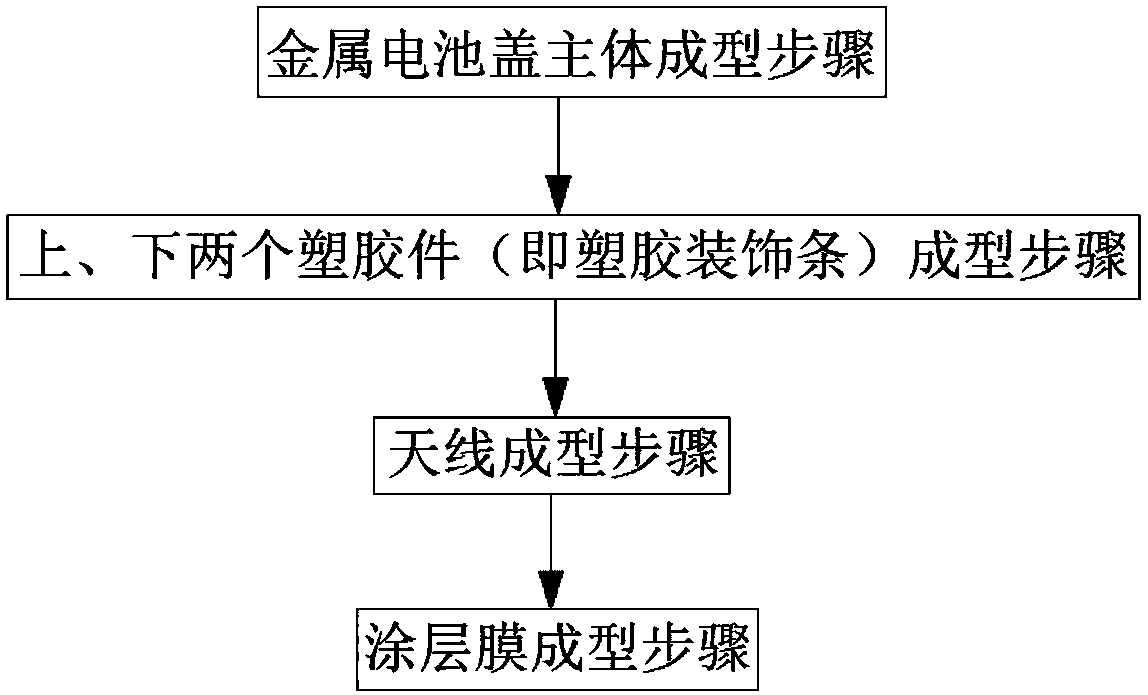

[0045] refer to Figure 1 to Figure 8 , provide a kind of mobile phone casing processing technology in the present embodiment, comprise the steps:

[0046] The forming step of the main body of the metal battery cover is to extrude the metal blank and perform anodic oxidation surface treatment to form the main body 11 of the metal battery cover;

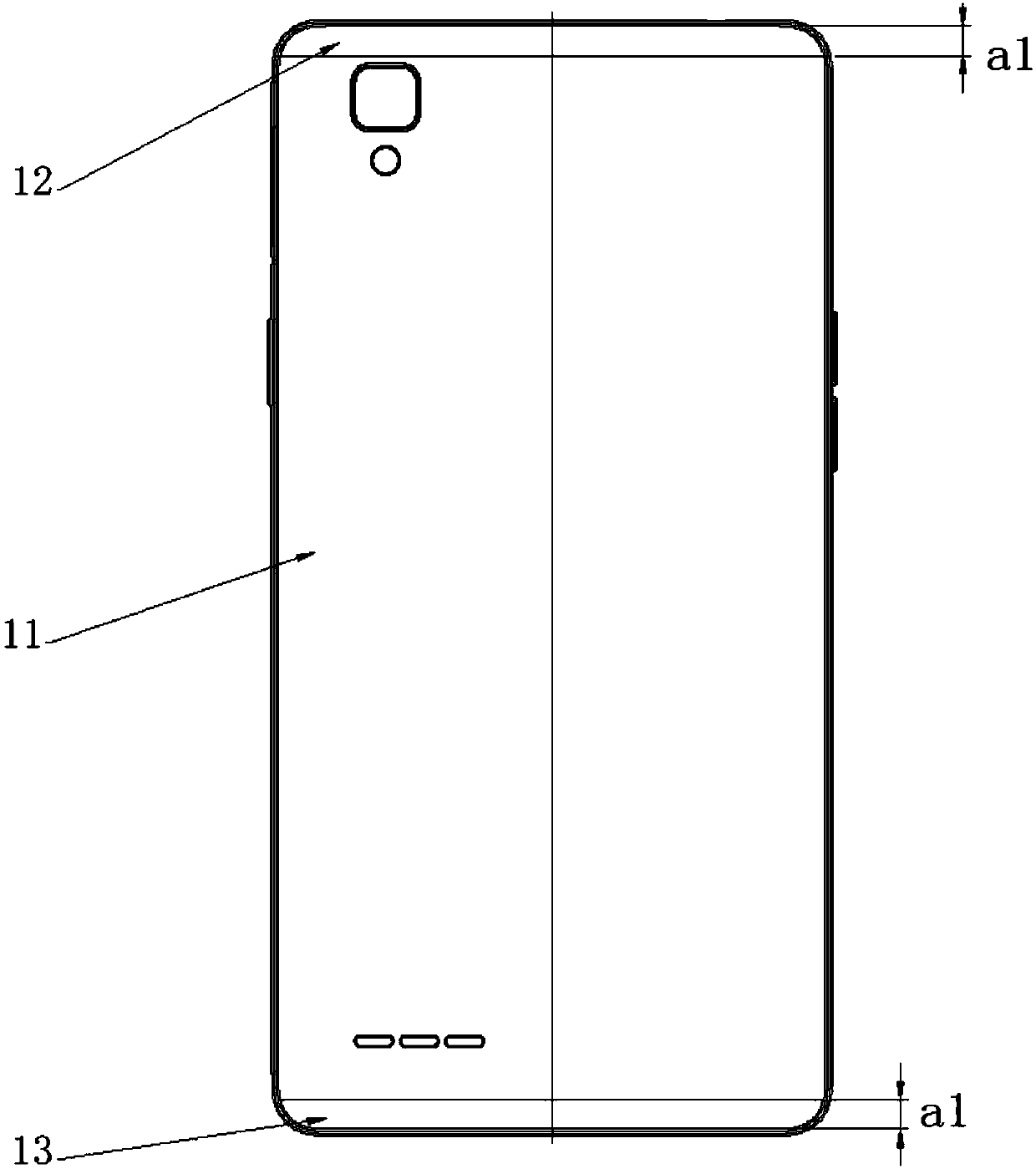

[0047] In the molding step of the upper and lower plastic parts (ie, plastic decorative strips), two plastic parts (ie, plastic decorative strips 12, 13) are formed by plastic injection molding, and the width a1 of the plastic parts (ie, plastic decorative strips 12, 13) is less than or equal to 4mm, in the figure, the upper plastic decorative strip is marked with "12", and the lower plastic decorative strip is marked with "13";

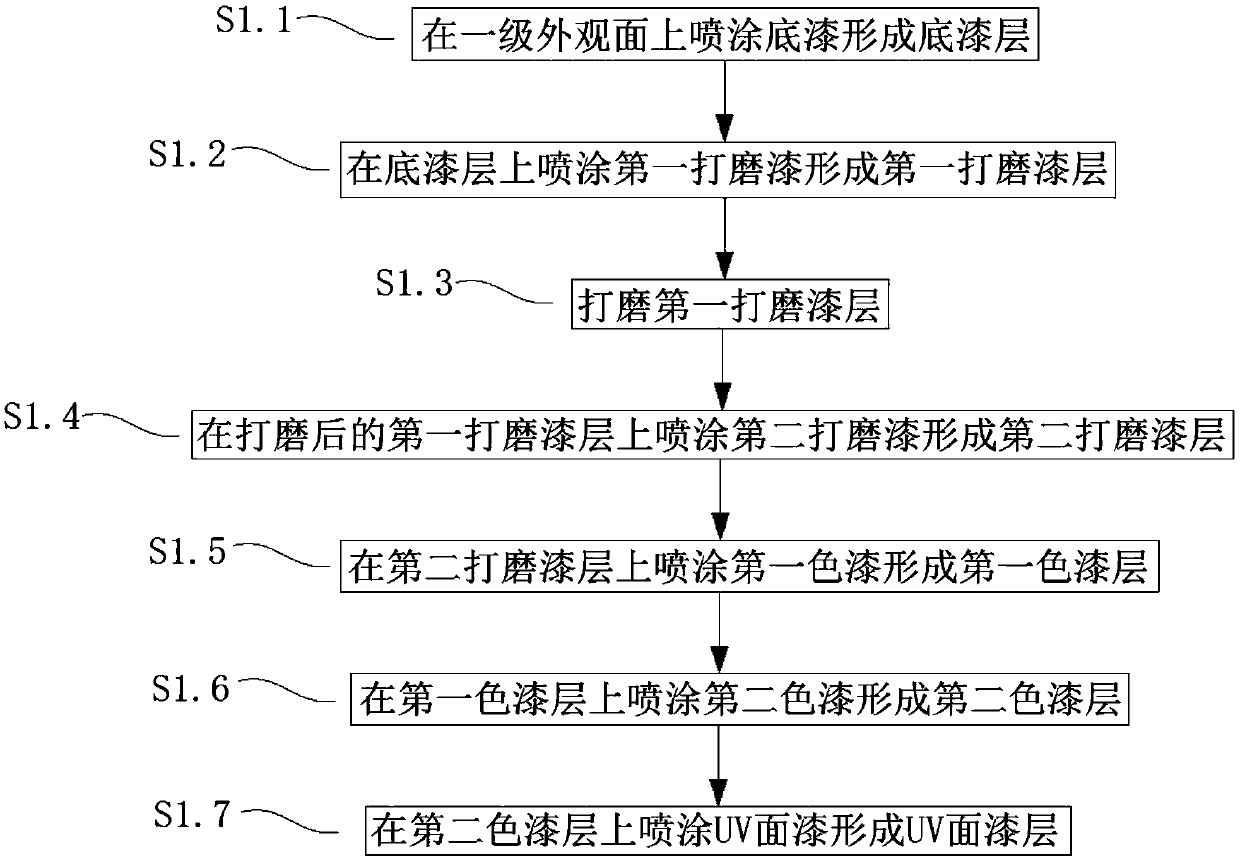

[0048] The antenna molding step is to form the antenna 14 (for example, a printed antenna) on the primary appearance surface of the plastic parts (i.e. the plastic decorative strips 12, 13), specifically, t...

Embodiment 2

[0061] Can continue to refer to Figure 3 to Figure 8 , In this embodiment, a mobile phone case is provided, which can be processed by the mobile phone case processing technology in Embodiment 1, and of course, can also be produced by other methods.

[0062]Specifically, the mobile phone case includes a metal battery cover main body 11 and two upper and lower plastic parts (namely, plastic decorative strips 12, 13). An antenna 14 and a coating film are provided on the primary appearance surface of the plastic part (i.e. the plastic decorative strip 12, 13), that is, the antenna 14 is molded on the top surface of the plastic part above (i.e. the plastic decorative strip 12, 13) and Antenna 14 is molded on the bottom surface of the plastic parts below (i.e. plastic decorative strips 12, 13), and the coating film covers antenna 14 and the area other than antenna 14 in the first-level appearance surface. Maximum thickness) is less than or equal to 13um. Specifically, in this embo...

Embodiment 3

[0072] refer to Figure 10 to Figure 17 In this embodiment, a mobile phone casing processing technology is provided. The difference from Embodiment 1 is that in this embodiment, the plastic part is a plastic middle frame 24, and the mobile phone casing also includes a metal battery back cover 21 and upper and lower plastic decorations. Articles 22, 23.

[0073] Specifically, the mobile phone casing processing technology of the present embodiment includes the following steps:

[0074] The metal battery back cover 21 forming step is to extrude the metal blank and perform anodic oxidation surface treatment to form the metal battery back cover 21;

[0075] The molding steps of the upper and lower plastic decorative strips are two plastic decorative strips 22 and 23 formed by plastic injection molding, and the width a2 of the plastic decorative strips 22 and 23 is less than or equal to 4mm;

[0076] Plastic parts (ie, plastic middle frame) molding step, injection molding of plast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com