Patents

Literature

45results about How to "Improve experience value" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

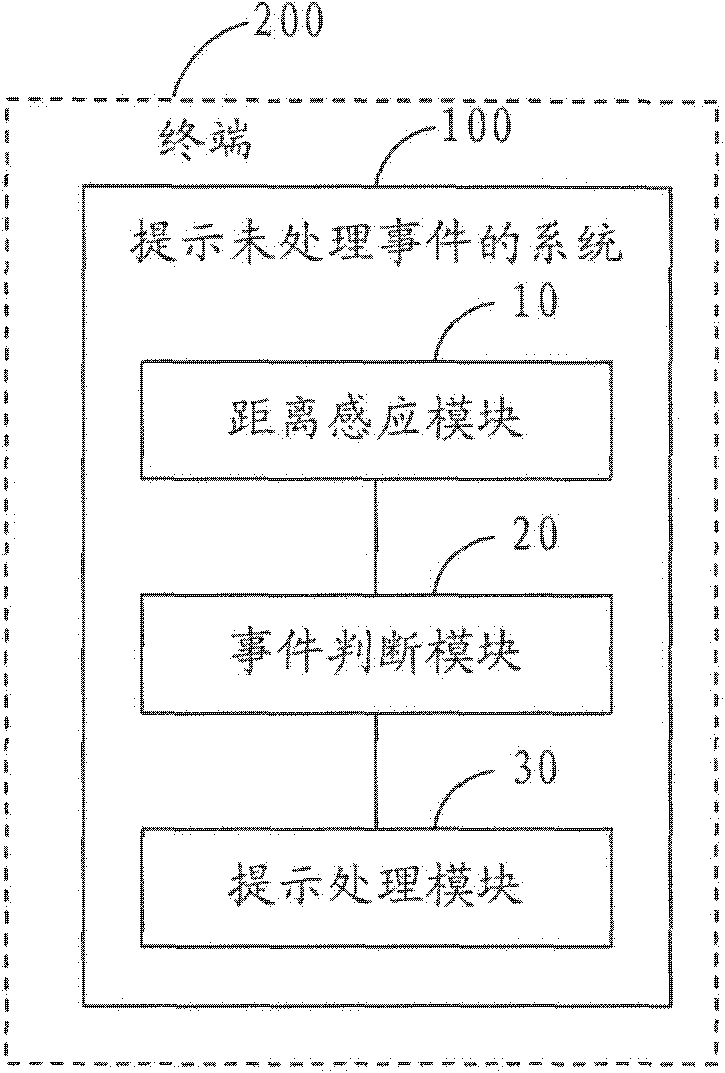

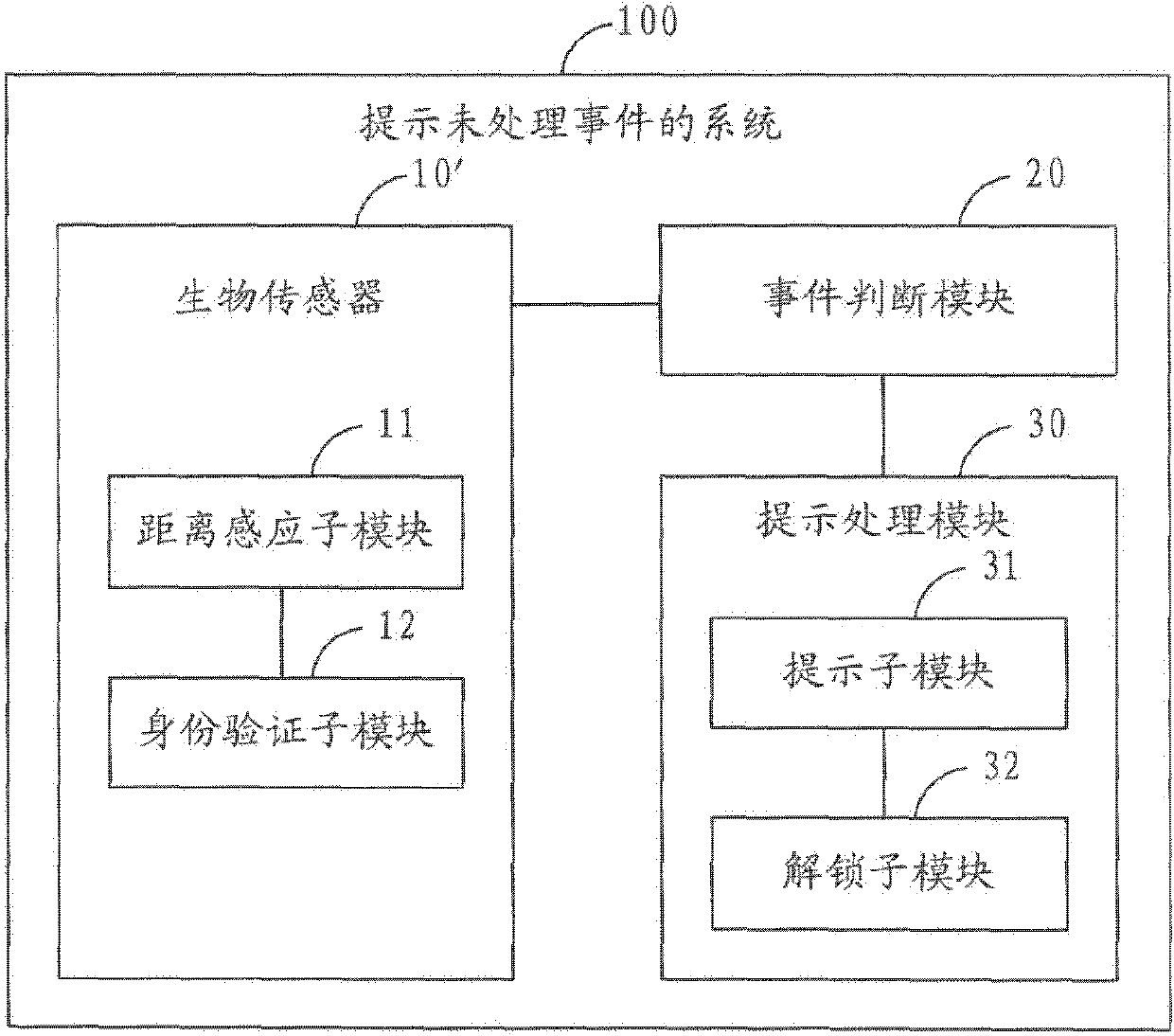

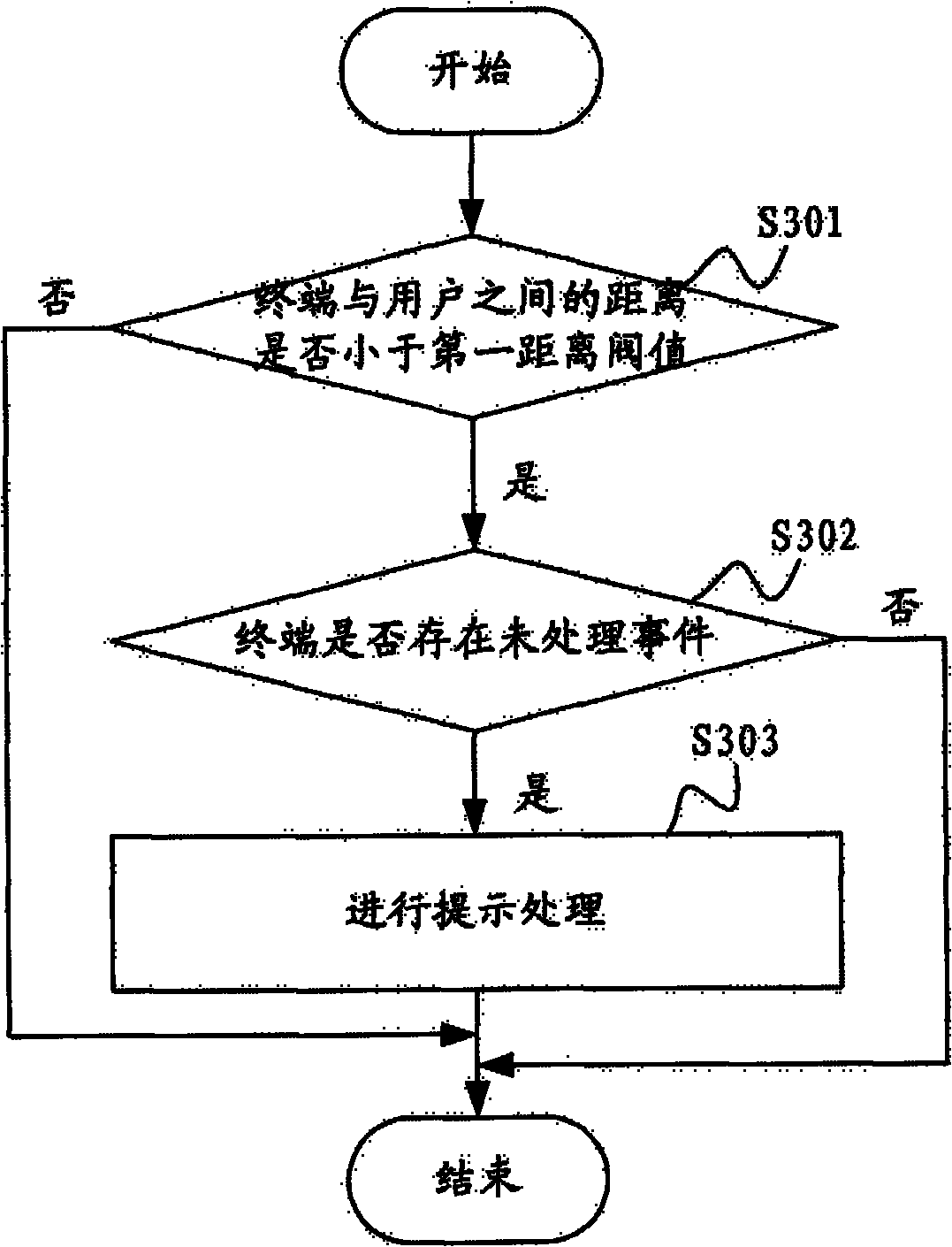

Unprocessed event indicating method, system and terminal

The invention is applied in the technical field of communication, and provides an unprocessed event indicating method, an unprocessed event indicating system and a terminal. The method comprises the following steps of: judging whether a distance between the terminal and a user is less than a first preset distance threshold value or not; if the distance is less than the first distance threshold value, judging whether the terminal has an unprocessed event or not; and if the terminal has the unprocessed event, performing indication processing. Preferably, in the indication processing, the terminal produces prompt tones / vibration, also can actively perform screen unlocking, and displays an interface corresponding to the unprocessed event. Therefore, by the method, the system and the terminal,the unprocessed event can be indicated at a proper time, so that the user can timely and conveniently view the unprocessed event.

Owner:YULONG COMPUTER TELECOMM SCI (SHENZHEN) CO LTD

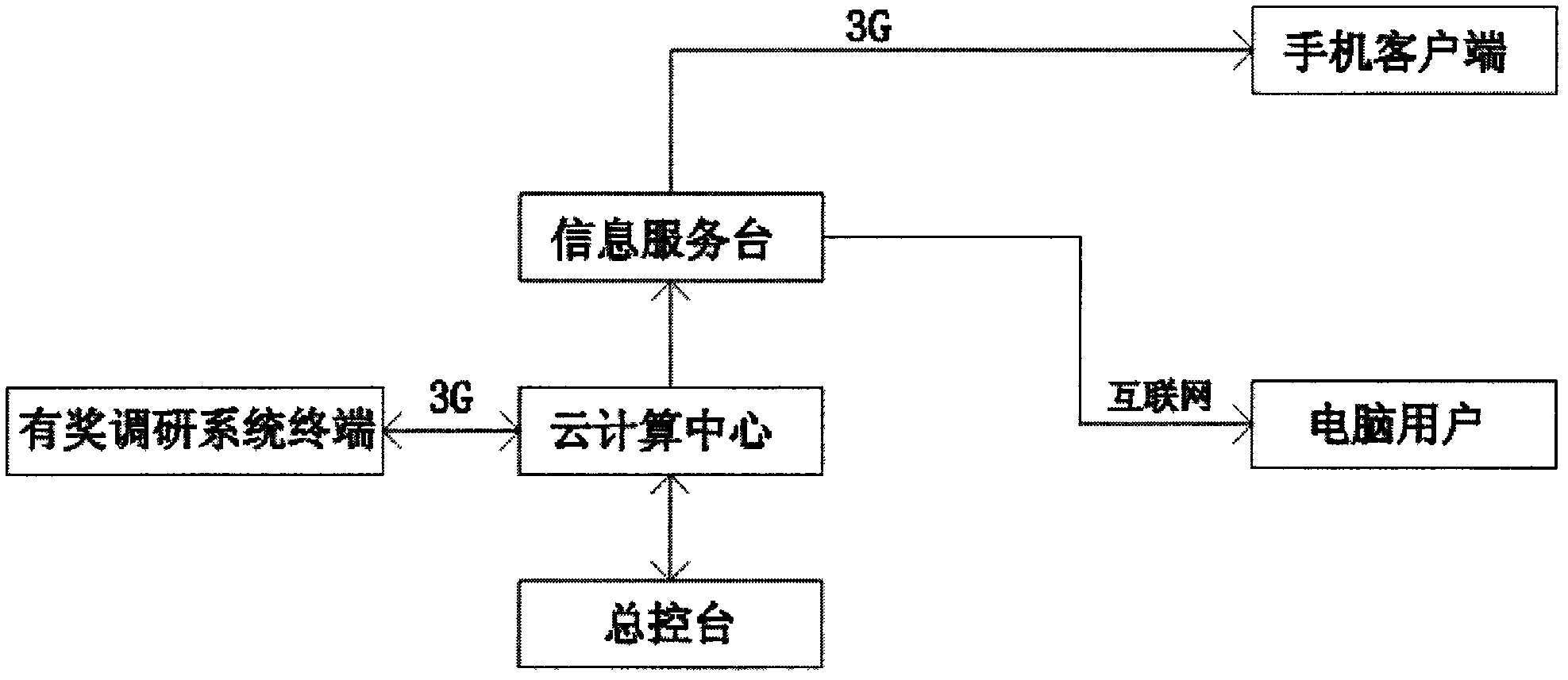

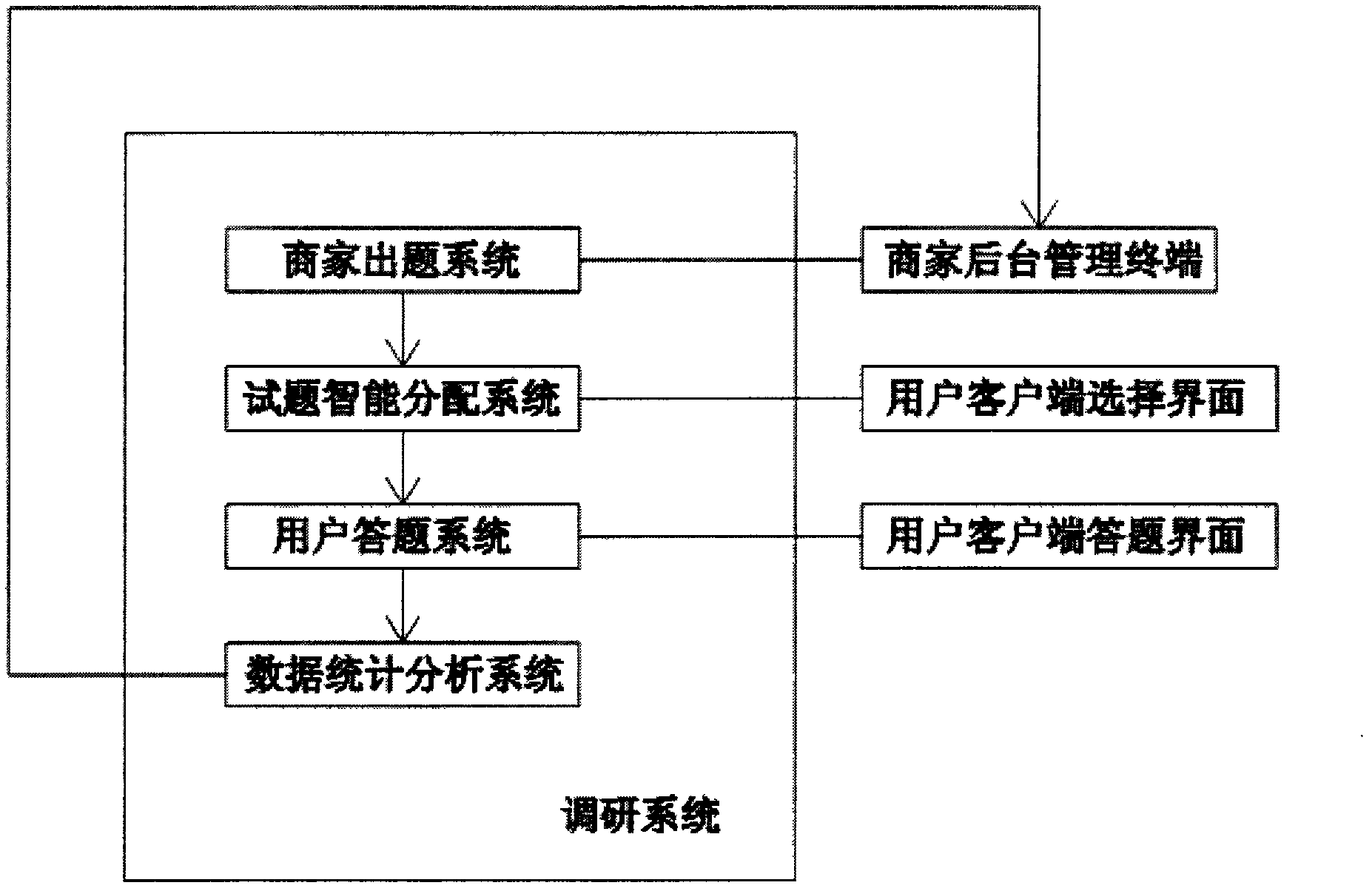

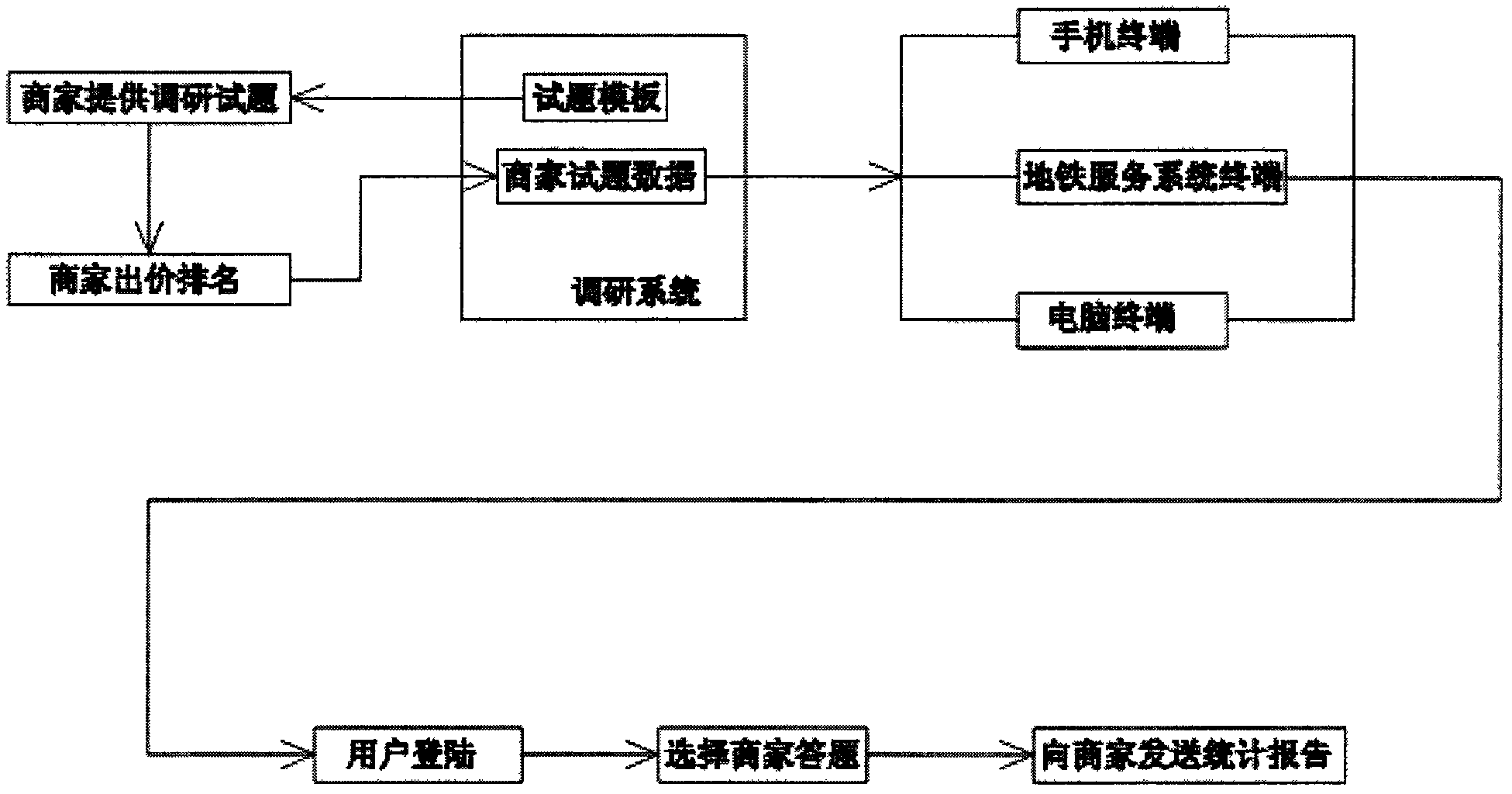

Premium investigation system with accurate advertisement dissemination effect

The invention discloses a premium investigation system with an accurate advertisement dissemination effect, which is based on a premium investigation system terminal and an information service model of a website. The investigation system comprises a businessman question make-out system, a user answering system, an intelligent question allocation system and a data statistics analysis system. The investigation system provided by the invention can be landed with the aid of special ID information through Internet, the businessman can make out questions according to a question template; users can answer the questionnaire, obtain compensation, and participate in a campaign of drawing a lottery; and a statistics report can be sent to the businessman through the system. Through the system provided by the invention, a traditional model that the advertising information is passively received by audiences is changed, and the billing is performed according to the watching and right comprehension of audiences, so the historic breakthrough from the price to the value of the advertisement is realized, the real-time dynamic monitoring is achieved, the accurate advertisement effect can be measured, and the audiences can gain the advertising information and a certain remuneration during entertainment, and accordingly, the user experience value is promoted, and the interactive watching becomes the mainstream and trend.

Owner:深圳市英尔科技有限公司

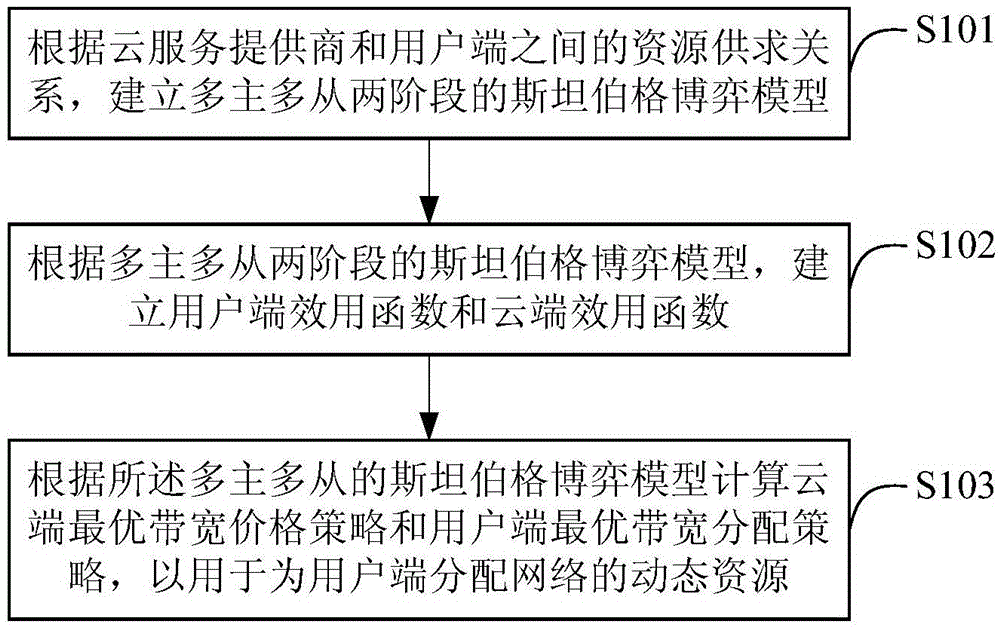

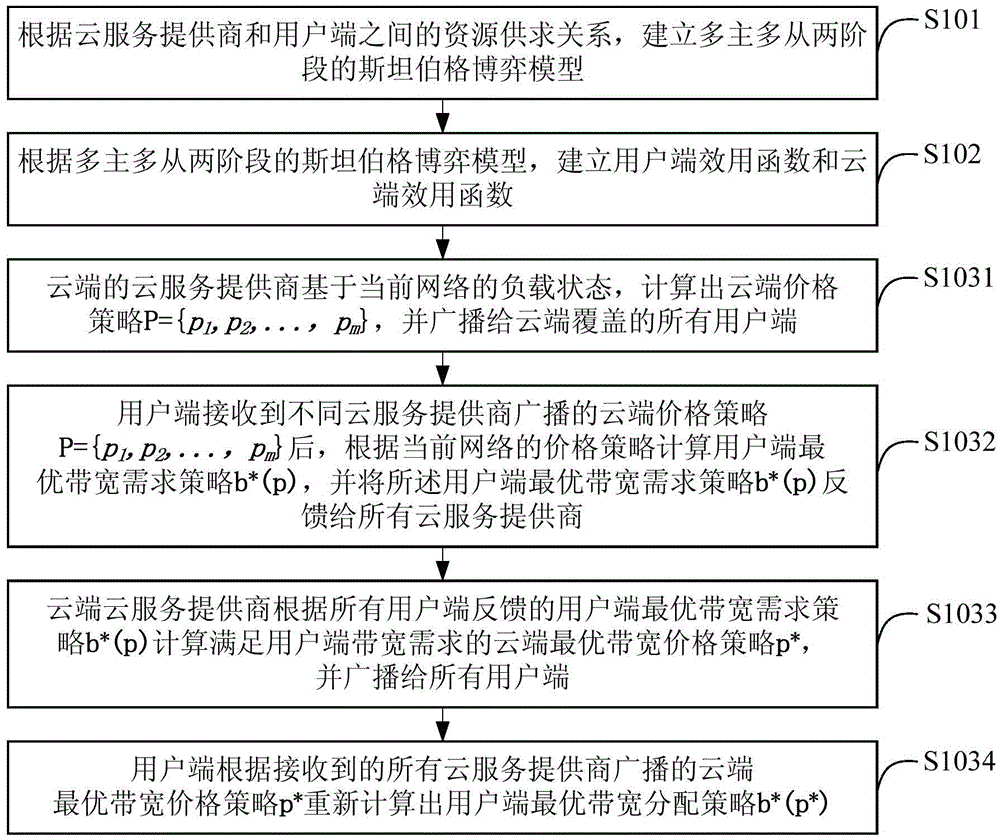

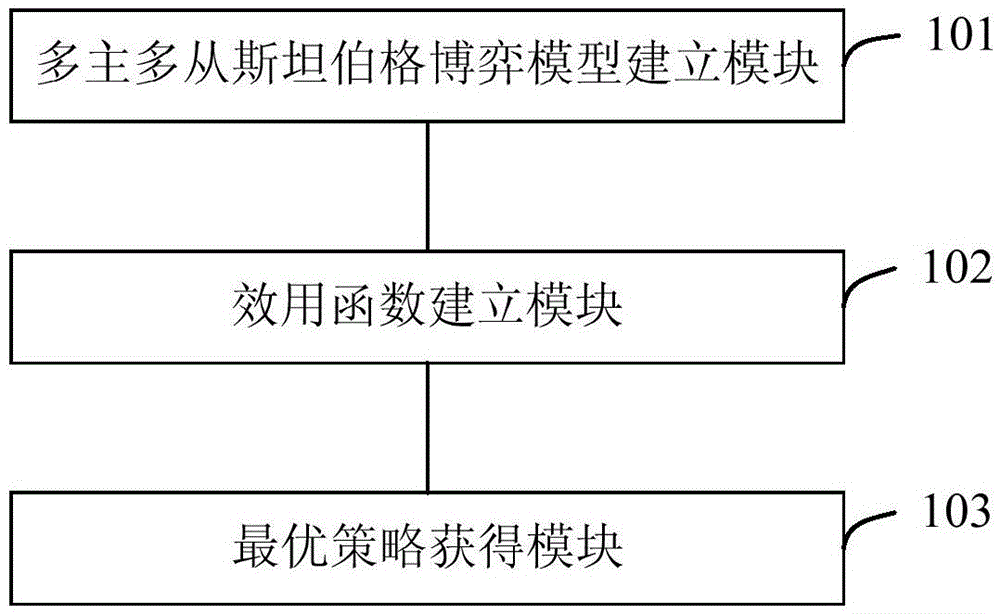

Network dynamic resource calculating method and device

ActiveCN105657750AImprove experience valuePerformance maximizationNetwork traffic/resource managementDynamic resourceCloud service provider

The embodiment of the invention discloses a network dynamic resource calculating method and device. According to the scheme provided by the embodiment of the invention, firstly, a cloud service provider and a client with a resource supply and demand relationship are converted into a multi-master multi-slave two-stage Stackelberg game model; according to the multi-master multi-slave two-stage Stackelberg game model, a cloud utility function and a client utility function are built; according to the multi-master multi-slave two-stage Stackelberg game model, an optimum cloud bandwidth price strategy and an optimum client bandwidth allocation strategy are computed for allocating dynamic resources of a network to the client. In application of the method provided by the embodiment of the invention, the dynamic network resource demands of the client are computed; the network performance is maximized; the dynamic network resource demands of the client are satisfied; and the user experience rank is promoted.

Owner:BEIJING UNIV OF POSTS & TELECOMM

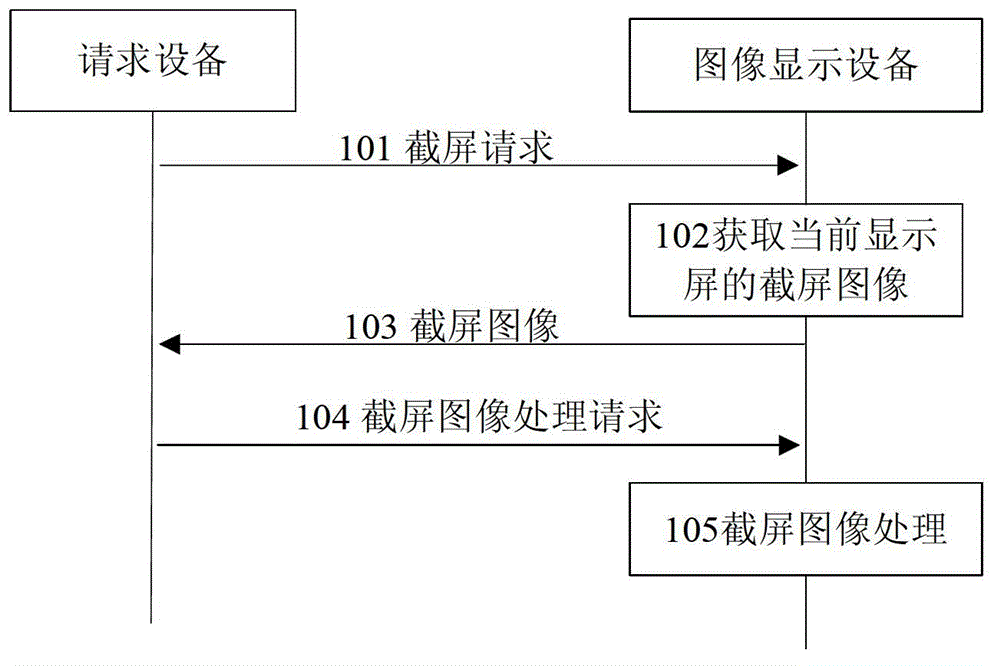

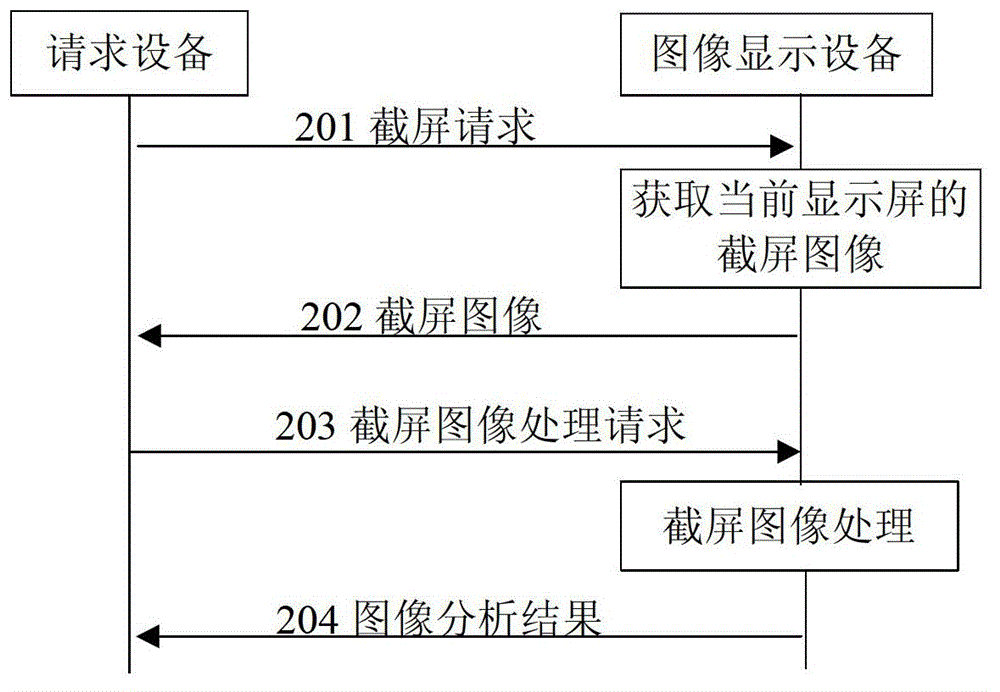

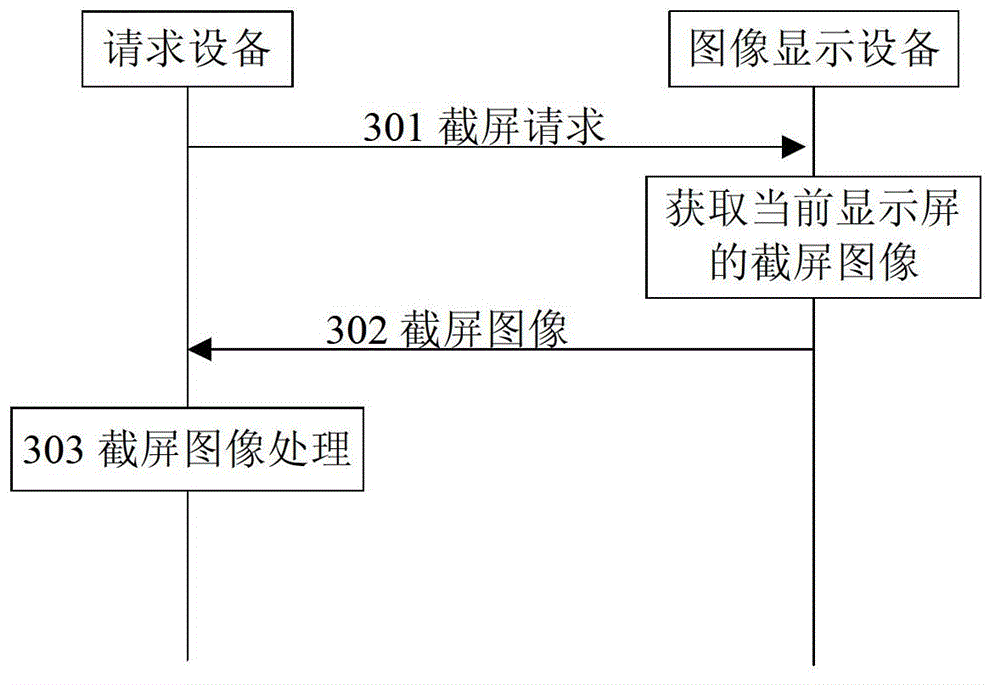

Screen capture application method, equipment and system

InactiveCN103338405AImprove user experience valueImprove experience valueSelective content distributionImage analysisScreen capture

The invention relates to a screen capture application method. The method comprises steps that: a screen capture request sent by request equipment is received: a screen capture image of a present display screen is acquired; the screen capture image is sent to the request equipment; a screen capture image processing request sent by the request equipment is received, the screen capture image processing request comprises a screen capture image or an area screen capture image; image analysis on the screen capture image or the area screen capture image is carried out, an image analysis result is displayed on the display screen or is sent to the request equipment, or image sharing of the screen capture image or the area screen capture image is carried out. The screen capture application method supports a user to carry out selective screen capture sharing or information searching of display frames of image display equipment such as a television set through the request equipment such as an intelligent terminal and improves user experience values.

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

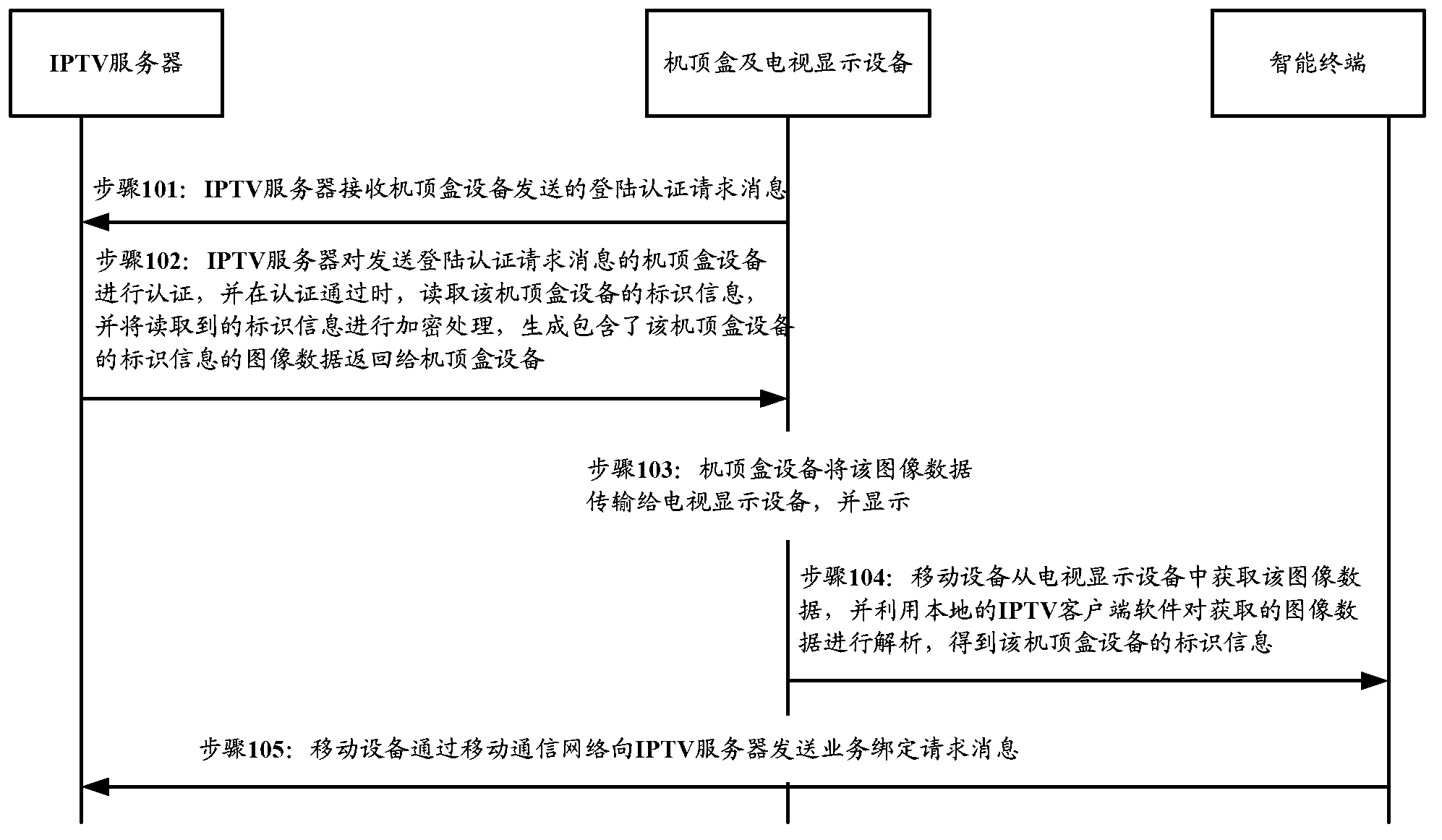

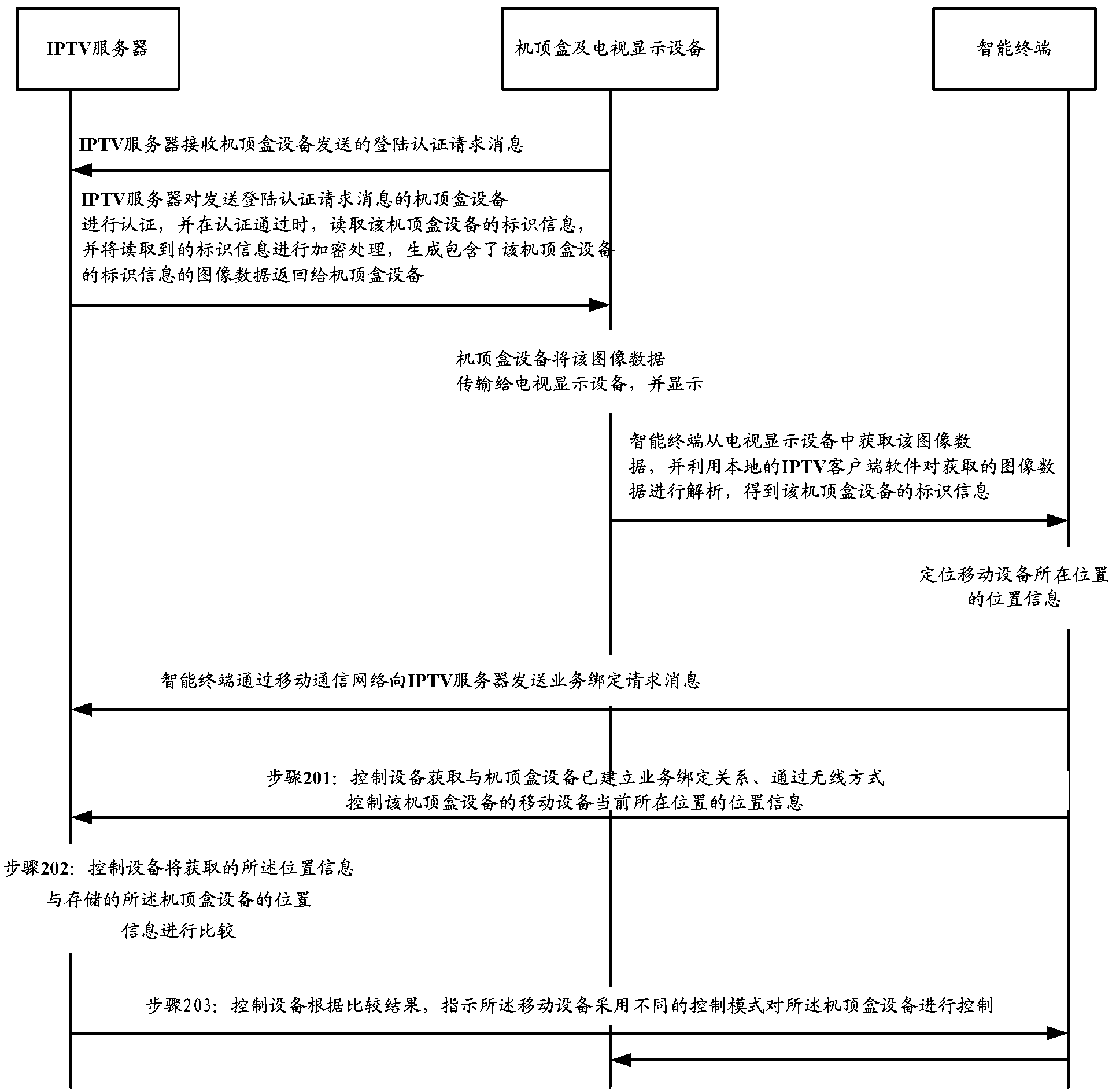

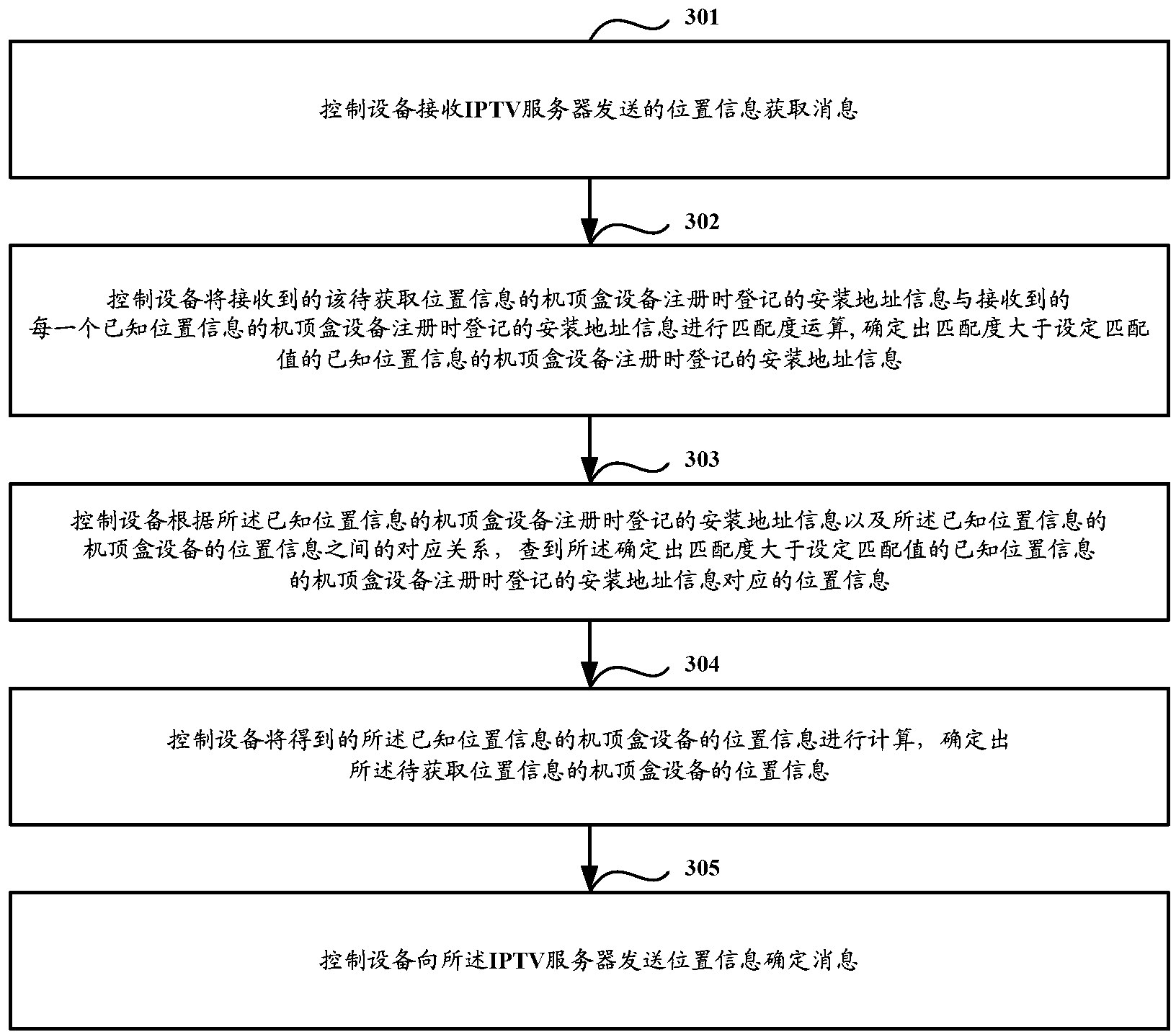

Equipment controlling set top box, method of confirming position information and issuing information and equipment

ActiveCN103260059AEasy to controlFlexible controlSelective content distributionControl setControl manner

The invention discloses equipment controlling set top box, a method of confirming position information and issuing information and equipment. The equipment controlling set top box, the method of confirming the position information and issuing the information and the equipment mainly includes the following steps. After a set-up service binding relation with set top box equipment and information on a current position of moving equipment which controls the set top box equipment in a wireless mode are obtained, the information on the current position of the moving equipment is compared with stored information on a position of the set top box equipment. According to a comparison result, the moving equipment is instructed to control the set top box equipment in different control modes. Thus, by accurately obtaining the set-up service binding relation with the set top box equipment and a relative position relation between the moving equipment which controls the set top box equipment in a wireless mode and the set top box equipment, the moving equipment can select a proper control mode to control the set top box equipment during movement. A control mode of the moving equipment on the set top box equipment is flexible, control precision of the moving equipment on the set top box equipment is improved and experience values of users are improved.

Owner:HUAWEI TECH CO LTD

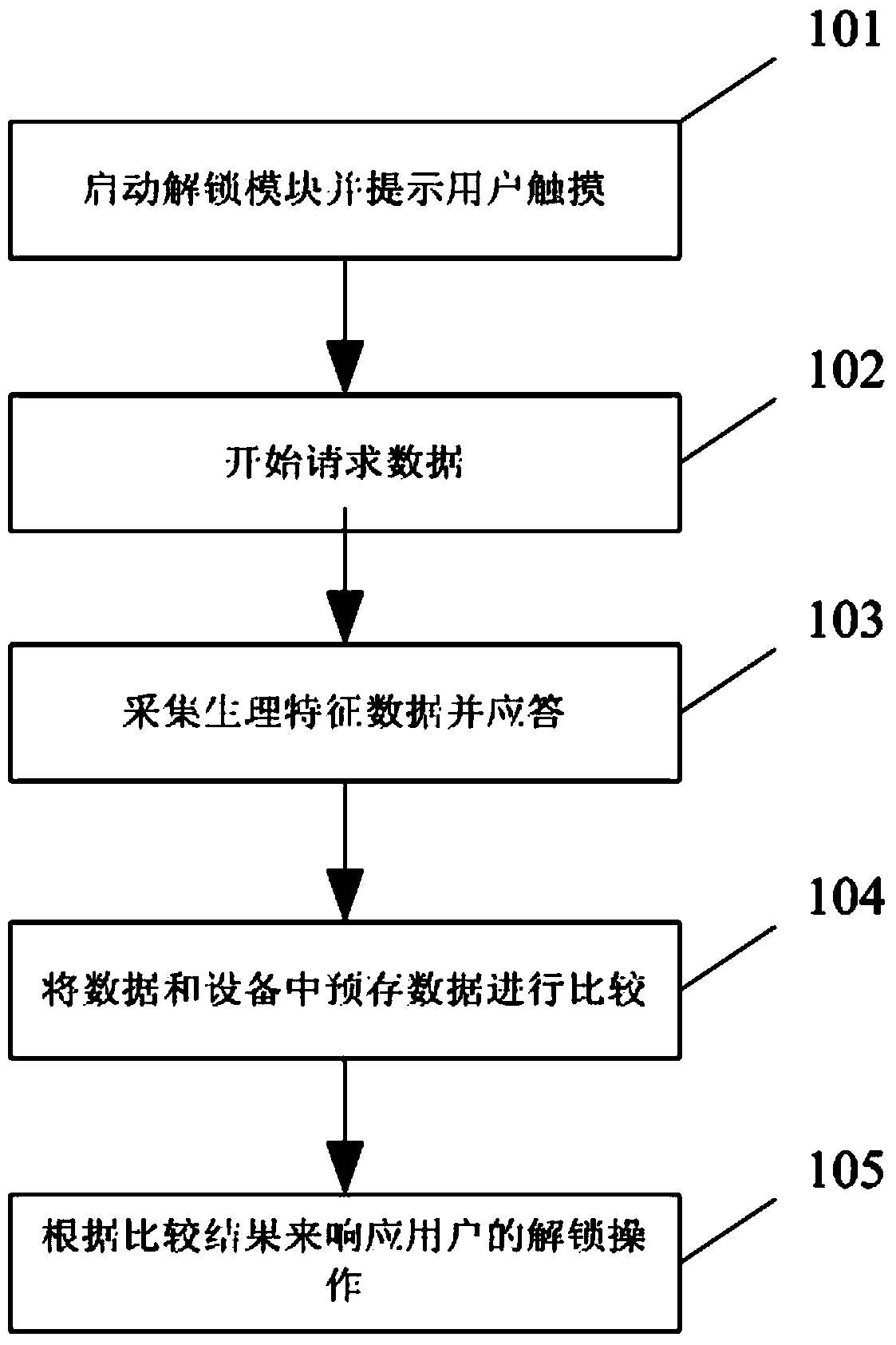

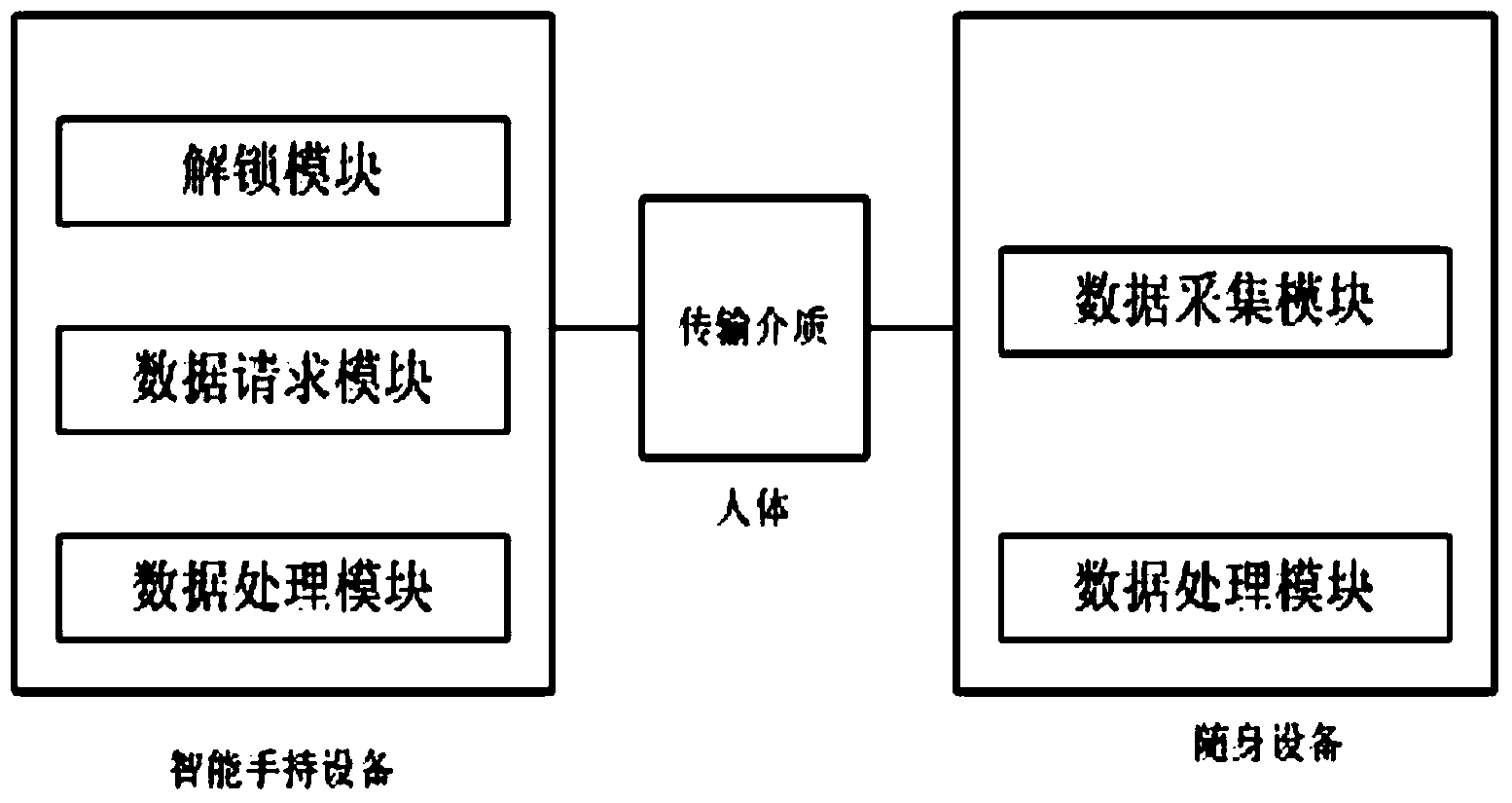

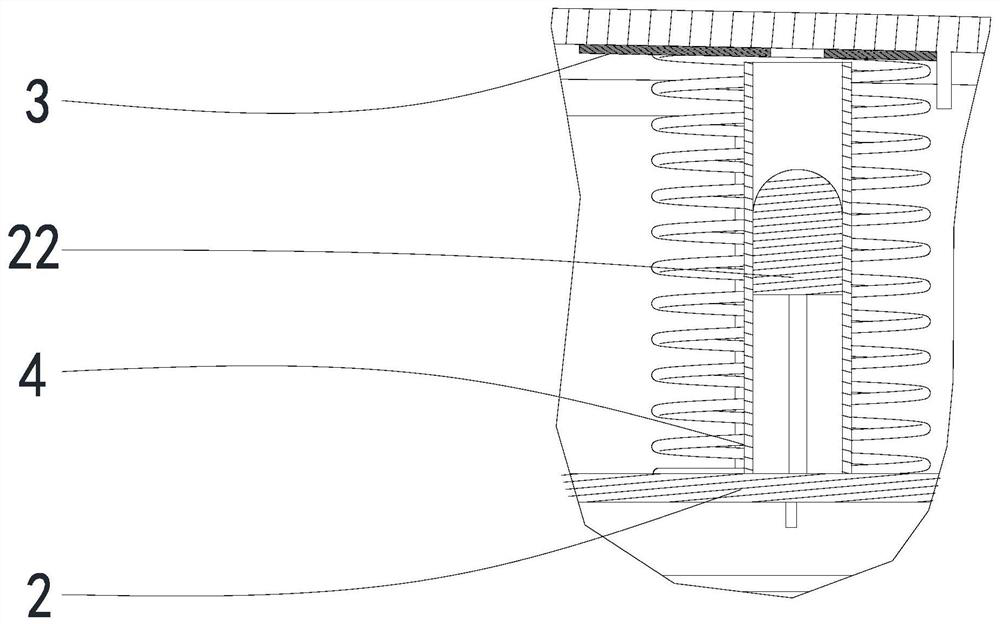

Unlocking system and method for intelligent handheld equipment

InactiveCN104360731AImprove experience valuePerfect intelligenceInput/output for user-computer interactionGraph readingData transmissionHandheld equipment

The invention relates to the unlocking technology of an intelligent terminal, discloses an unlocking system and method for intelligent handheld equipment and solves the problems of low security and complicated operation of the intelligent handheld equipment unlocking scheme in the traditional technology. When a user starts up an unlocking module and touches corresponding hardware parts of the intelligent handheld equipment, the body of the user serves as a data transmission medium to broadcast an unlocking request to the user, portable equipment on the body of the user acquires corresponding information in the request to serve as response information after receiving the unlocking request and transmits the response information to the intelligent handheld equipment, and the intelligent handheld equipment compares the response information with pre-stored feature information to determine whether to unlock or not. The unlocking system and method are suitable for quickly unlocking various intelligent handheld equipment.

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

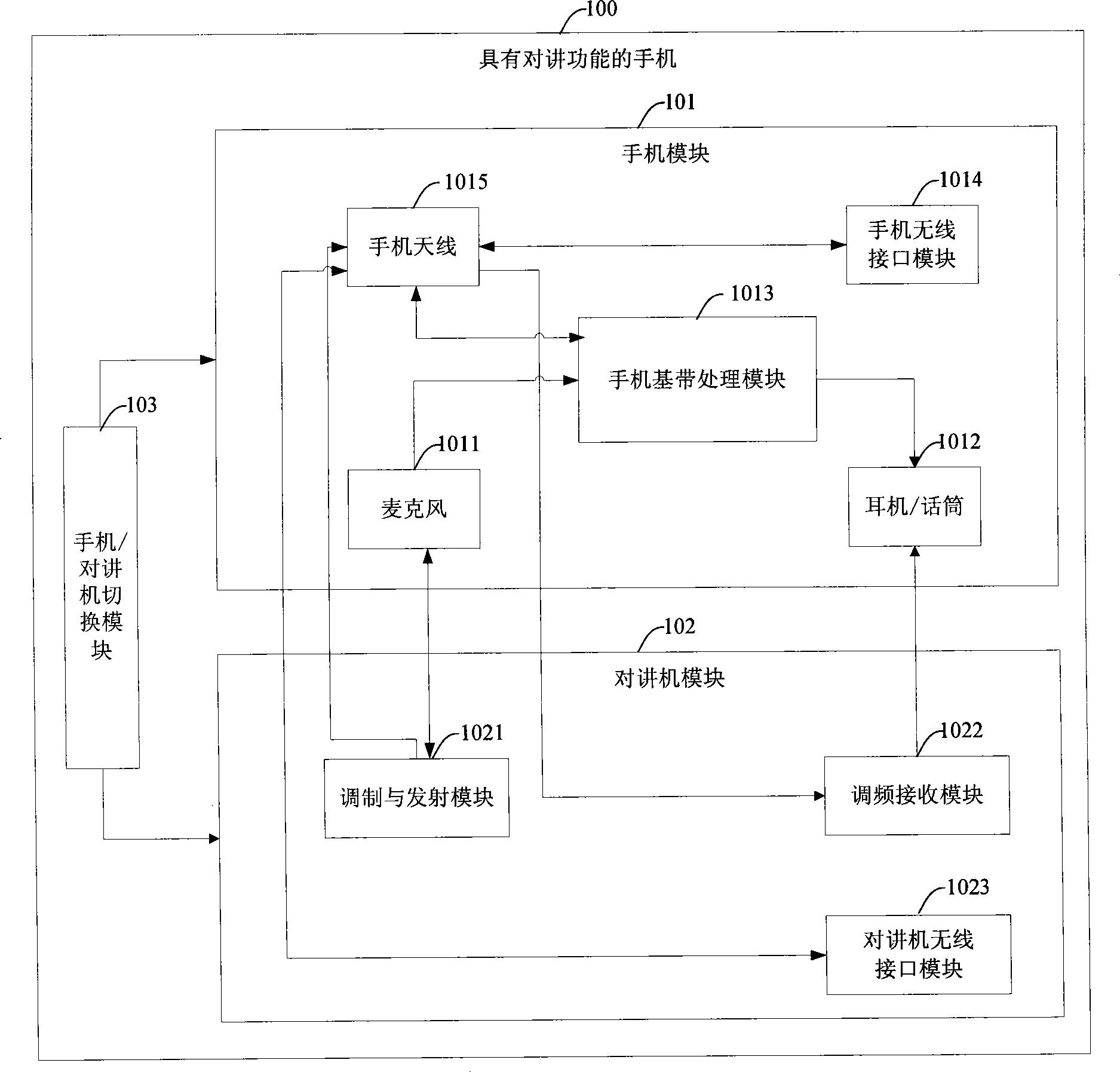

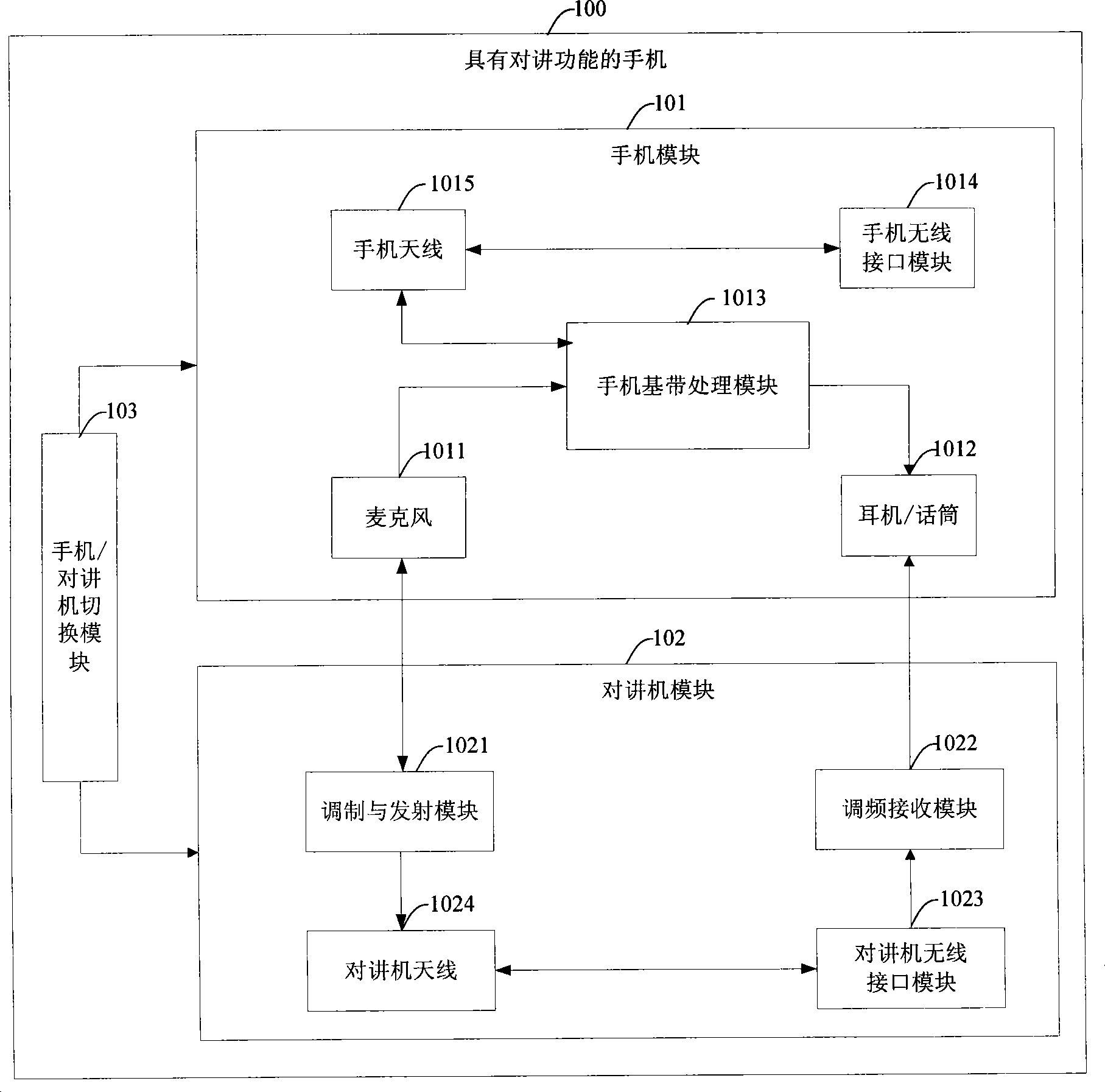

Mobile phone having intercom function

InactiveCN101459720AReal-time interactiveImprove user experience valueSubstation equipmentTransmissionHandsetShort range wireless

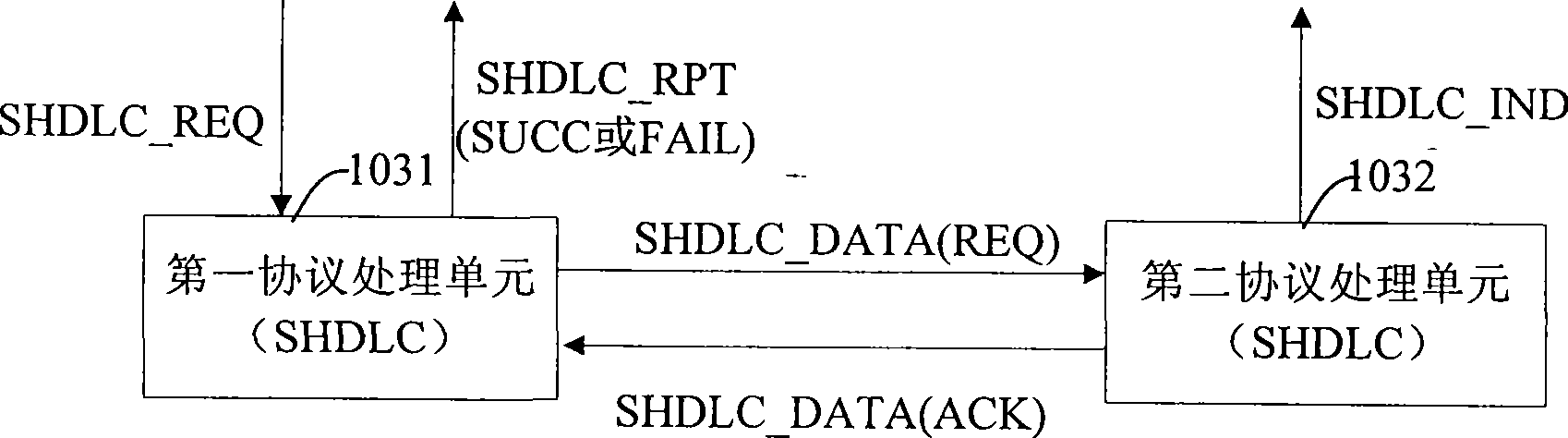

The invention discloses a handset with intercommunication functions, which is used to carry out far and near distance communication through different modes, wherein the handset comprises a handset module and an interphone module, wherein the interphone module is a wireless duplex interphone module. The interphone module also can comprise a modulation and emission module which is connected with the handset module and is used to receive voice signals of users and to modulate and emit the voice signals of the users, and an FM receiving module which is connected with the handset module and is used to receive the signals sent by the modulation and emission module of the corresponding end to demodulate and play. Thereby, the handset realizes wireless dialog with low cost and short distance and even free short distance wireless dialog, the wireless dialog has real time interaction, and the user experience is improved.

Owner:KONKA GROUP

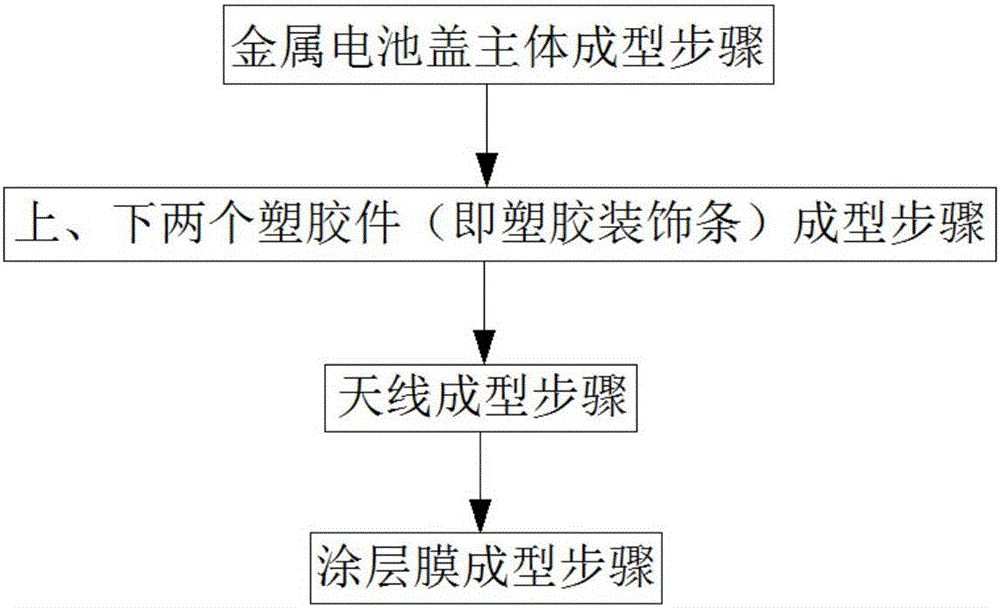

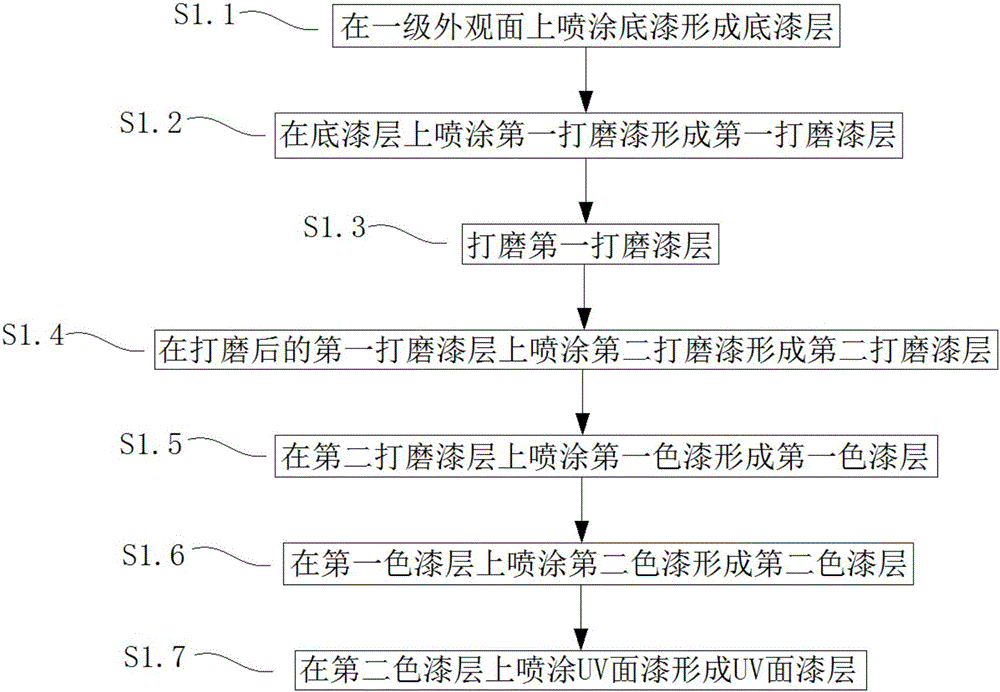

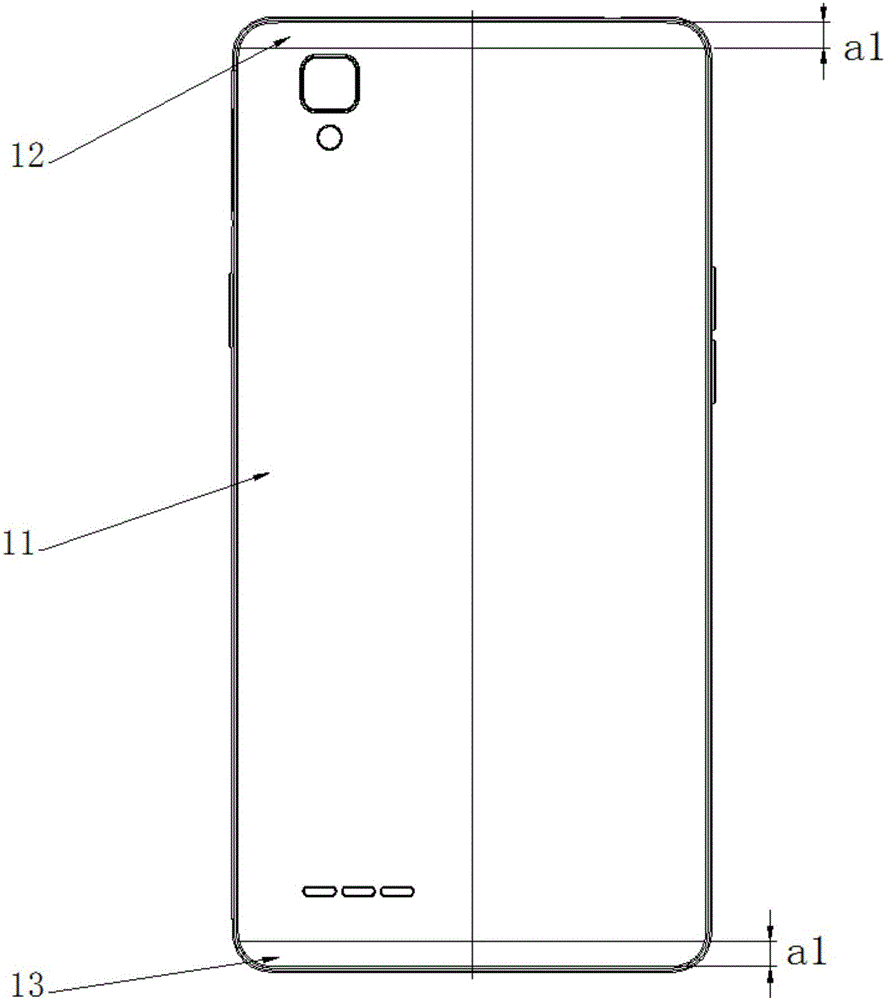

Mobile telephone shell processing technology, mobile telephone shell and mobile telephone

ActiveCN106210201AImprove the sense of hardwareEnhance the sense of hardwareAntenna supports/mountingsPretreated surfacesLaser etchingEngineering

The invention relates to a mobile telephone shell processing technology, a mobile telephone shell and a mobile telephone. According to the mobile telephone shell processing technology, coating film is formed on first-level appearance surfaces through spraying and polishing technologies or through spraying, polishing, vacuum plating and laser etching technologies; the coating film covers antennas and the areas in the first-level appearance surfaces except the antennas; and the thickness of the coating film is less than or equal to 65 mum. The mobile phone shell comprises plastic elements. The antennas and the coating film are arranged on the first-level appearance surfaces of the plastic elements. The coating film covers the antennas and the areas in the first-level appearance surfaces except the antennas; and the thickness of the coating film is less than or equal to 65 mum. The mobile phone provided by the invention comprises the mobile phone shell. According to the mobile telephone shell processing technology, the mobile phone shell integrally is equipped with good hardware feeling, and the cost is relatively low. The mobile phone shell and the mobile phone have good hardware feeling, and the cost is relatively low.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

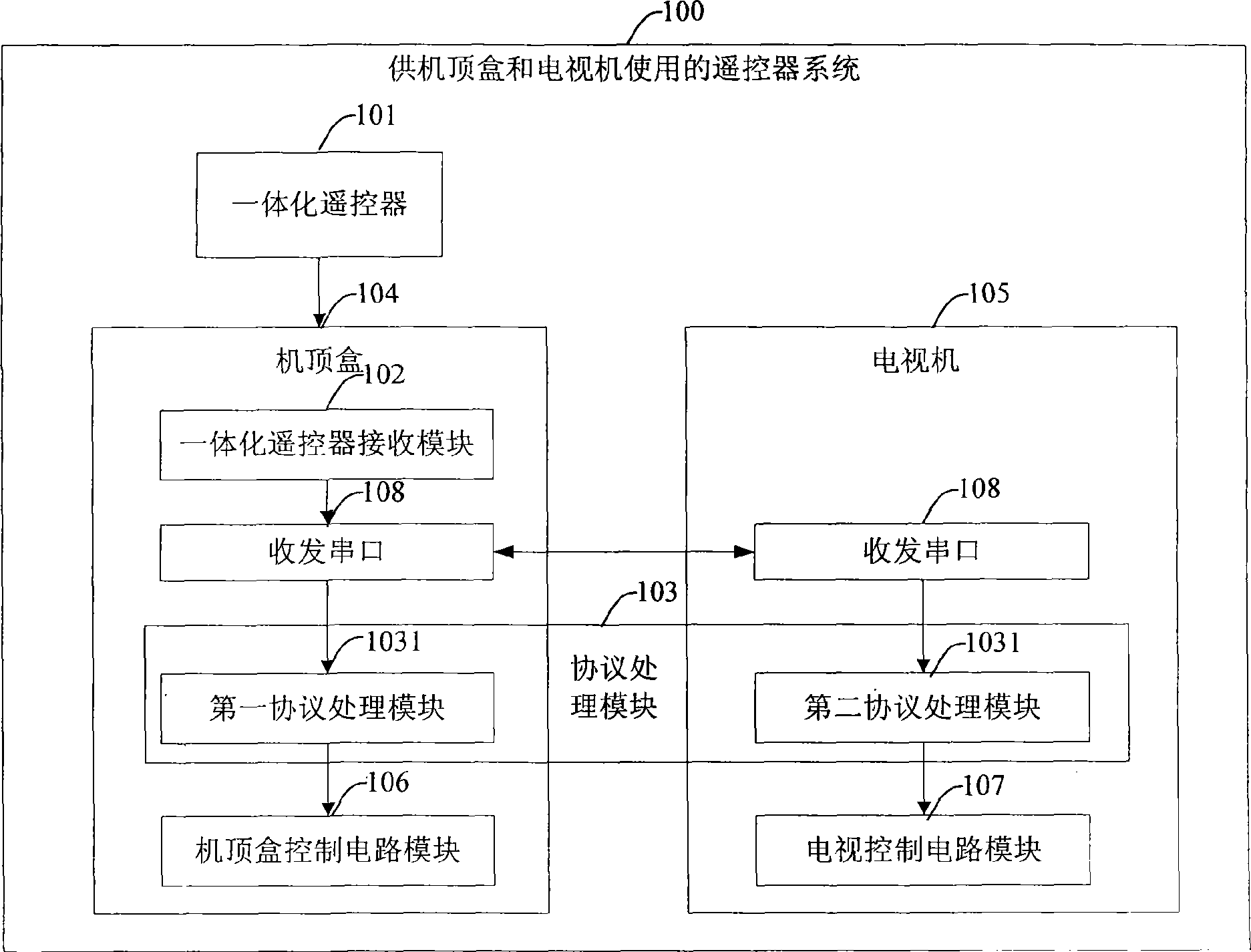

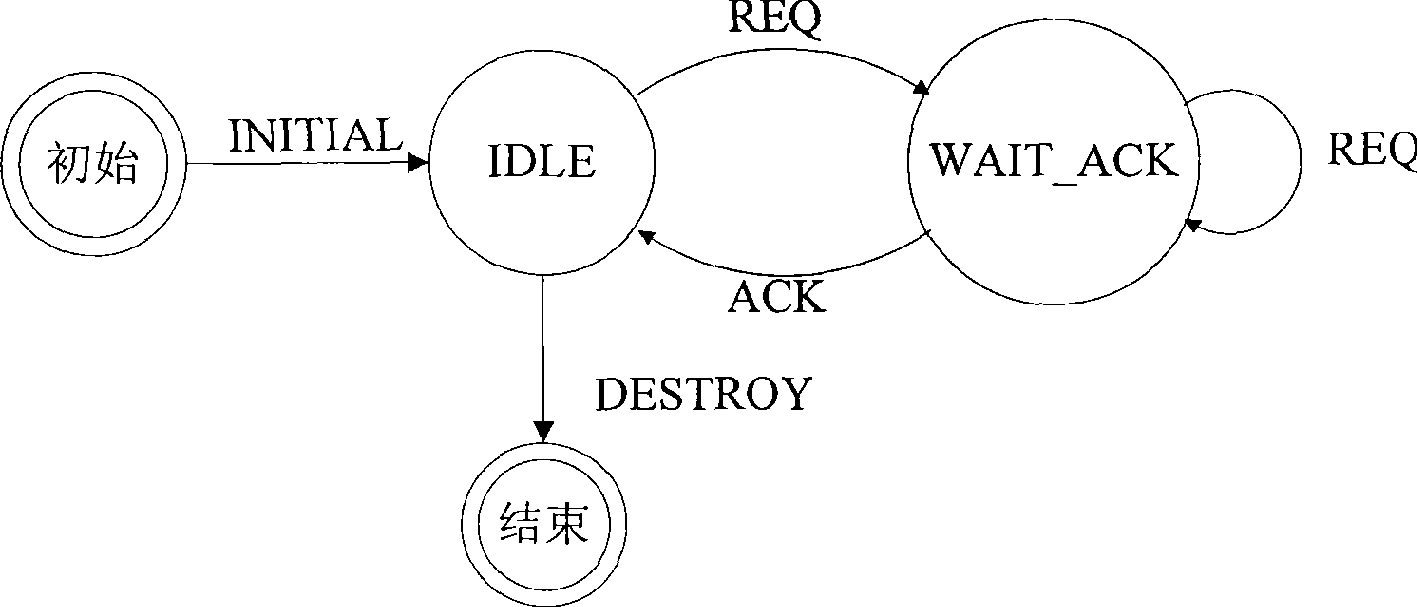

Remote controller system for set-top box and television set as well as implementing method thereof

InactiveCN101465950AImprove experience valueTelevision system detailsColor television detailsMultiplexingControl signal

The invention discloses a remote controller system for a set-top box and a television set. The remote controller system comprises an integrative remote controller, an integrative remote controller receiving module, a set-top box control circuit module and a television set control circuit module; the integrative remote controller is used for sending function control signals which comprise a multiplexing function control signal, a set-top box function control signal and a television set function control signal; the integrative remote controller receiving module is used for receiving and transmitting the function control signals to the set-top box control circuit module and / or the television set control circuit module; the set-top box control circuit module is used for controlling the set-top box according to the received function control signals; the television control circuit module is used for controlling the television set according to the received function control signals. The remote controller system provides a method of realizing the remote controller system for the set-top box and the television set. Therefore, the user experience value is improved.

Owner:KONKA GROUP

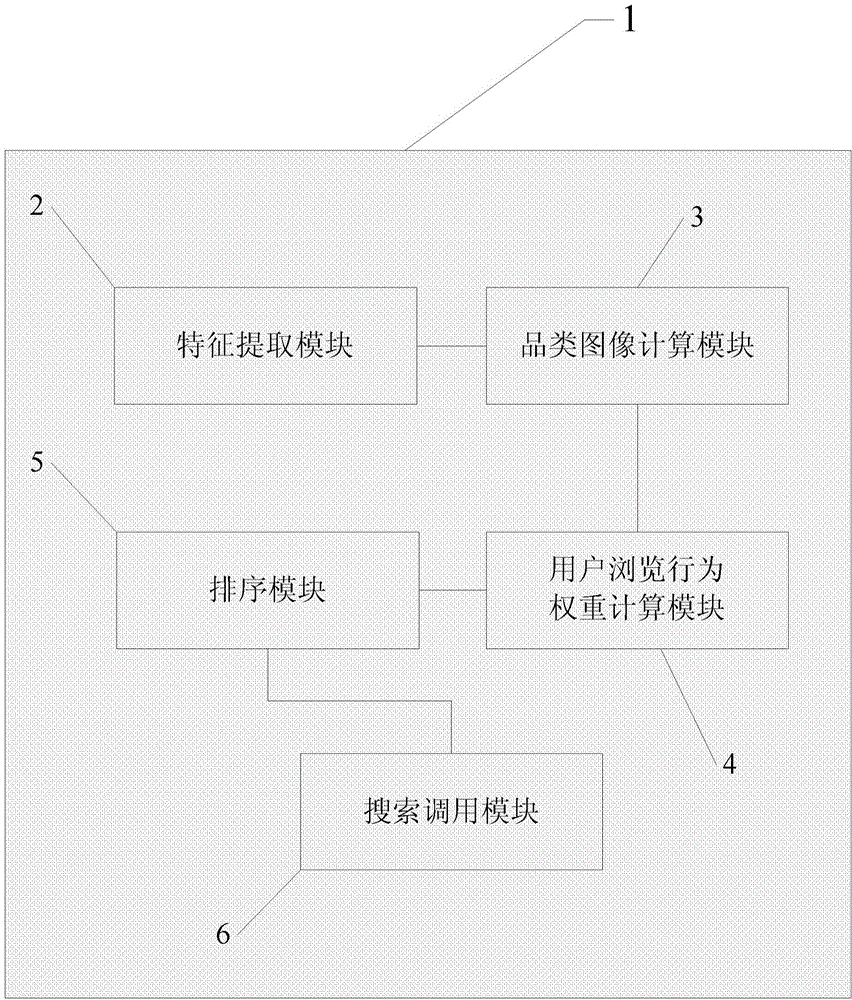

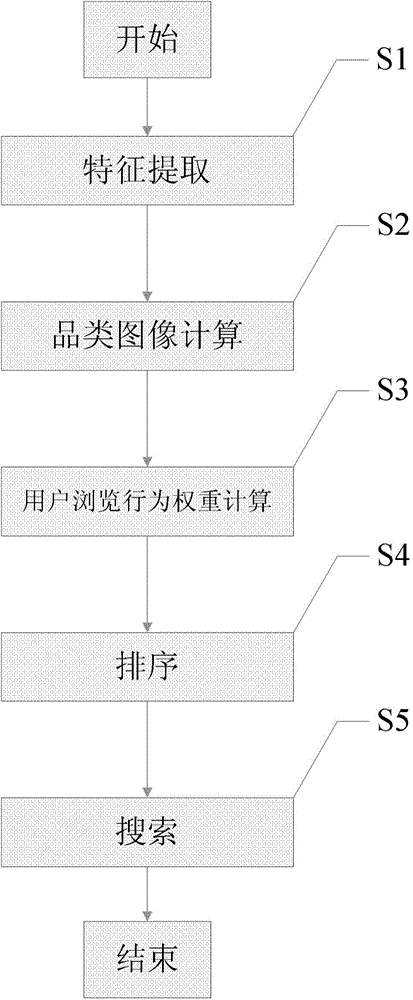

Device and method for personalized search based on commodity image features

InactiveCN104881798AImprove experience valueCharacter and pattern recognitionNeural architecturesFeature vectorPersonalized search

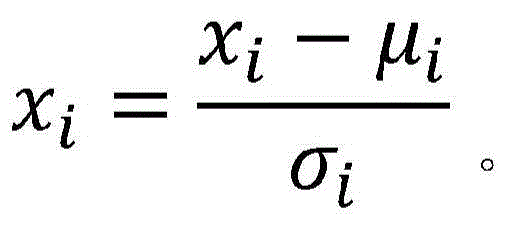

The invention discloses a device and a method for personalized search based on commodity image features. The device comprises a feature extraction module, a category image calculation module, a user browsing behavior weight calculation module, a ranking module and a search calling module, wherein the feature extraction module extracts abstract semantic feature vectors of images by using a neural network model; as for the abstract semantic feature vectors of each dimension, the category image calculation module calculates the mean and the variance at the dimension and carries out normalization processing according to each dimension; the user browsing behavior weight calculation module extracts the corresponding normalized abstract semantic feature vectors of images browsed by a user according to categories and carries out summation, thereby acquiring an interest weight vector of the user at each category; the ranking module carries out inner product on corresponding feature vectors of images which are not viewed by the user at a certain category according to the interest weight vector of the user at the category, acquires a score value corresponding to each image, ranks according to the score values, selects a specified number of images whose score values are high and puts the images into storage; and the search calling module carries out personalized search according to a ranking value result.

Owner:BEIJING JINGDONG SHANGKE INFORMATION TECH CO LTD +1

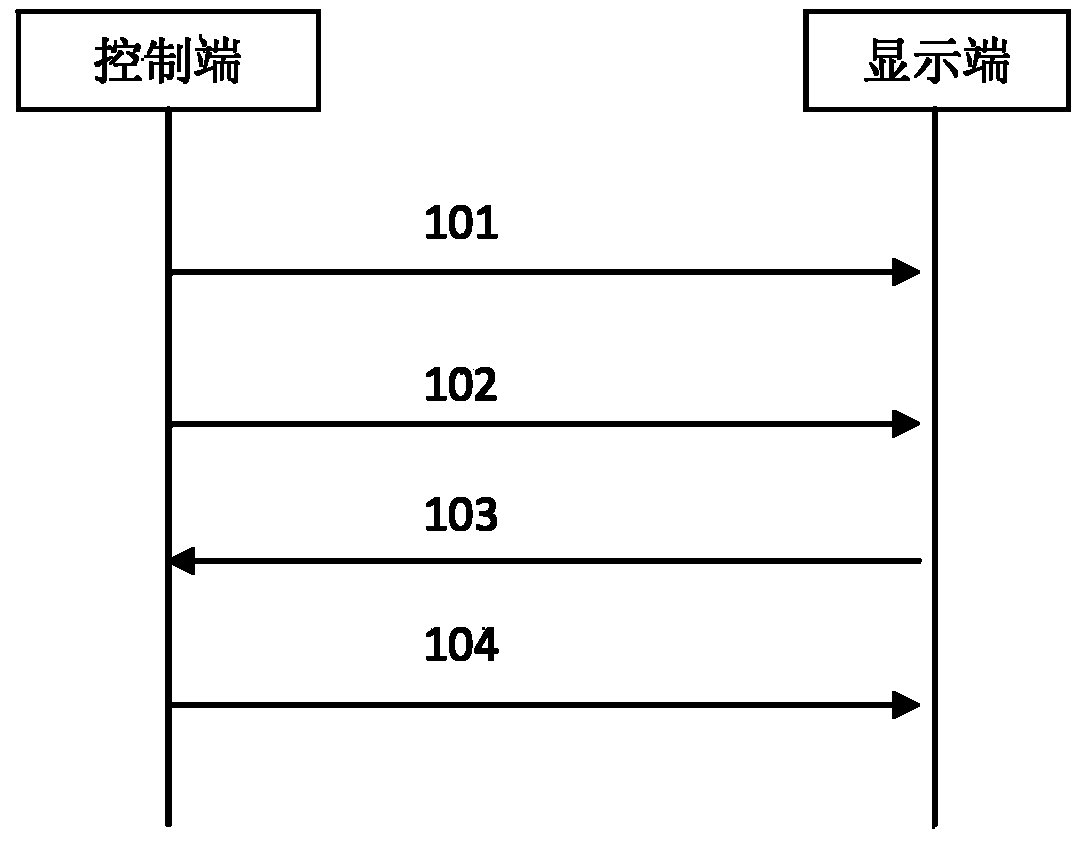

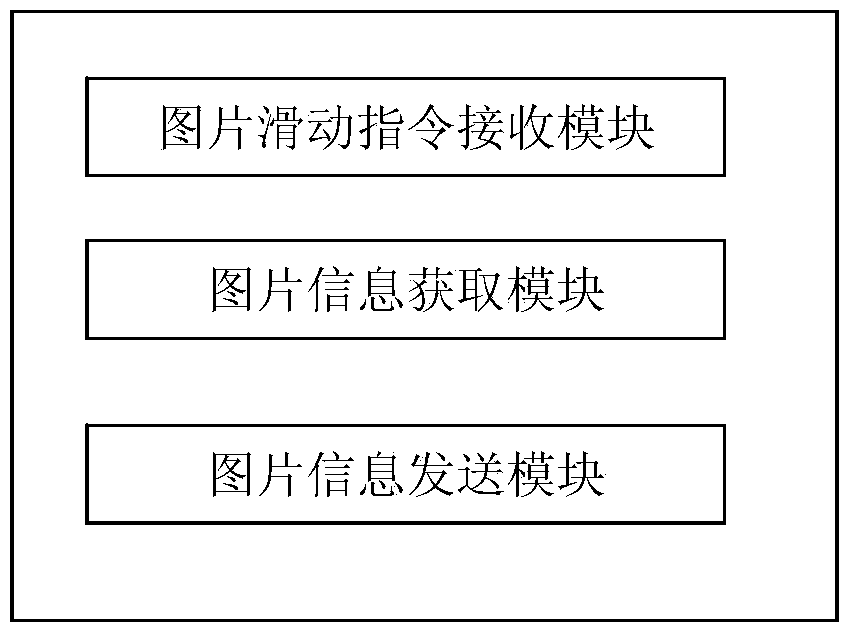

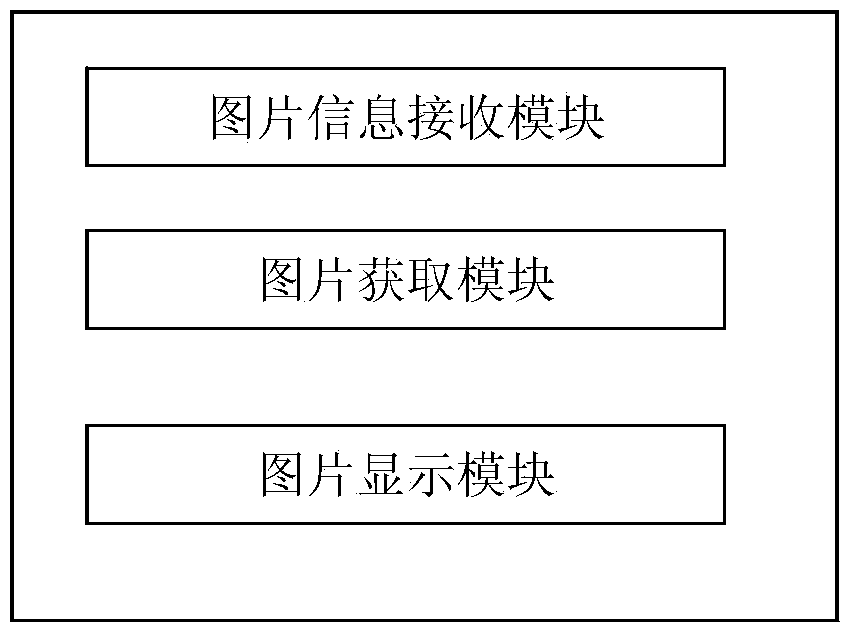

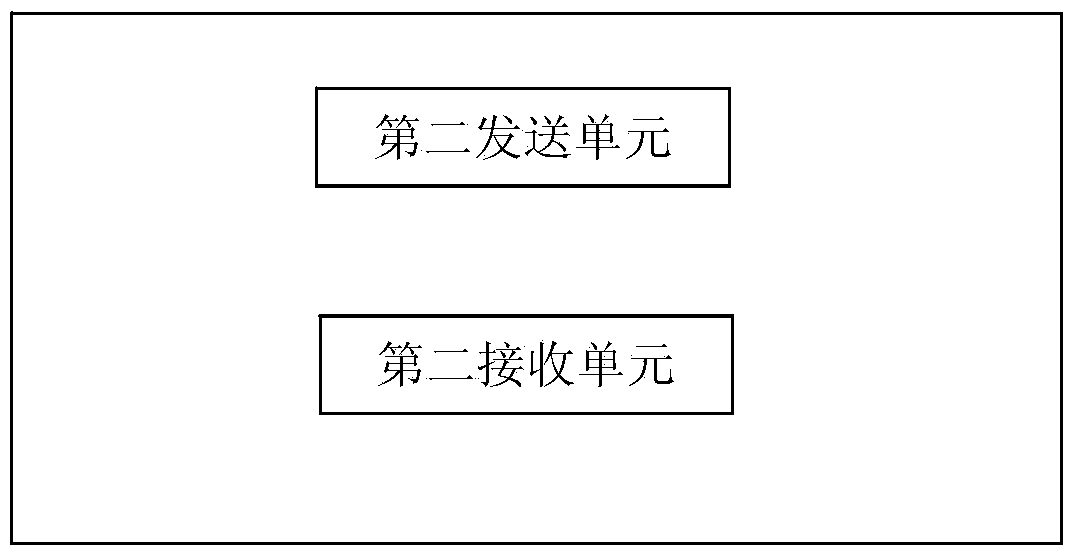

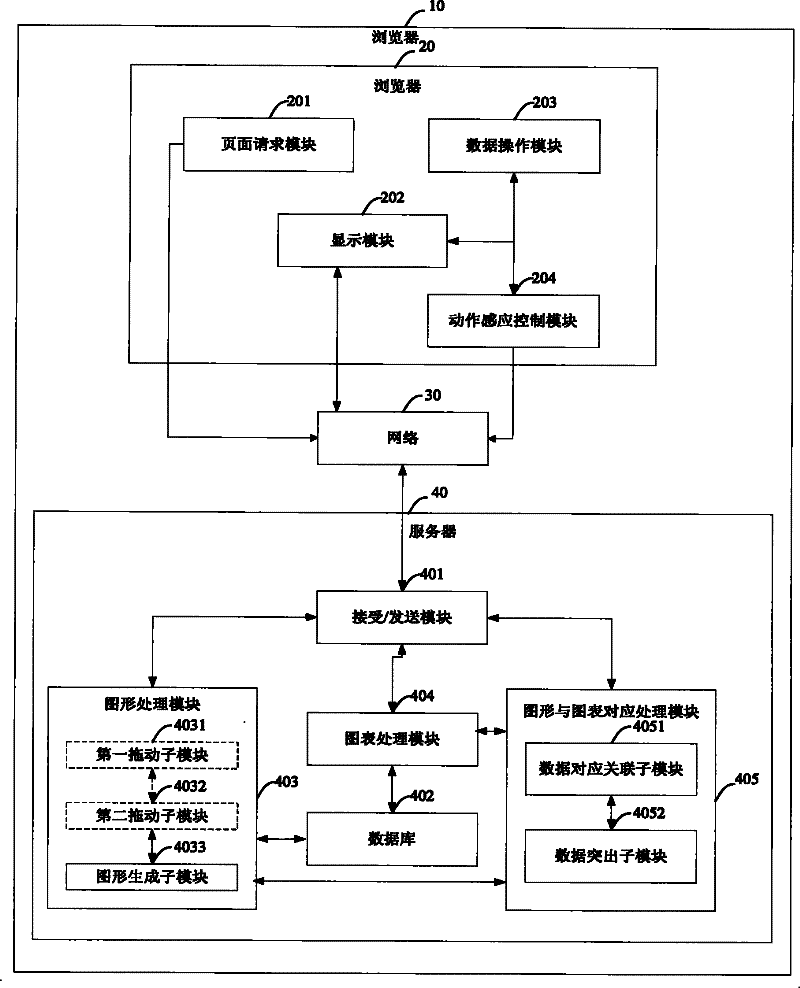

Method, control terminal, display terminal and system for image browsing

InactiveCN103796073AGood real-time performanceImprove user experience valueSelective content distributionComputer hardwareImage acquisition

The invention relates to the field of intelligent terminals, in particular to a method, device and system for image browsing, and aims to meet the requirement of a user for sharing images by displaying the images on a smart television and other large screen devices through intelligent terminals. The system for image browsing comprises a control terminal and a display terminal, wherein the control terminal and the display terminal are connected through a communication network. The control terminal comprises an image sliding instruction receiver module, an image information acquisition module and an image information transmitter module. The display terminal comprises an image information receiver module, an image acquisition module and an image display module. The invention further provides the method for image browsing. The method, device and system are applicable to image browsing.

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

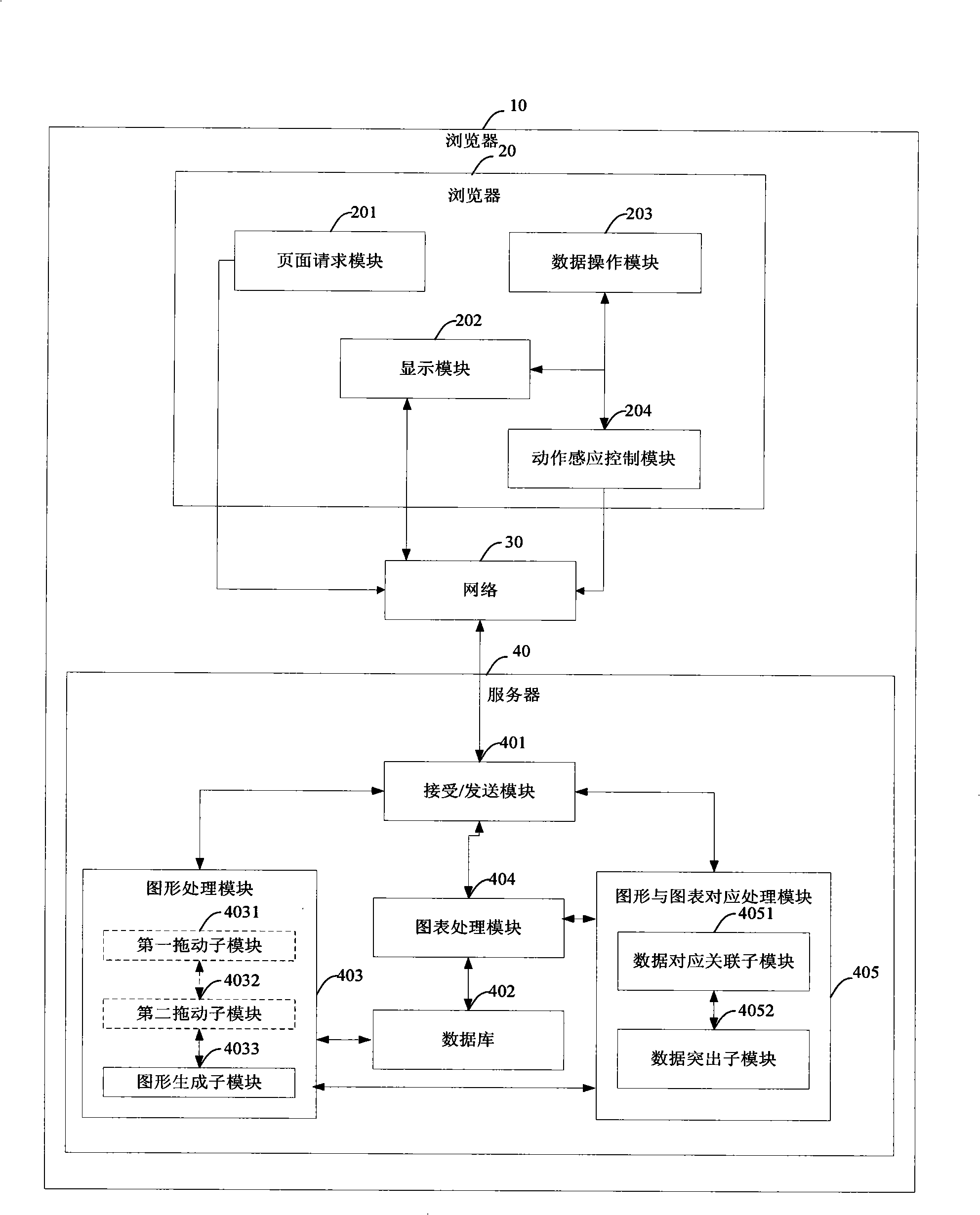

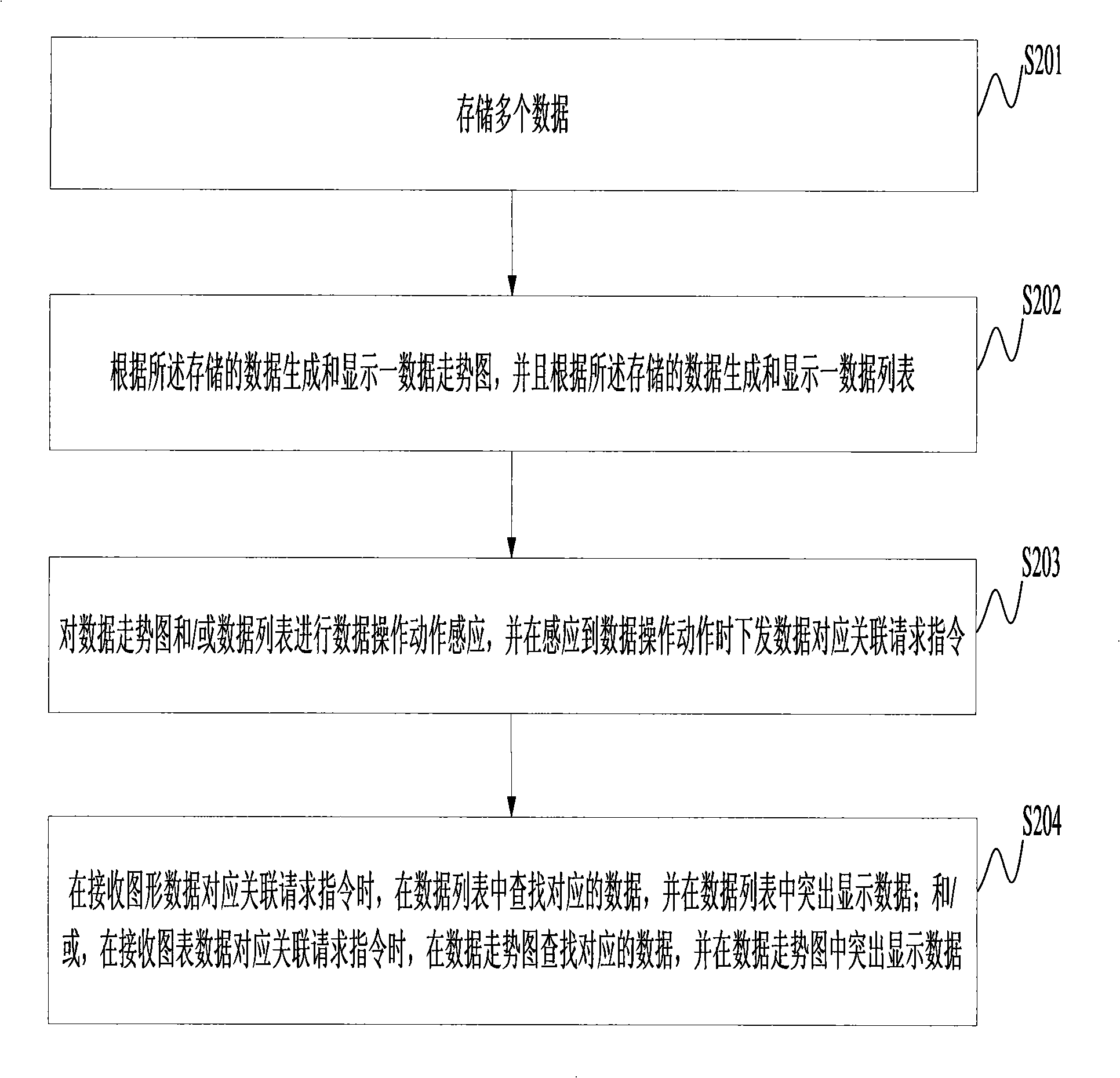

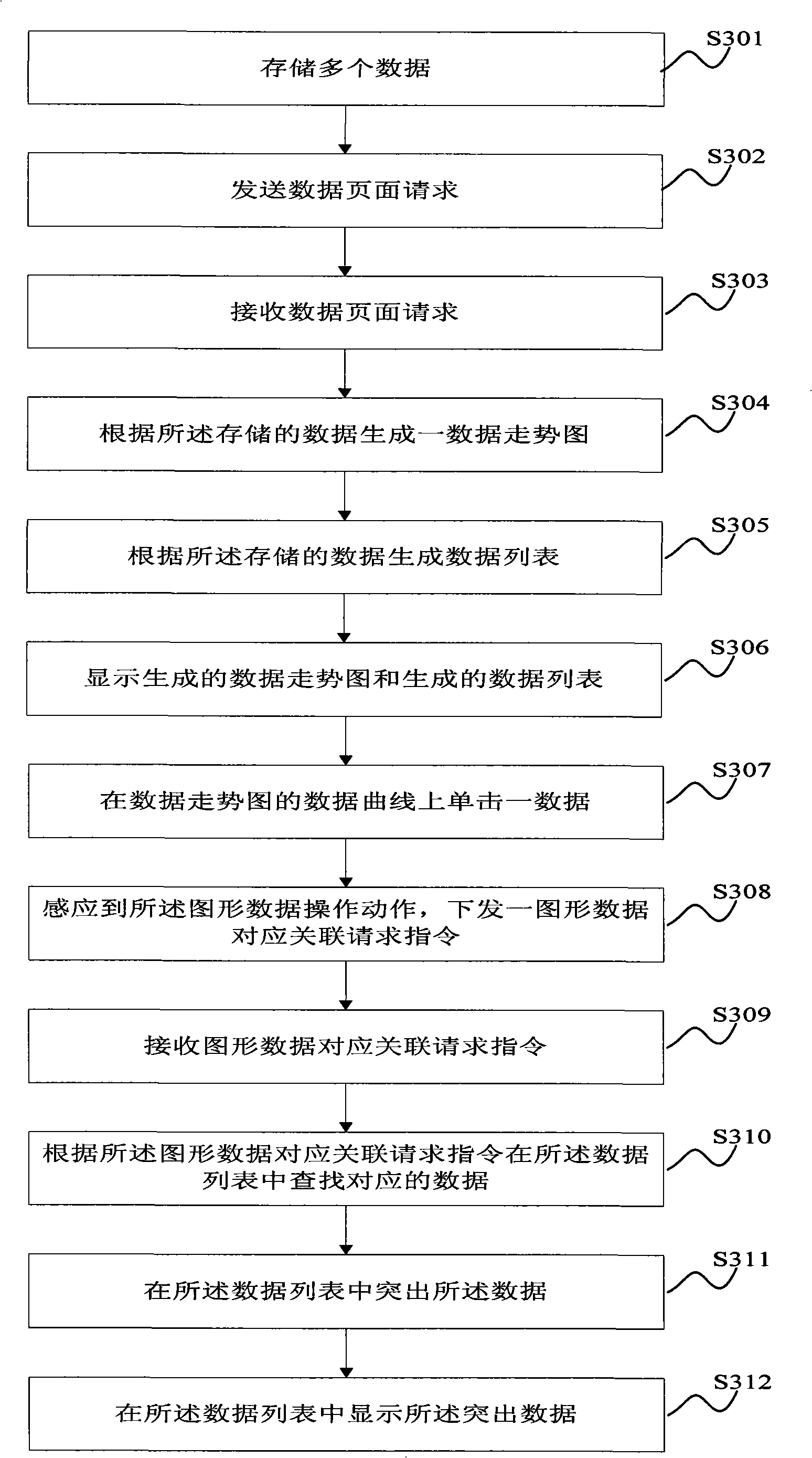

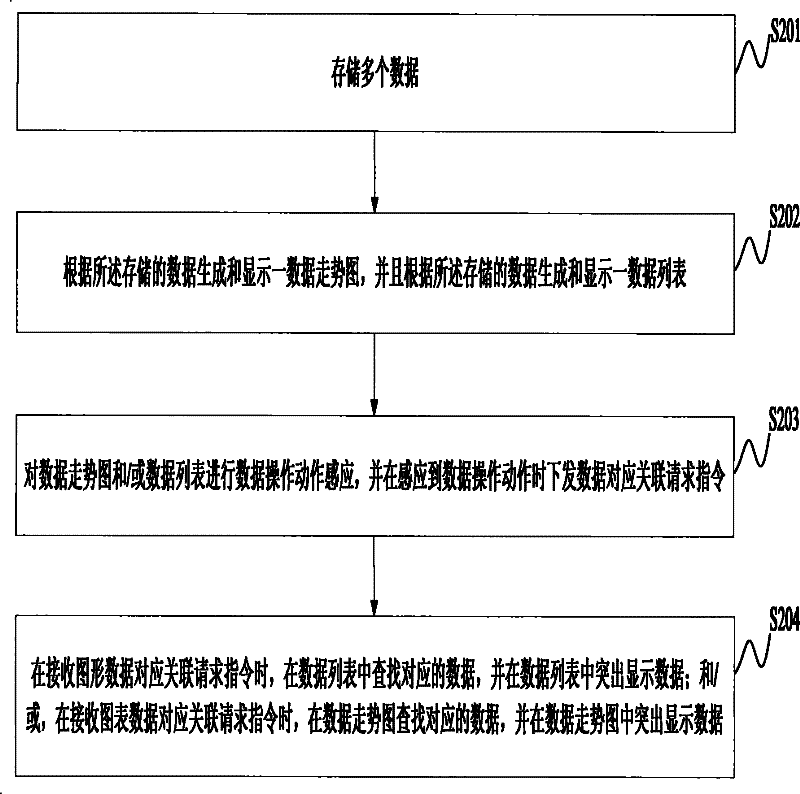

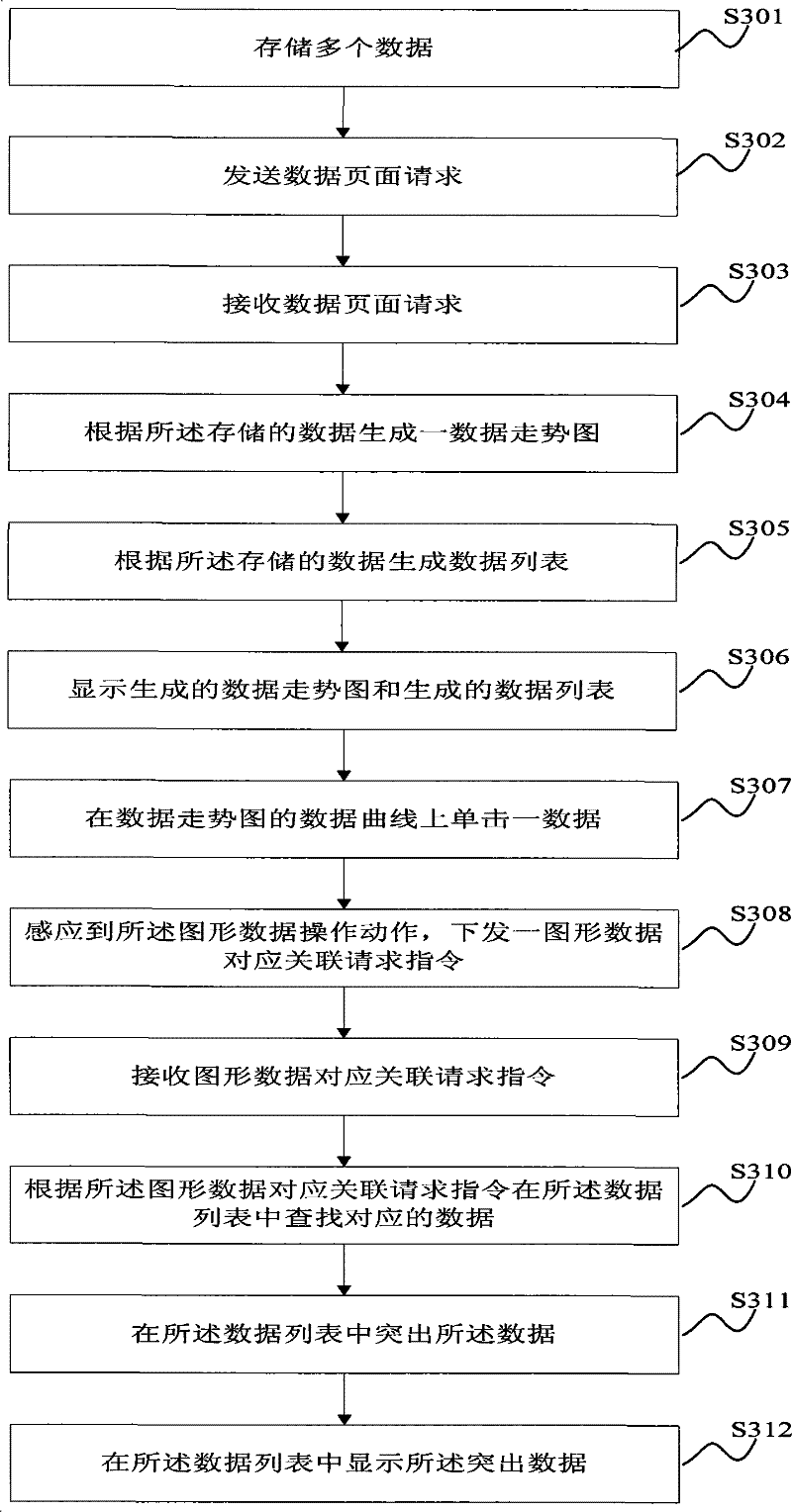

Data display system and display method

InactiveCN101339554AImprove experience valueIntuitive displaySpecial data processing applicationsGraphicsData display

Owner:刘宜云

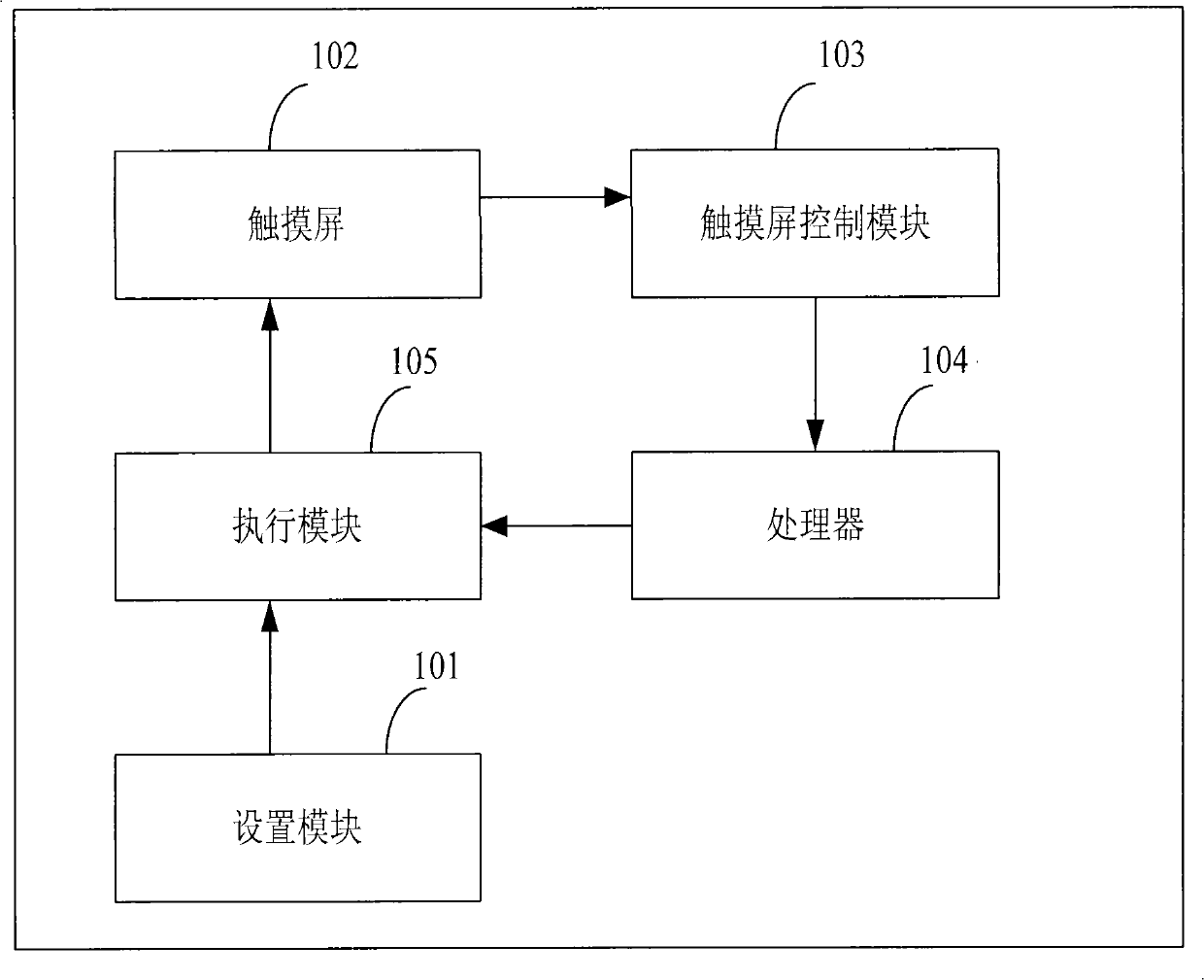

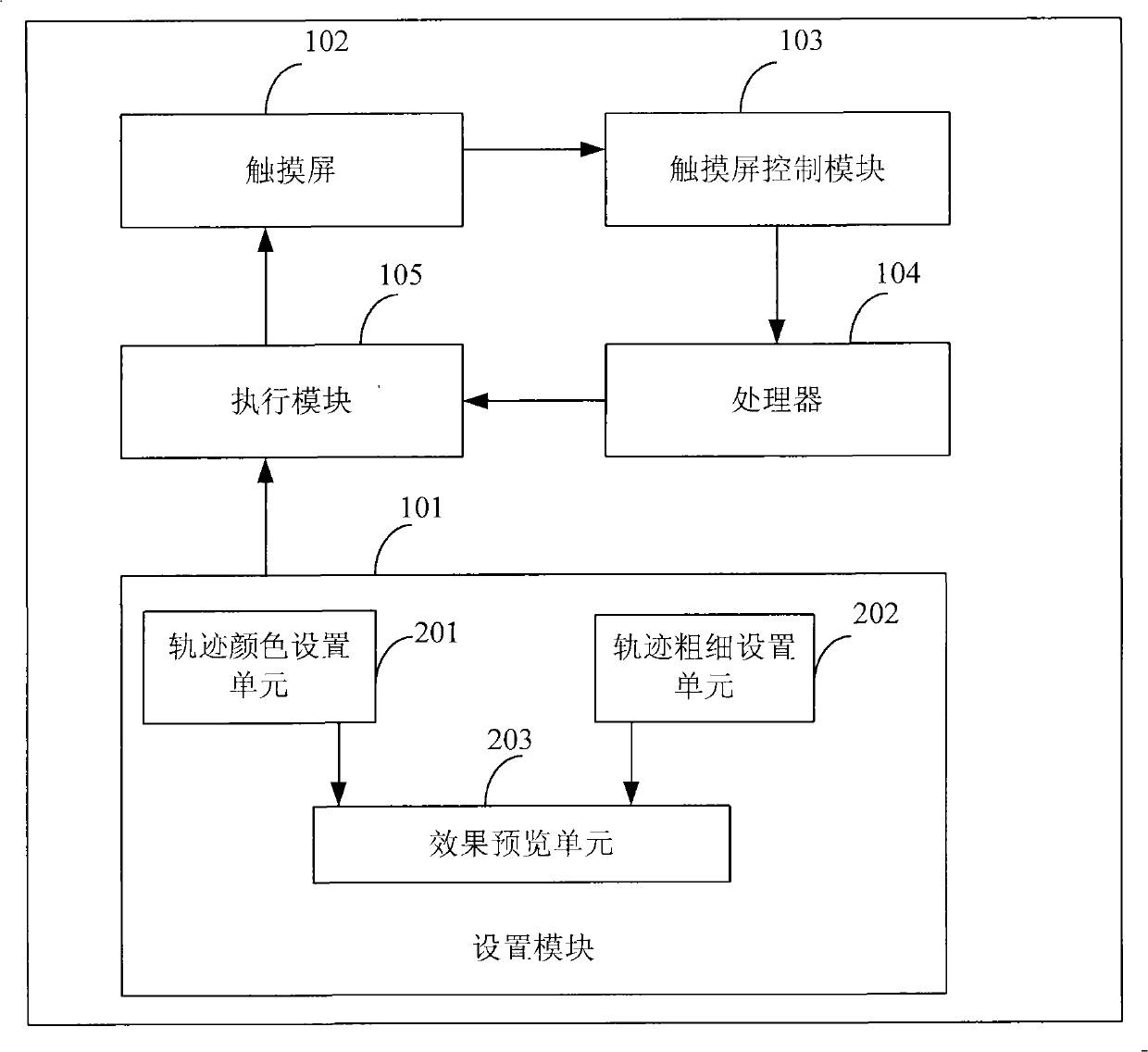

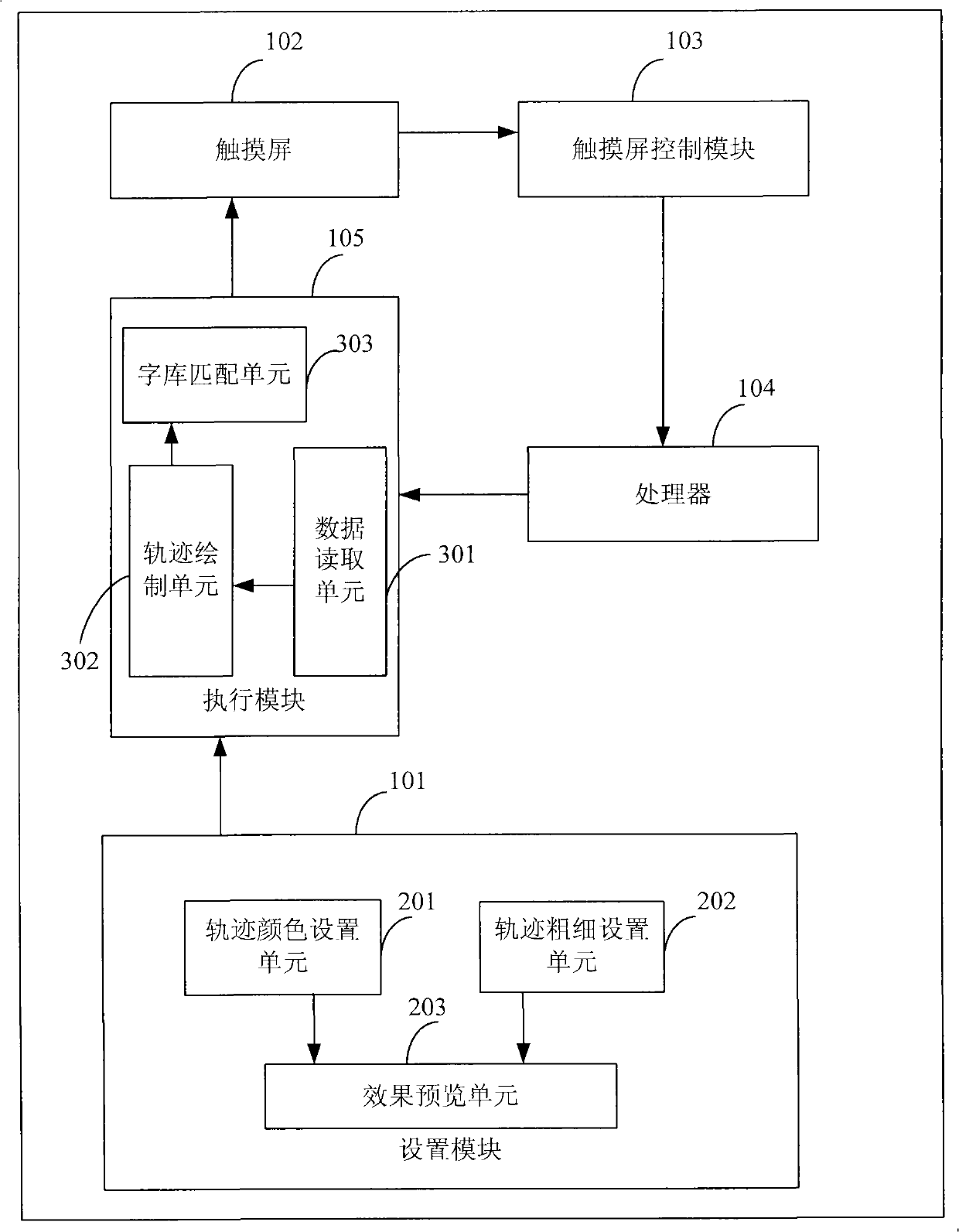

Hand input device capable of changing color and thickness of input trace and method thereof

InactiveCN101770343AIncrease diversityIncrease the colorfulnessInput/output processes for data processingChange colorGlyph

The present invention discloses a hand input device capable of changing the color and thickness of the input trace, which is characterized by comprising a touch screen, a set module, an execution module, a touch screen control module and a processor. The set module set the color and thickness of the hand input trace according to the favor of a user, the execution module reads the parameters of the color and thickness of the hand input trace set in advance, draws the hand input trace on the touch screen according to the parameters and the coordinate data of the touch point received, matches the hand input trace with the character stock and displays the similar character. By the device, the user can set the color and thickness of the input trace as required, thereby enhancing the experience of the user.

Owner:SHENZHEN COSHIP ELECTRONICS CO LTD

Intelligent distribution method

PendingCN110020827AIncrease costImprove distribution efficiencyBuying/selling/leasing transactionsLogisticsDistribution methodStudy methods

The invention discloses an intelligent distribution method. The method comprises the following steps: 1) a user places an order; 2) a commercial tenant delivers a meal; 3) whether an intelligent distribution condition is met or not is judged, and if so, an intelligent distribution mode is enabled; if not, a traditional order grabbing mode is enabled, wherein the intelligent distribution conditioncomprises a delivery area, a delivery number, a time period corresponding to a time attribute of the receiving time and a delivery time of the intelligent delivery mode; 4) according to a machine learning method, calculating the order receiving probability of the deliveryman by using the deliveryman information and the order information; and 5) carrying out global optimal matching according to theorder receiving probability of the deliveryman to determine a matching relationship between the order and the deliveryman, and distributing the order to the deliveryman with global optimal matching according to the matching relationship. The intelligent distribution method provided by the invention has the advantages of high efficiency, low cost, high client experience value and the like.

Owner:重庆淘创科技有限公司

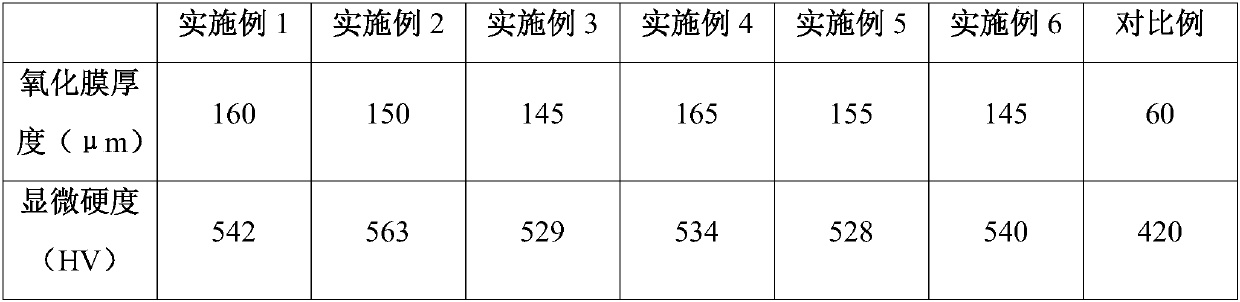

Aluminum alloy anode oxidation technology

The invention belongs to the technical field of metal surface treatment, and relates to an aluminum alloy anode oxidation technology. According to the technology, an aluminum alloy section is arrangedin an electrolytic bath loaded with oxidation electrolyte, so as to be electrolyzed; the electrolysis temperature is 10 to 30 DEG C; the aluminum alloy section is taken as an anode; a lead plate is taken as a cathode; an electrolysis mode is a direct current-alternating current overlapped method, so that an oxidation film is formed on the surface of the aluminum alloy section subjected to anode oxidation, the electrolysis speed is further improved through strict controlling of direct current-alternating current ratio, the deposition rate of the oxidation film is improved, an oxidation film with the thickness greater than 100 micrometers can be formed within 5min, the micro hardness of the obtained aluminum alloy section oxidation film is greatly improved, defects on the surface of the oxidation film are reduced, and the surface texture is denser.

Owner:CHINA ZHONGWANG

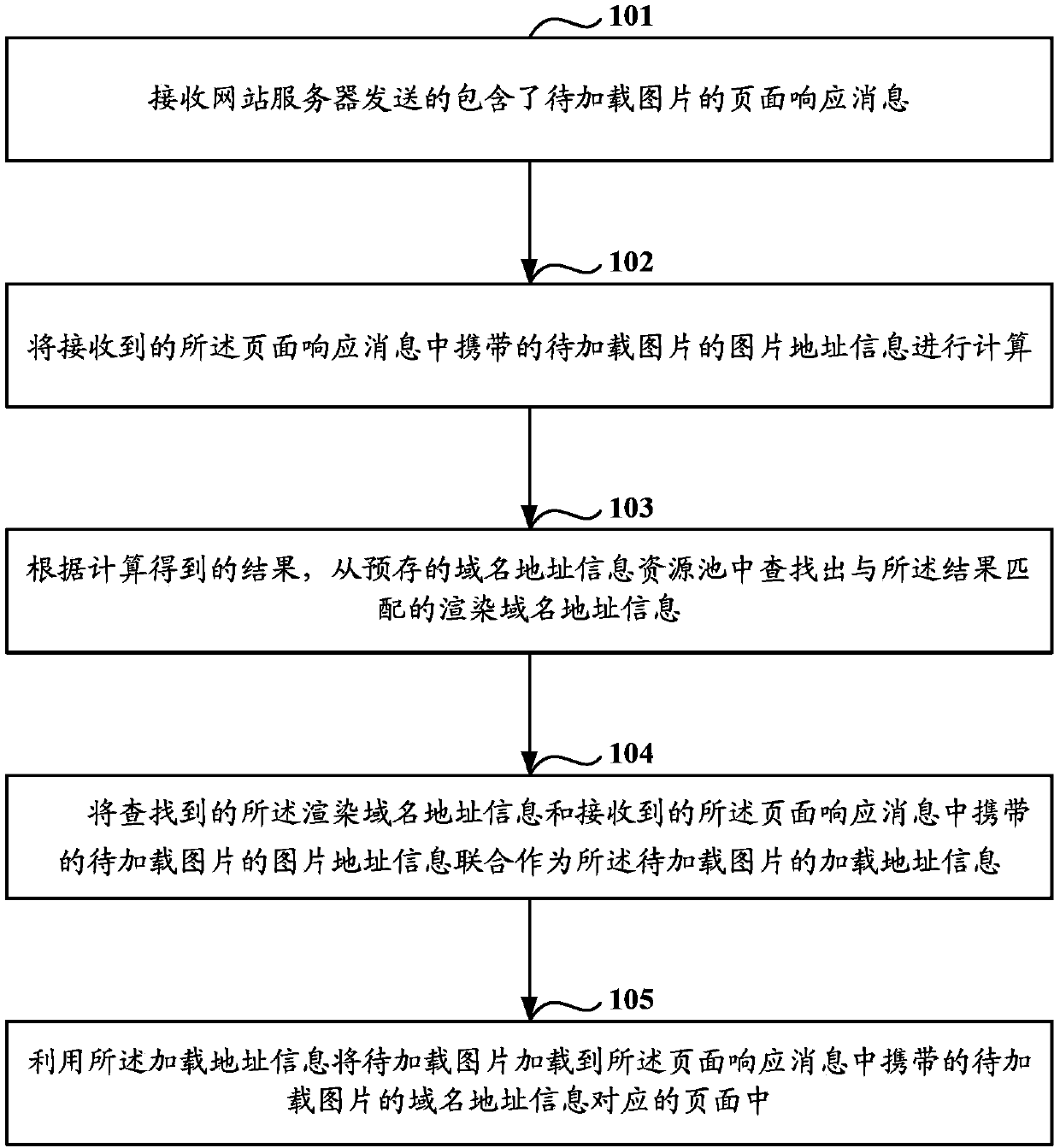

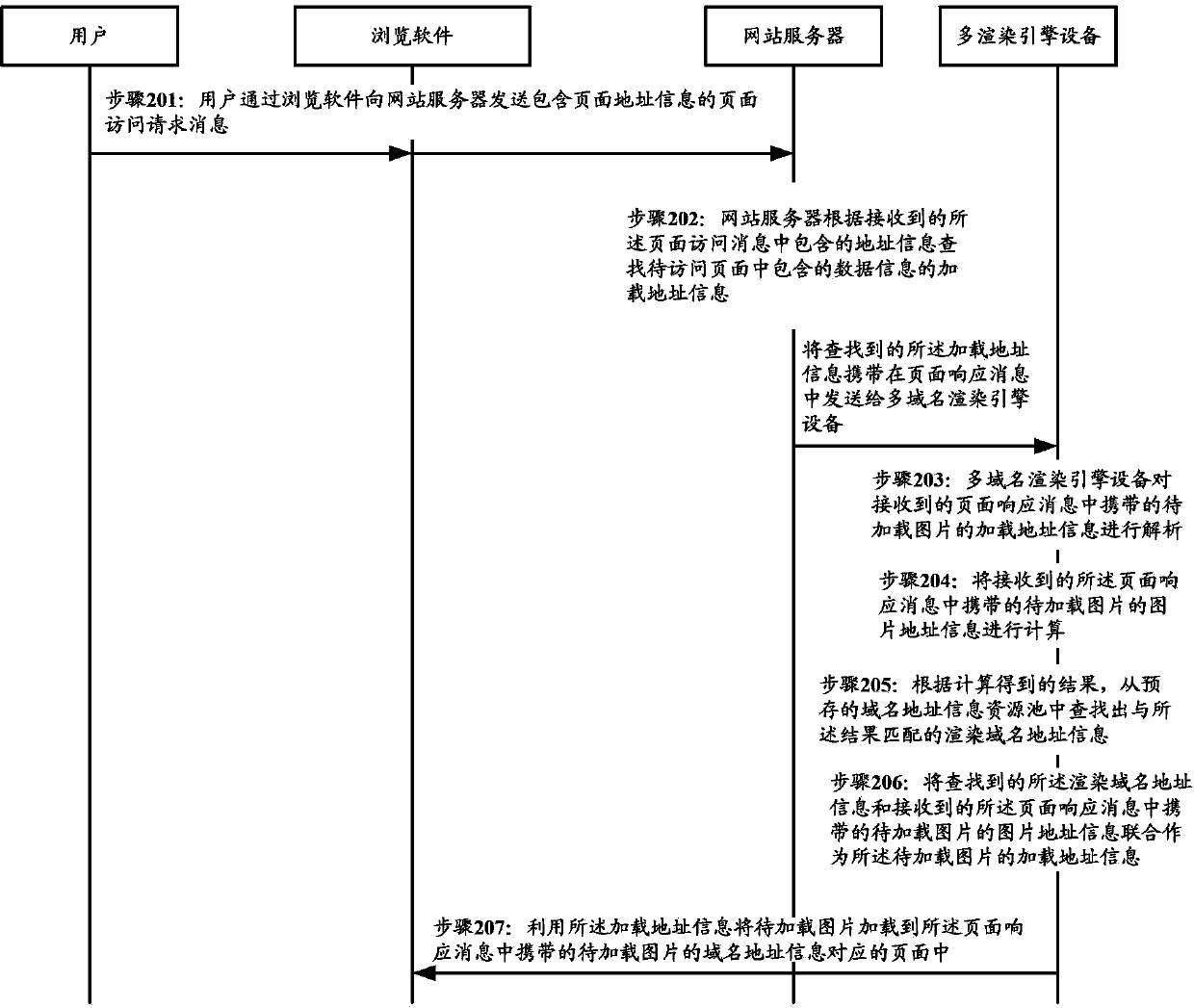

Method and equipment for loading image information

ActiveCN104182403AAvoid restrictions on the number of concurrent connectionsIncrease the number ofNetwork traffic/resource managementTransmissionInformation resourceResource pool

A page responding message including an image sent by a website server is received. Image address information of the image is calculated. Based on a result of the calculation, rendering domain name address information matching the result is searched from a pre-stored domain name address information resource pool. The searched rendering domain name address information and the image address information of the image included in the page responding message are combined as loading address information of the image. The image is loaded into a page corresponding to the domain name address information of the image included in the page responding message based on the loading address information of the image. The present techniques change the loading address information of the image with the same domain by loading address information with different domain names, thereby avoiding the limit to the number of parallel connections under the same domain name.

Owner:ALIBABA GRP HLDG LTD

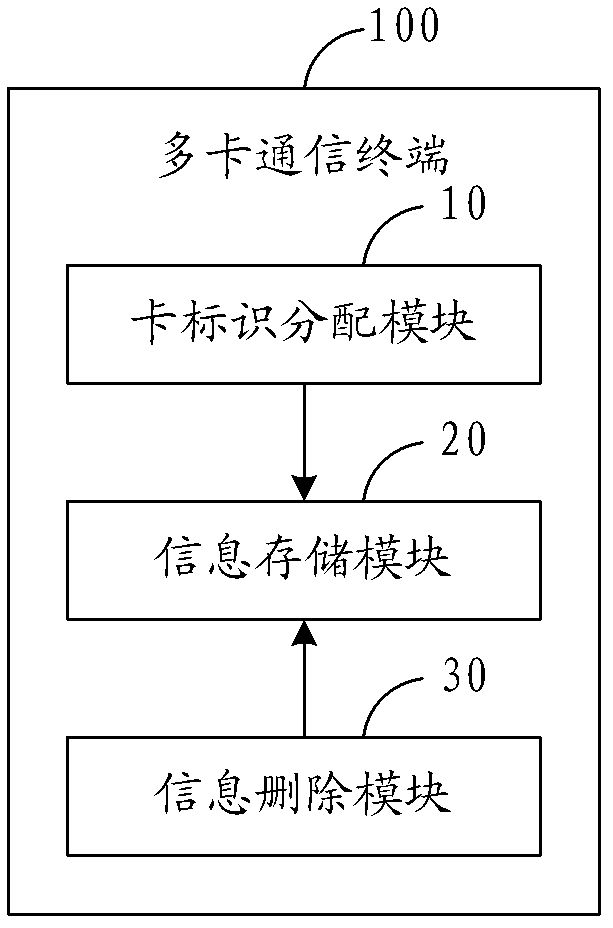

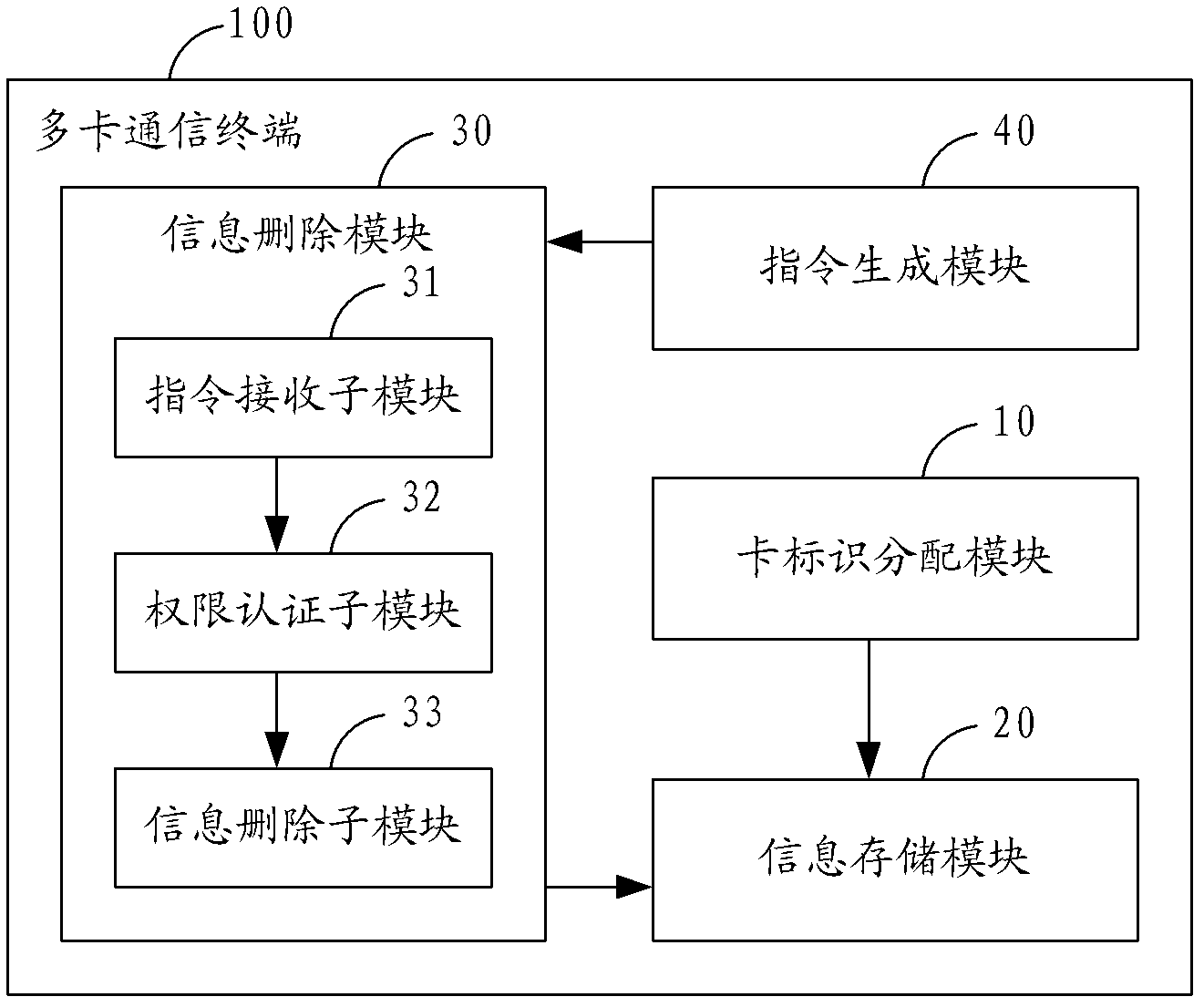

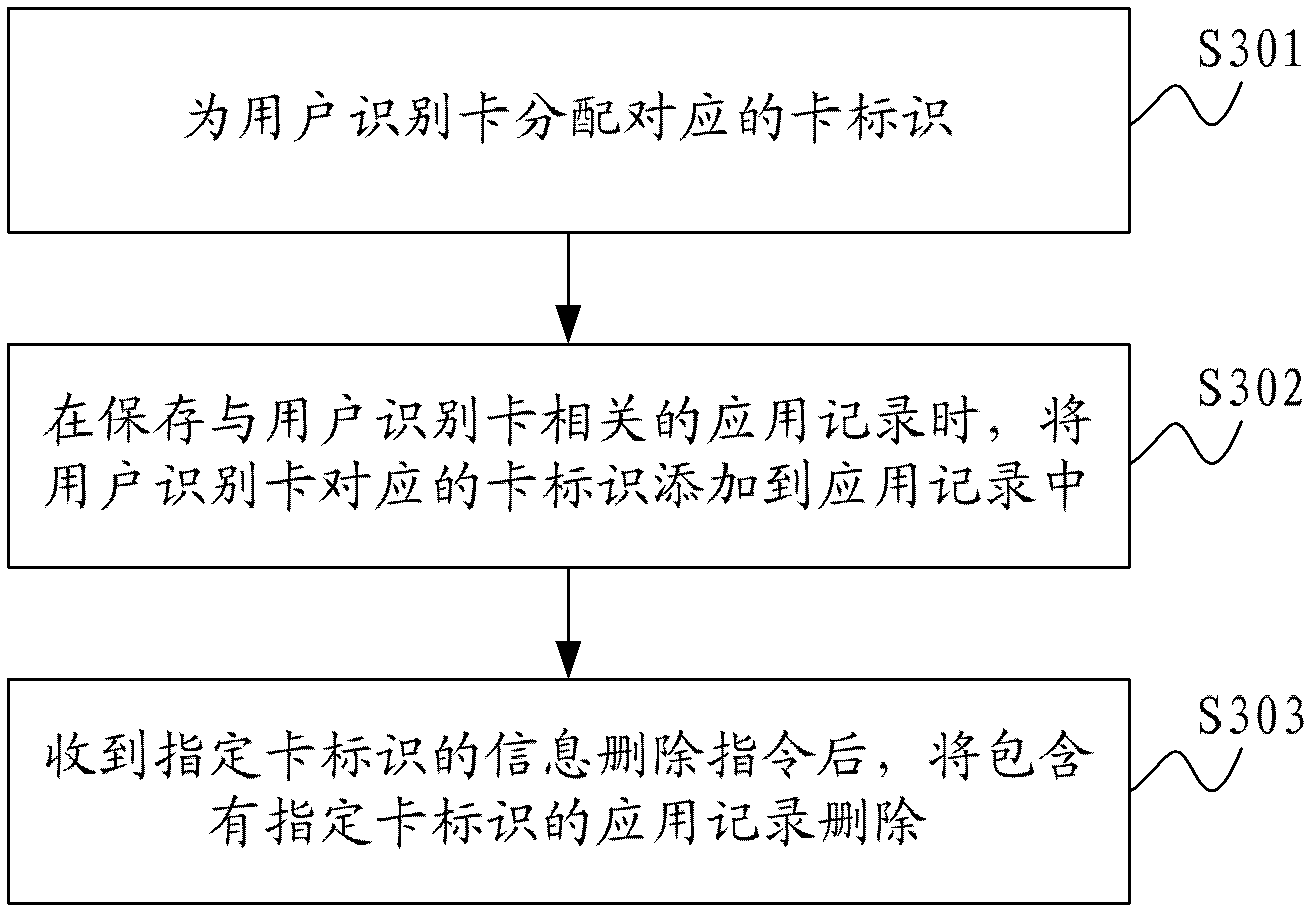

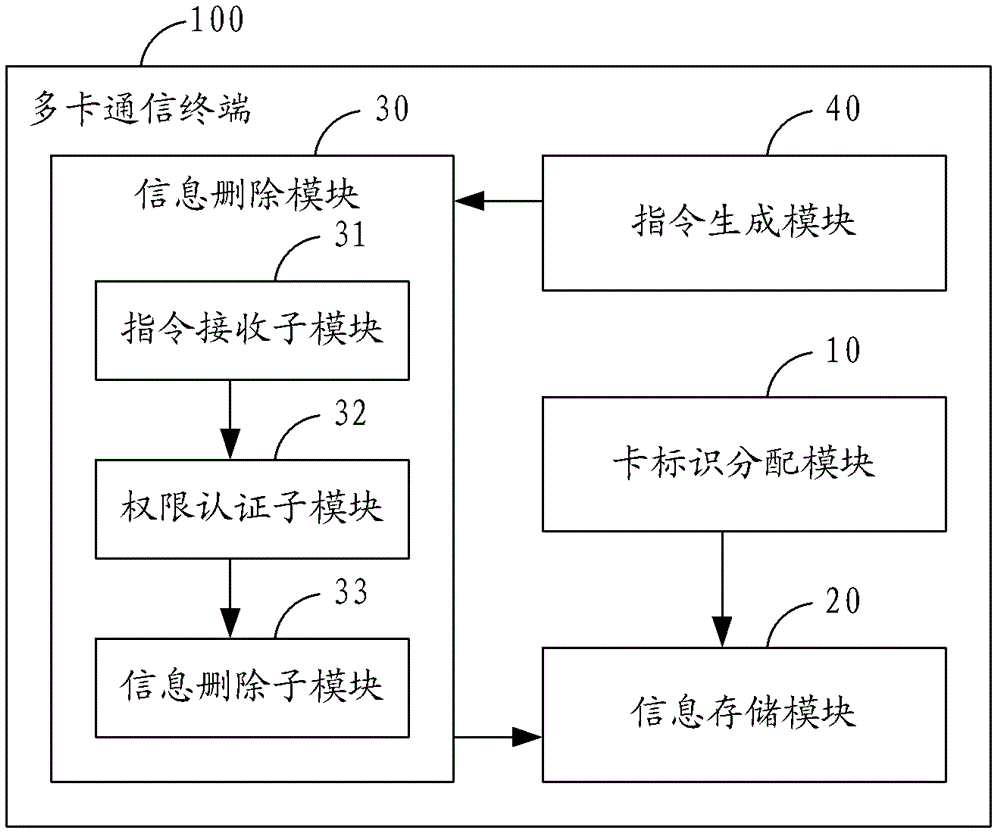

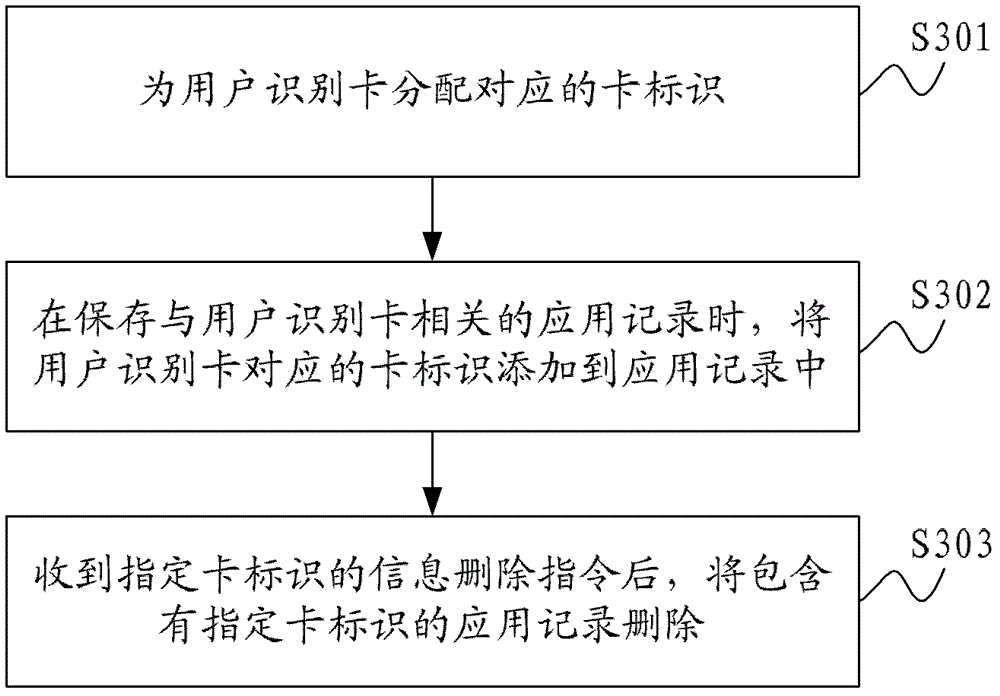

Information deleting method of multi-card communication terminal and multi-card communication terminal

The invention relates to the communication technology field and provides an information deleting method of a multi-card communication terminal. The information deleting method includes the steps of distributing corresponding card identification to a user identification card, adding the card identification corresponding to the user identification card to an application record when the application record relevant to the user identification card is stored, and deleting the application record including the designated card identification after an information deleting command of the designated card identification is received. Accordingly, the invention further provides the multi-card communication terminal. The information deleting method of the multi-card communication terminal and the multi-card communication terminal has the advantages of conveniently and quickly deleting the history application record of the user identification card designated by a user.

Owner:YULONG COMPUTER TELECOMM SCI (SHENZHEN) CO LTD

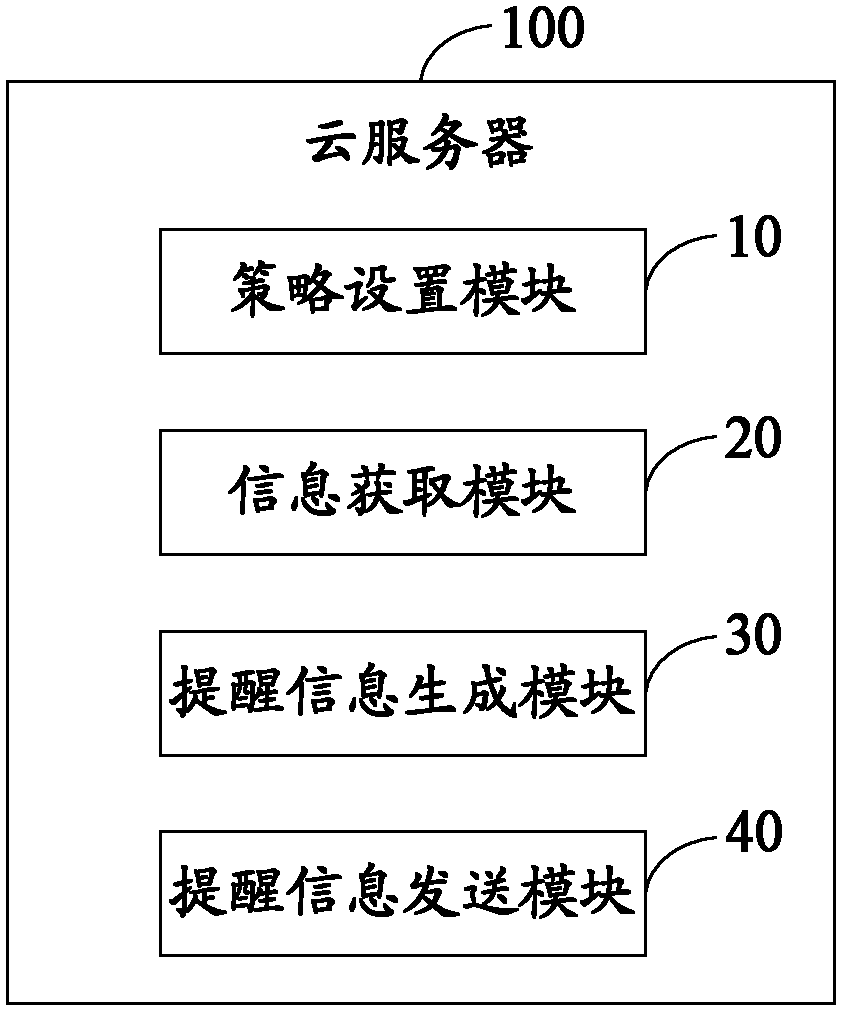

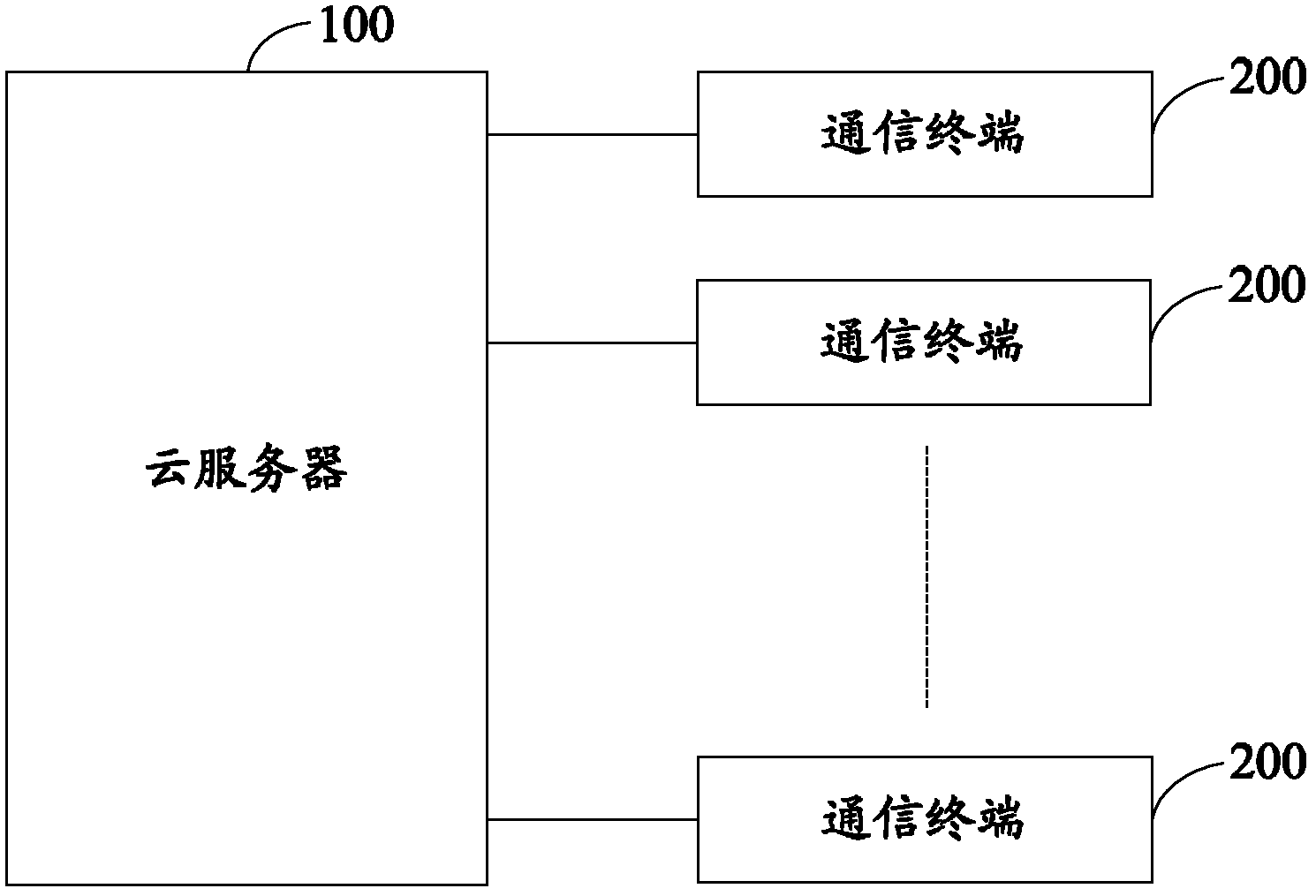

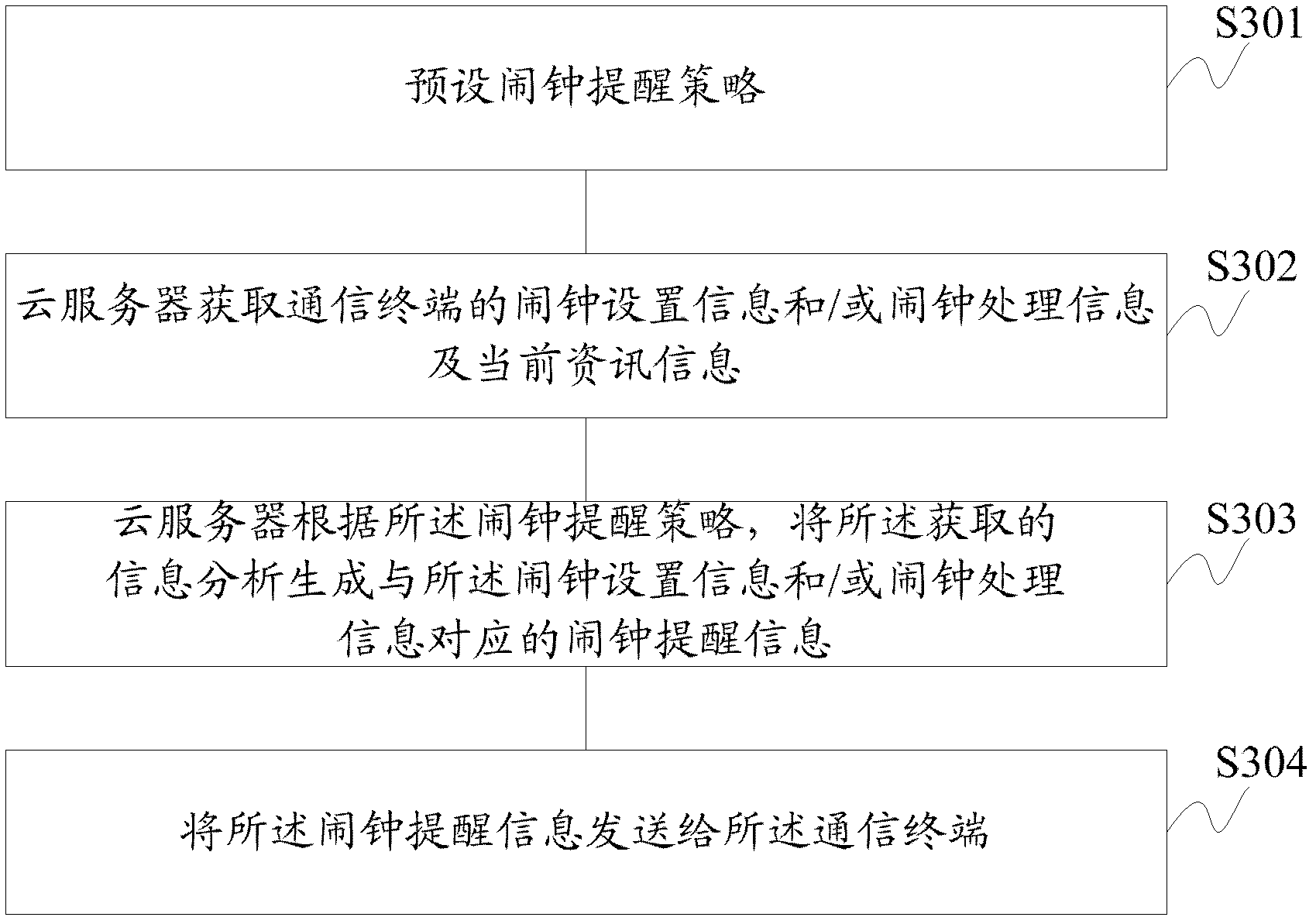

Cloud server-based alarm clock reminding method and cloud server

ActiveCN102413416BImprove experience valueSubstation equipmentWireless commuication servicesComputer terminalAlarm clock

The invention is applicable to the field of communication technology, and provides a cloud server-based alarm clock reminding method. The method comprises the steps of setting a strategy: presetting an alarm clock reminding strategy; obtaining information: obtaining alarm clock setting information and / or alarm clock treating information and current message information of a communication terminal; generating reminding information: generating alarm clock reminding information which corresponds to the alarm clock setting information and / or the alarm clock treating information by analyzing the obtained information; and transmitting the reminding information: transmitting the alarm clock reminding information to the communication terminal. Therefore, the alarm sound can be interesting, and the experience of a user to a terminal can be improved.

Owner:YULONG COMPUTER TELECOMM SCI (SHENZHEN) CO LTD

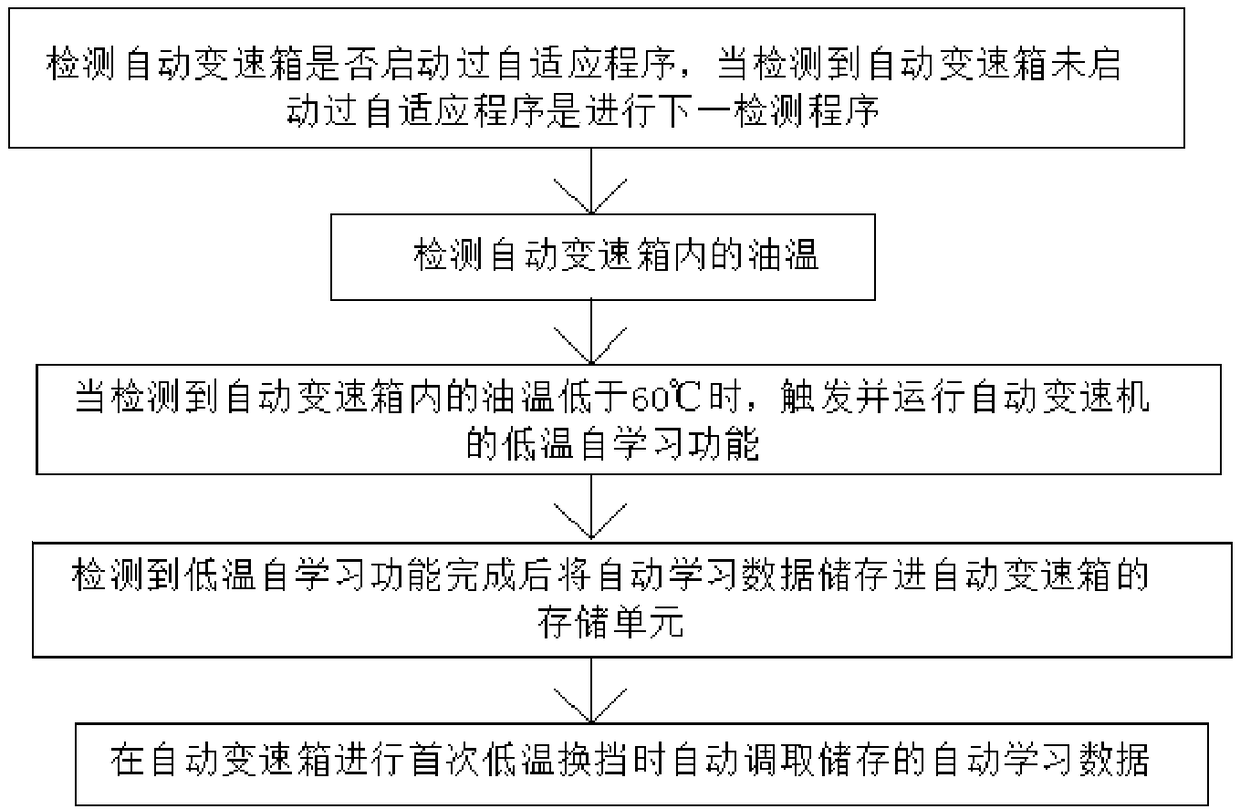

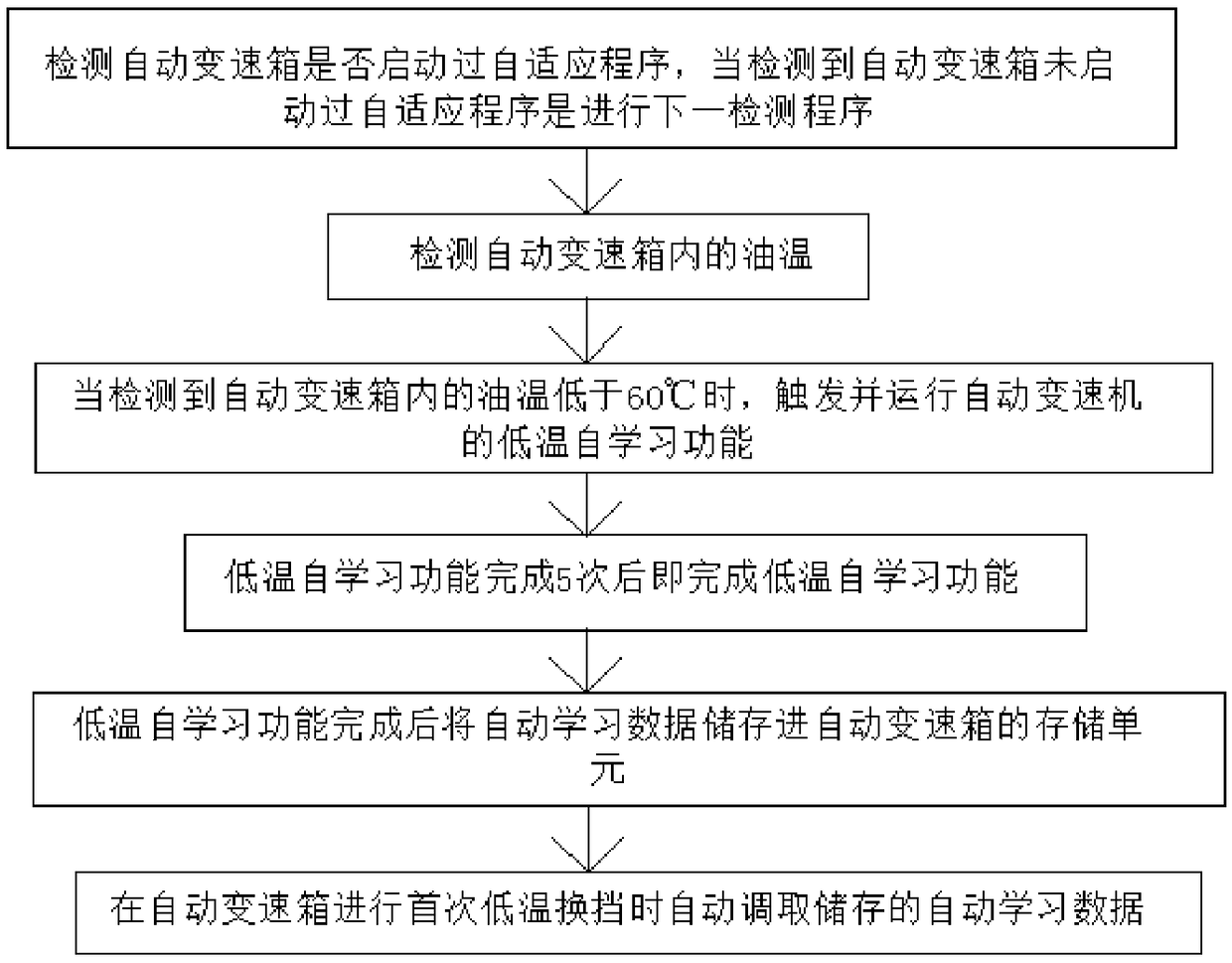

Low-temperature self-study method of automatic gearbox and automatic gearbox

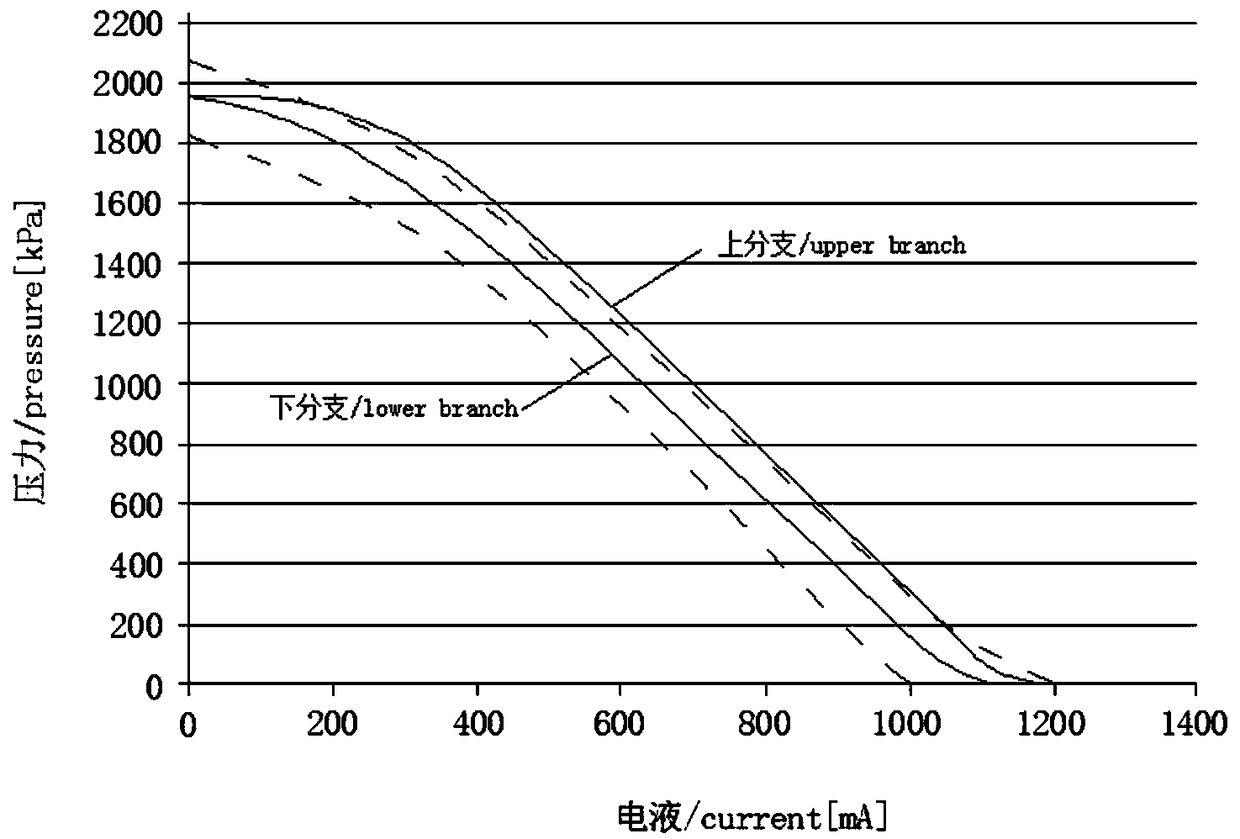

InactiveCN108869720AImprove shift qualityShift Quality AssuranceGearing controlAutomobile marketSelf adaptive

The invention relates to a low-temperature self-study method of an automatic gearbox and the automatic gearbox. According to the low-temperature self-study method of the automatic gearbox, a fast adaptive function of the automatic gearbox at low temperature is added and is only triggered for one time during the whole life cycle of the automatic gearbox; the function is triggered by two conditions:(1) the oil temperature in the automatic gearbox is lower than 60 DEG C, and (2) the automatic gearbox is not subjected to an adaptive program at the normal oil temperature interval ranging from 60 DEG C to 105 DEG C, so that after a finished automobile is started at low temperature for the first time, a low-temperature self-study function of an electronic control unit in the automatic gearbox istriggered at the time; after the low-temperature self-study function is carried out for 5 times, the program can be forced to quit, so that the gear shifting quality of the automobile is favorable, and the automatic gearbox has no need to self-adapt; and meanwhile, automatic study data is stored in a storage unit of the automatic gearbox, so that the stored automatic study data can be automatically retrieved for later low-temperature gear shifting in the automobile market.

Owner:SHENGRUI TRANSMISSION

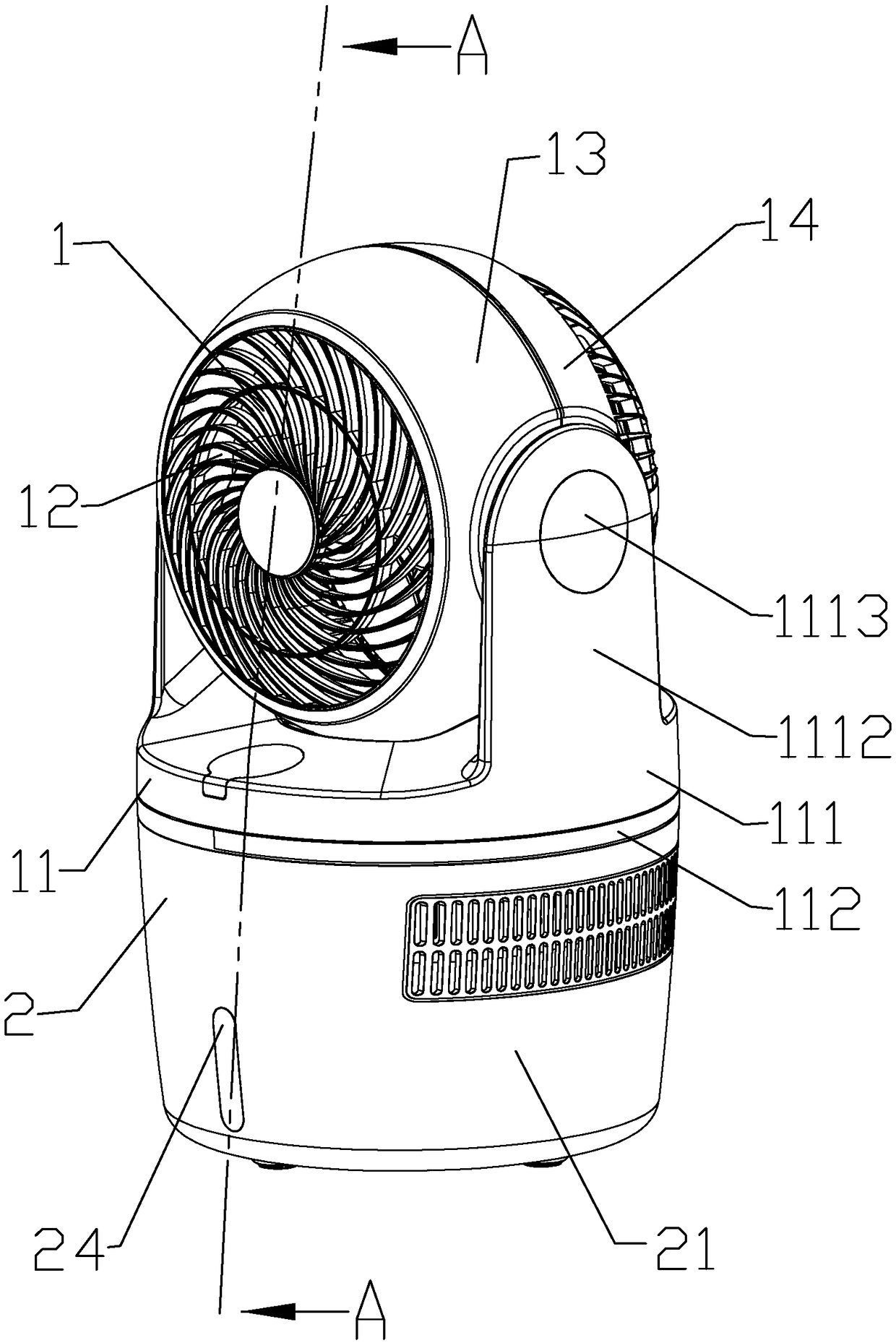

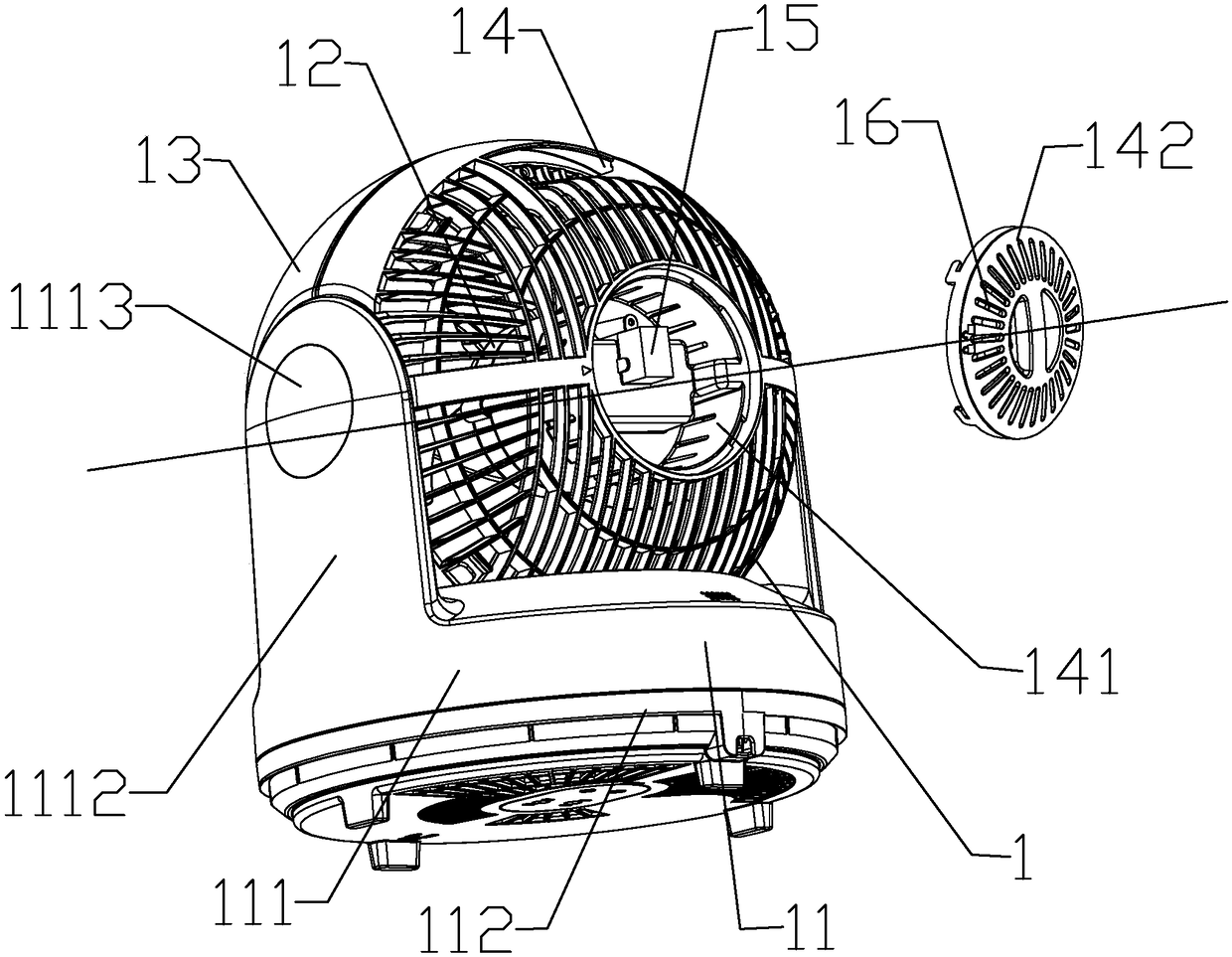

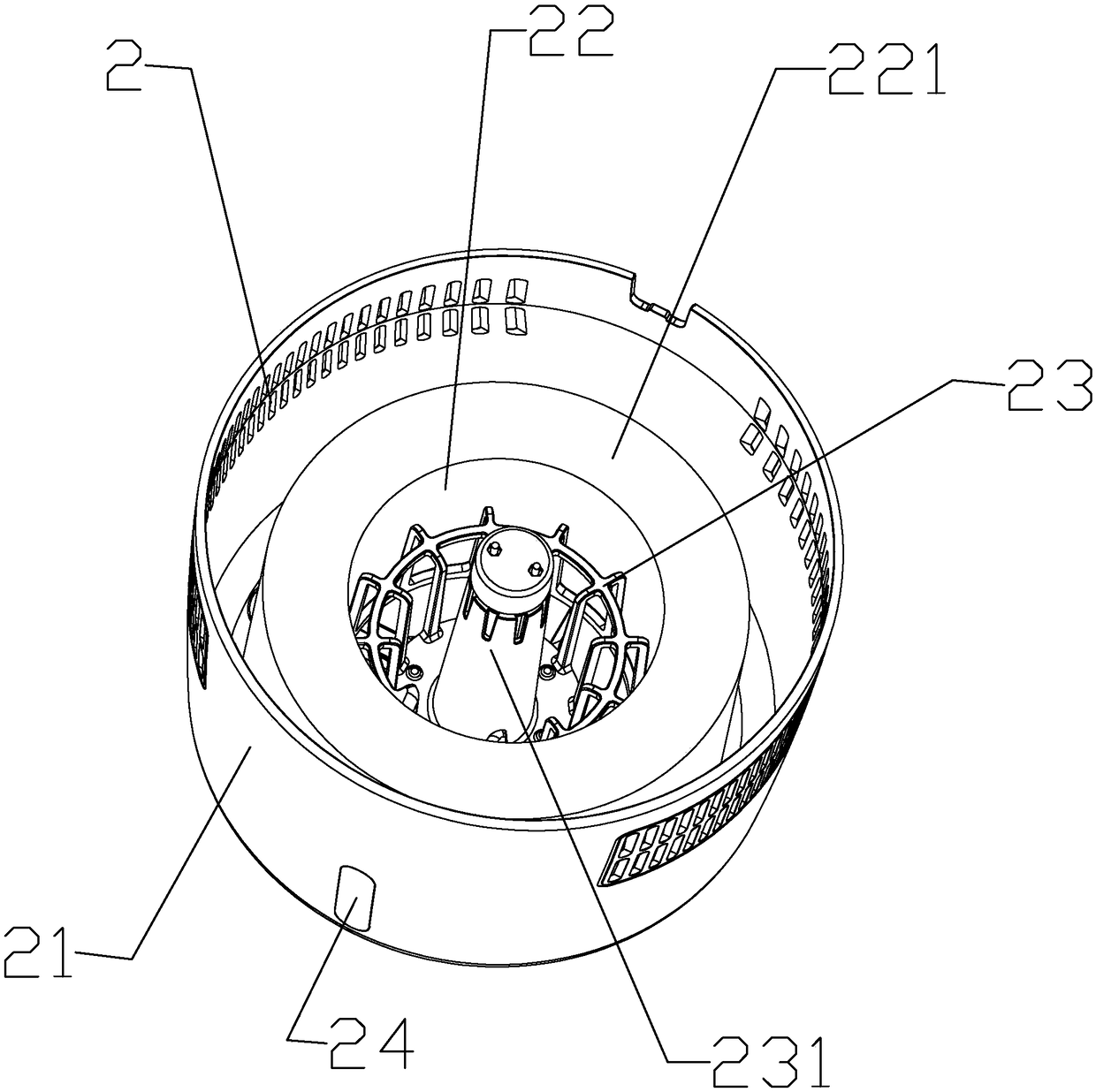

Air circulation fan with water cooling humidifying function

PendingCN108444016APrevent drynessLower purchase costLighting and heating apparatusFree-cooling systemsAir cyclePulp and paper industry

The invention discloses an air circulation fan with the water cooling humidifying function. The air circulation fan comprises a fan head and a machine body, the fan head is arranged on the machine body, the fan head comprises a machine base and a draught fan assembly used for providing air circulation power, the draught fan assembly is arranged on the machine base, the machine base is arranged onthe machine body, the machine body comprises a water groove used for containing water and a volatilizer used for volatilizing water in the water groove, the volatilizer is arranged at the bottom of the water groove, multiple air inlets are formed in the side wall of the water groove, and multiple water steam outlets are formed in the bottom of the machine base, and are formed in the upper portionof the volatilizer. The air circulation fan utilizes circular air to drive water to volatilize, the circular air is used for spreading volatilizing water steam to the air, the phenomenon that the aircirculation fan is independently used, water in the air is lost, and air is dry is avoided, wind is combined with water mist to flow, reduction of indoor temperature is accelerated, the fan has multiple purposes, purchasing cost of a consumer is saved, use energy consumption is reduced, and the experience value of the consumer is increased.

Owner:佛山乾合科迈电器有限公司

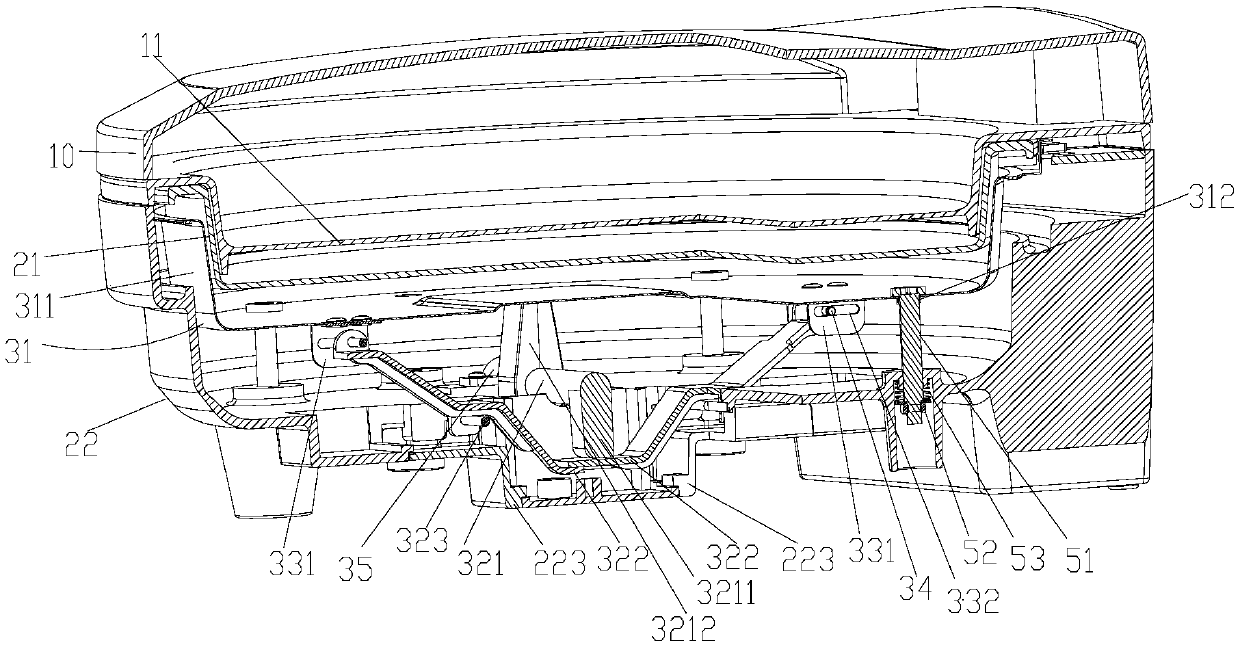

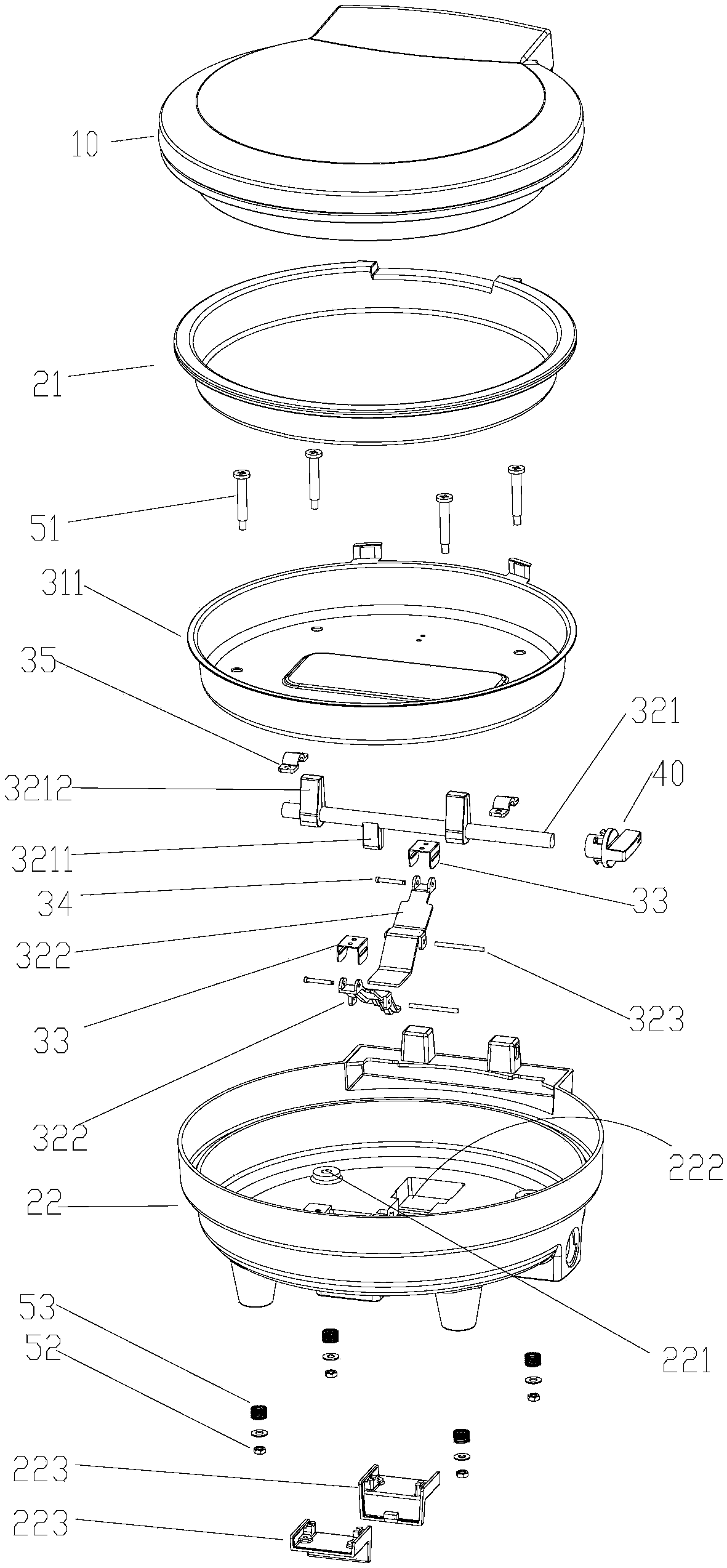

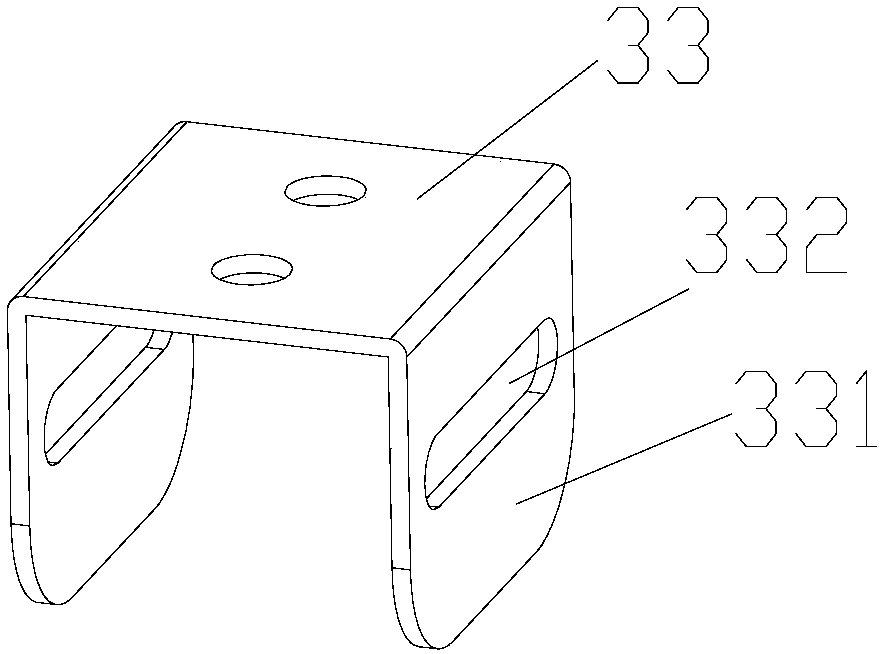

Baking machine

ActiveCN107661030AImprove experience valueEasy to operateRoasters/grillsFrying pansEngineeringMechanical engineering

The invention provides a baking machine which comprises a baking tray assembly and a lifting adjusting assembly. The baking tray assembly comprises a base and a baking tray arranged on the base. The lifting adjusting assembly comprises a gear shaft, an upwarp plate and a supporting part. The gear shaft is rotationally installed on the base and provided with a first protruding block which protrudesout of the outer surface of the gear shaft. The upwarp plate is supported on the base through the supporting part and can rotate around the supporting plate. The upwarp plate is provided with two ends arranged on the two sides of the supporting part respectively. The first end of the upwarp plate abuts against the bottom of the baking tray. When the gear shaft is rotated, the first protruding block can make contact with or be separated from the second end of the upwarp plate to drive the first end of the upwarp plate to rise or fall. A user only needs to rotate the gear shaft when adjusting the height of the baking tray, and the baking machine is simple and convenient to operate and high in user experience value.

Owner:ZHEJIANG SUPOR ELECTRICAL APPLIANCES MFG CO LTD

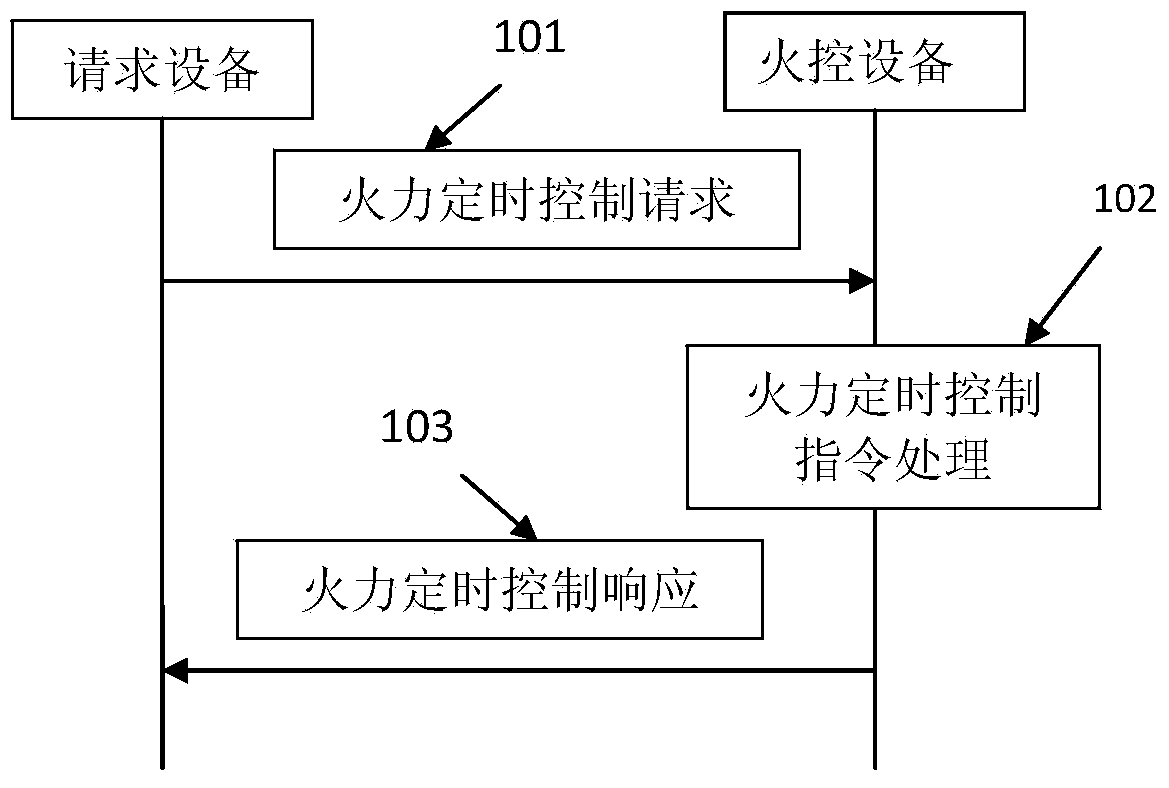

Firepower timing control method, device and system

InactiveCN103809553AReduce the rate of manual interventionImprove experience valueProgramme total factory controlTime informationFire control

The invention relates to intelligent electrical household appliances and aims at solving the problem that a user cannot perform firepower timing control on a fire control device through request devices such as intelligent terminals. The firepower timing control method comprises the following steps that a fire control device receives a firepower timing control request message sent by a request device or a request user, wherein the firepower timing control request message comprises at least one firepower timing control instruction which comprises kitchen range identification information, timing time information and firepower instruction information; the fire control device adjusts a firepower of a kitchen range specified by the kitchen range identification information into a firepower specified by the firepower instruction information in a time period specified by the timing time information according to the firepower timing control instruction. The invention further provides the fire control device for fire timing control, the request device for firepower timing control and a firepower timing control system. The firepower timing control method, the fire control device for fire timing control, the request device for firepower timing control and the firepower timing control system are applicable to firepower timing control.

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

Method for anodizing surface of high corrosion-resistant aluminum profile

ActiveCN112095132AImprove corrosion resistanceHigh hardnessAnodisationDipotassium phosphatePhosphoric acid

The invention relates to a method for anodizing the surface of a high corrosion-resistant aluminum profile. The method particularly comprises four steps of degreasing, oxidation, modification and electroplating, specifically, an anodizing solution is a mixed solution of pyruvic acid, sulfuric acid, ANODAL EE solution additive, dipotassium hydrogen phosphate, monopotassium phosphate, aluminum sulfate, artificial plasma and deionized water. According to the anodizing method, firstly, the surface of the aluminum alloy is degreased by using a degreaser, an oxide film on the surface is removed by dilute acid, then the surface of the aluminum alloy is oxidized to form an oxide film by means of the matching of anodic oxidation and cathodic electroplating, and a high corrosion-resistant chromium film is electroplated on the outer layer of the oxide film, so that the corrosion-resistant performance of the surface of the aluminum alloy is remarkably improved, and the surface of the aluminum alloy is modified; and compared with a common anodic oxidation process, the oxide film is higher in hardness, more resistant to scratching, impact and abrasion, higher in corrosion resistance, and capableof improving customer experience value, and the method has excellent practicability and creativity, high market value and wide application prospects.

Owner:池州市安安新材科技有限公司

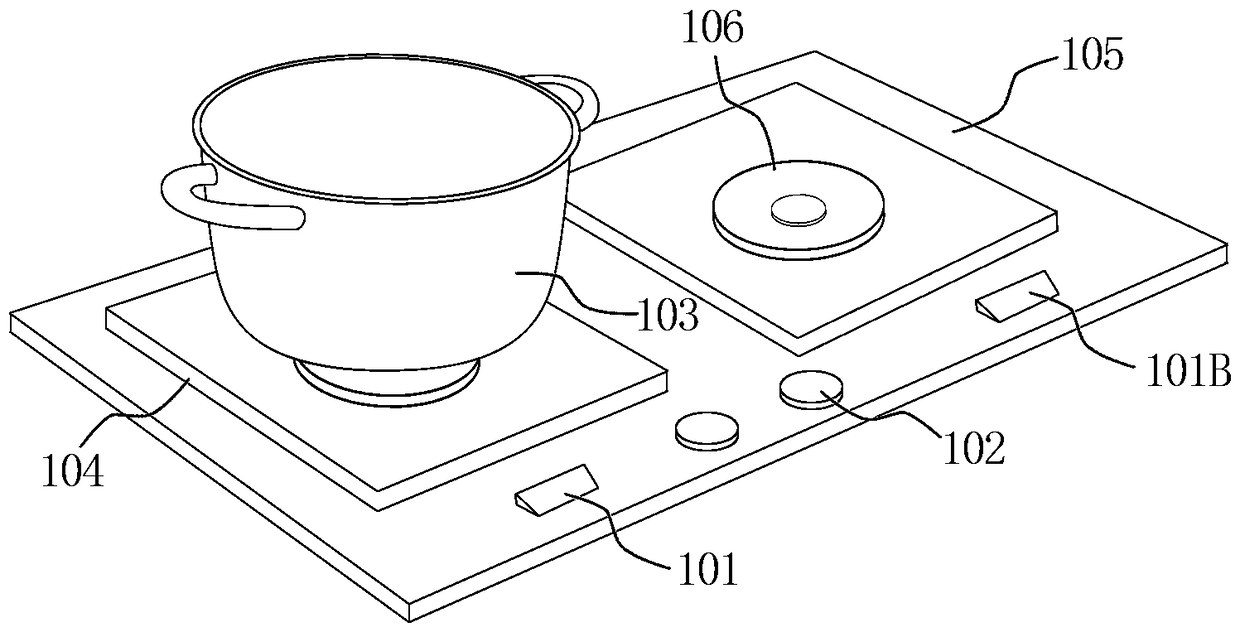

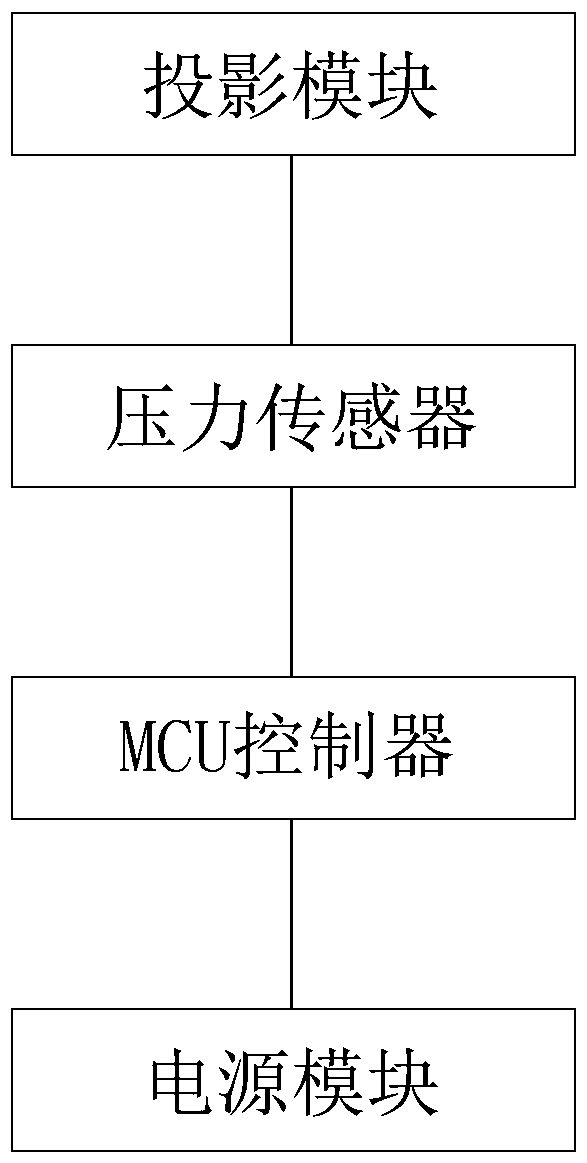

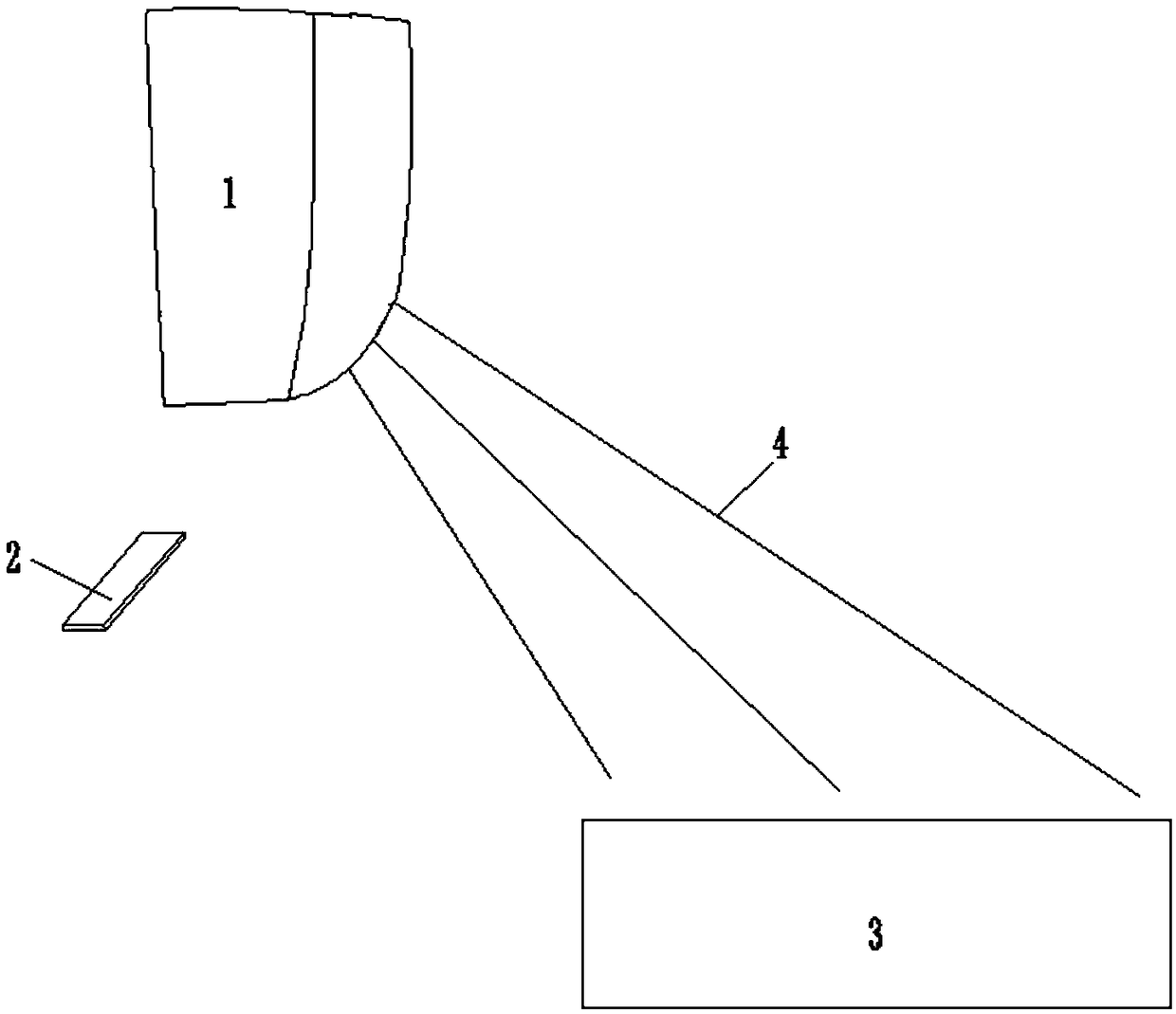

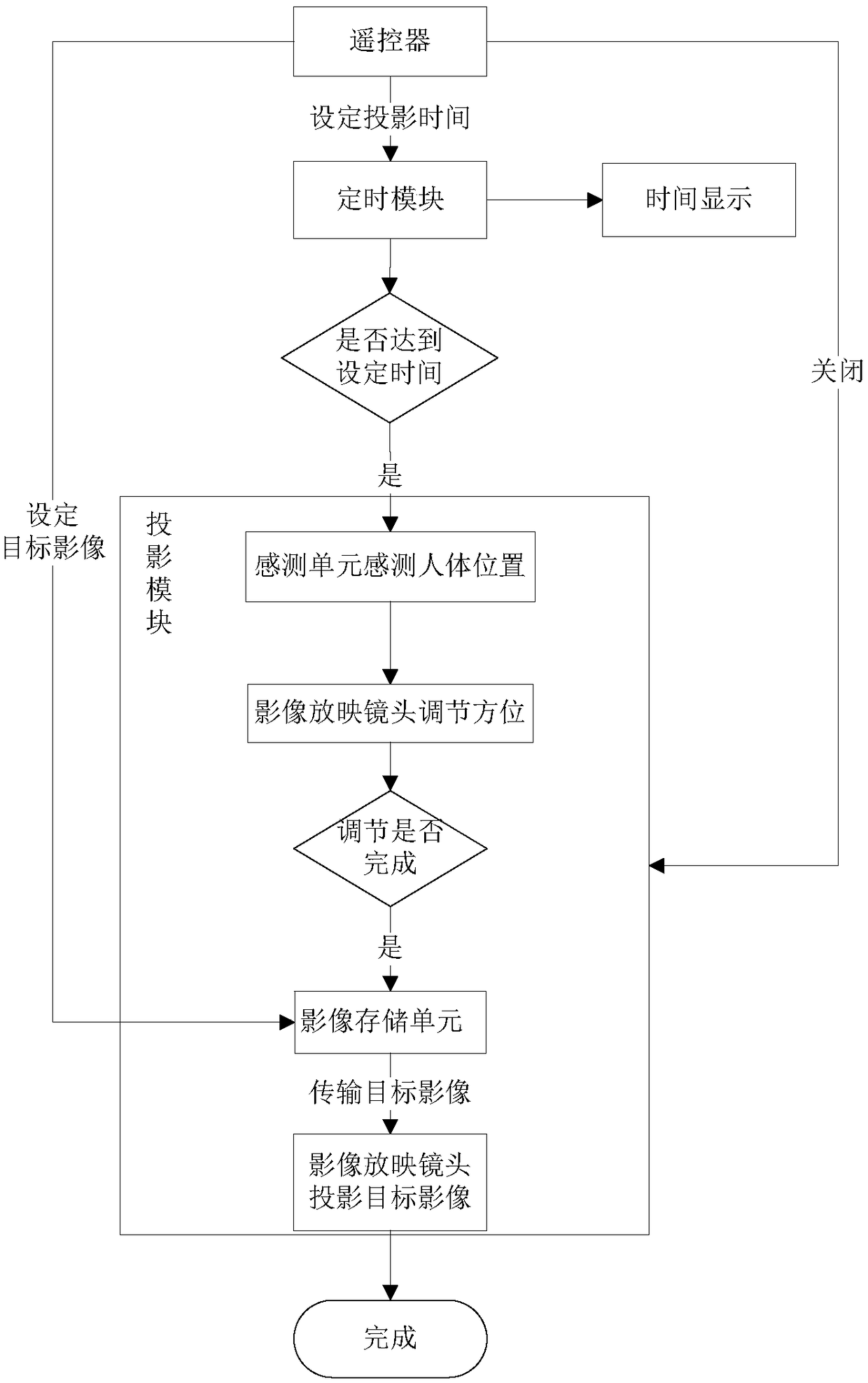

Intelligent projection gas stove and implementation method thereof

PendingCN108151078AImprove experience valueImprove experienceDomestic stoves or rangesLighting and heating apparatusTime informationComputer module

The invention discloses an implementation method of an intelligent projection gas stove. Sampling data further comprise temperature information and cooking method information. The implementation method is characterized in that a projection module is designed in the gas stove, a pressure sensor is arranged below a gas stove pot support, early-stage sampling data are set, and the sampling data are made into an algorithm and recorded into an MCU controller of the gas stove. The sampling data comprise different weight data and time data of cooking different kinds of food in different pots. Meanwhile, the pressure sensor has a self-adaptive algorithm, and can carry out automatic recognition according to the user habitual cooking dishes and the weight of a pot, when the pot is placed on the gasstove, the gas stove projection module automatically projects the information to the side face of a pot body on the pot support, and specifically projects the information such as time information ofcooking, countdown information, temperature information and cooking method information, a user can visually see the information on the pot, the virtuality and the reality are combined, and the user experience value is improved.

Owner:泉州市雍和智能科技有限公司

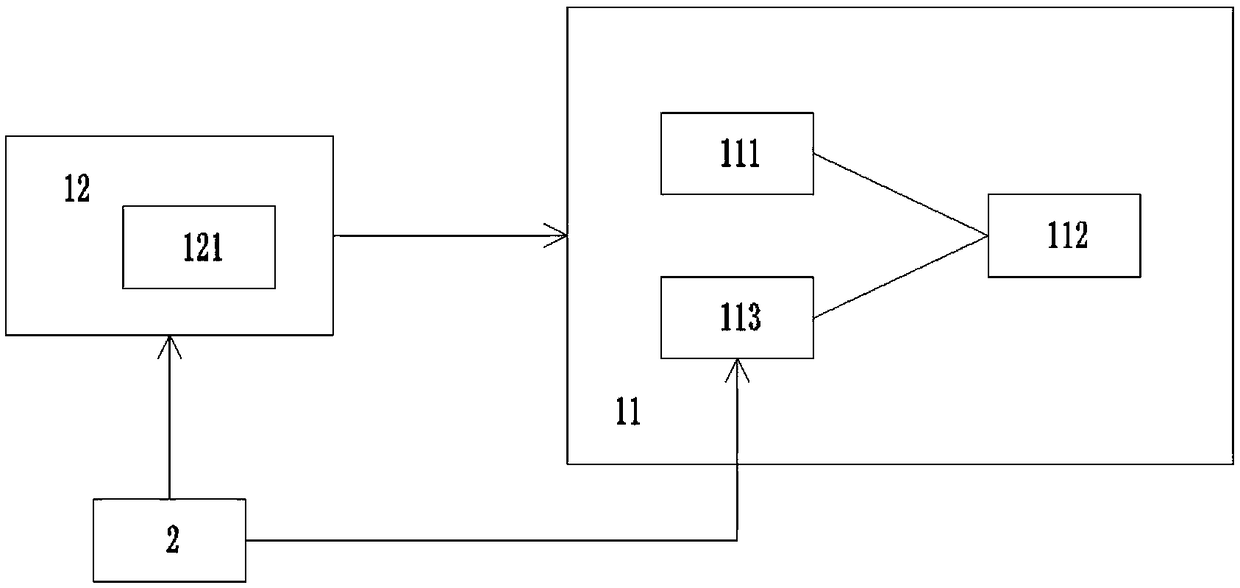

Wake-up device, indoor unit with air conditioner, air conditioner, and wake-up method of the wake-up device

InactiveCN109157727AImprove comfortImprove experience valueSleep inducing/ending devicesComputer moduleAir conditioning

The invention provides a wake-up device which include a projection module (11) for receiving a projection on signal and project a target image (4) to a target position (3) where a human body is sleeping in response to that projection on signal, and a timing module (12) for receiving the projection time signal and transmitting the projection on signal to the projection module (11) at a time point determined by the projection time signal. The invention also provides an air conditioning indoor unit with the wake-up device, an air conditioning with the air conditioning indoor unit, and a wake-up method of the wake-up device. The wake-up device of the present invention can comfortably wake a sleeping user in a projection manner.

Owner:GREE ELECTRIC APPLIANCES INC

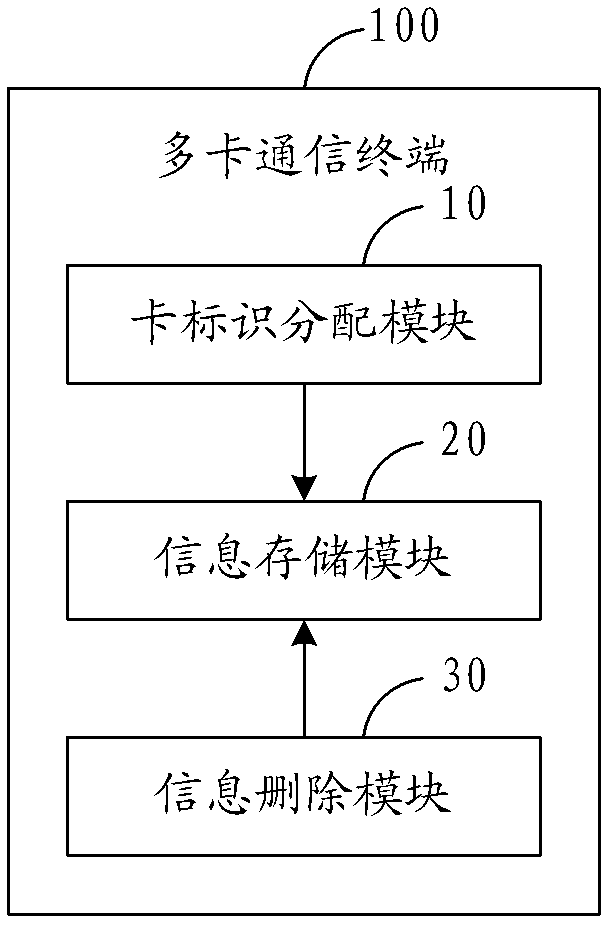

Information deletion method of multi-card communication terminal and multi-card communication terminal

ActiveCN103167480BImprove experience valueEasy to deleteNetwork data managementComputer hardwareComputer network

The invention relates to the communication technology field and provides an information deleting method of a multi-card communication terminal. The information deleting method includes the steps of distributing corresponding card identification to a user identification card, adding the card identification corresponding to the user identification card to an application record when the application record relevant to the user identification card is stored, and deleting the application record including the designated card identification after an information deleting command of the designated card identification is received. Accordingly, the invention further provides the multi-card communication terminal. The information deleting method of the multi-card communication terminal and the multi-card communication terminal has the advantages of conveniently and quickly deleting the history application record of the user identification card designated by a user.

Owner:YULONG COMPUTER TELECOMM SCI (SHENZHEN) CO LTD

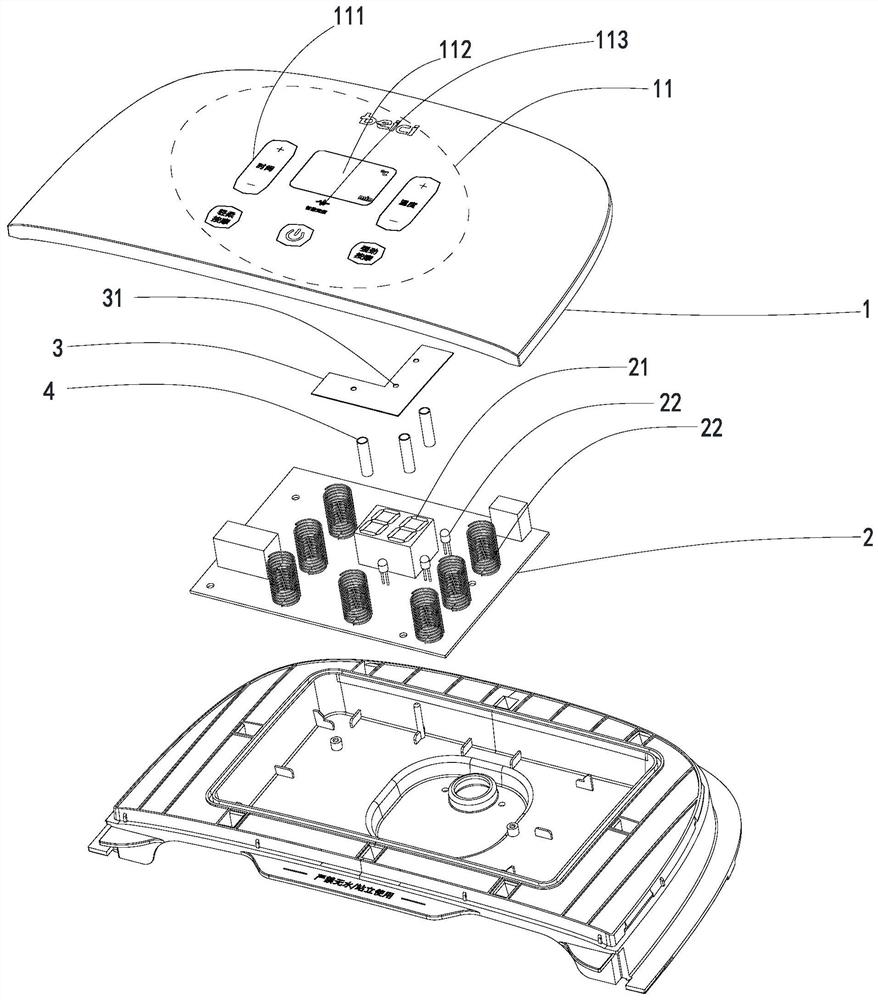

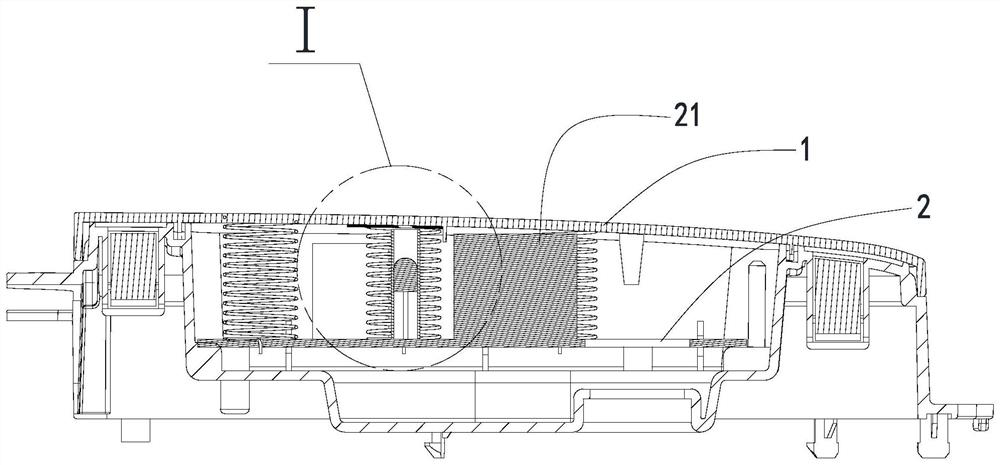

Operation display device and foot bath device

The invention provides an operation display device comprising an operation panel and a circuit board matched with the operation panel, the operation panel is provided with a function menu formed by alaser etching process, and the function menu is provided with a key area formed by a capacitive touch screen and a display area. The invention further provides a foot bath device. The foot bath devicecomprises the operation display device. The operation panel is formed through the laser etching process, the forming efficiency is high, the cost is low, lines with balanced depth are arranged on thesurface, the texture is high, falling is avoided, and the experience value is high; light emitted by a nixie tube and an LED lamp of the circuit board penetrates through the panel and is directly experienced on the panel, other transparent view windows are not needed, and the cost is low; through mutual coordination and cooperation of a shading film, a casing pipe, the LED lamp and a spring, light is well guided and controlled to pass through perspective holes, and the light is projected to the corresponding key area on a function menu made of a high-transmittance PP plastic material.

Owner:WUHU BEICI ELECTRICAL APPLIANCE CO LTD

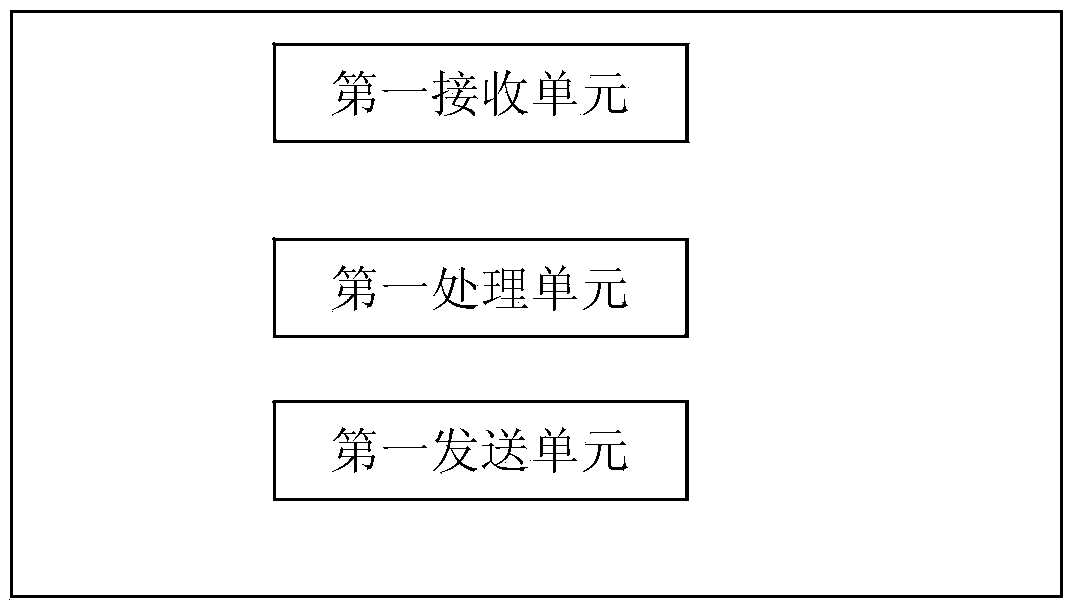

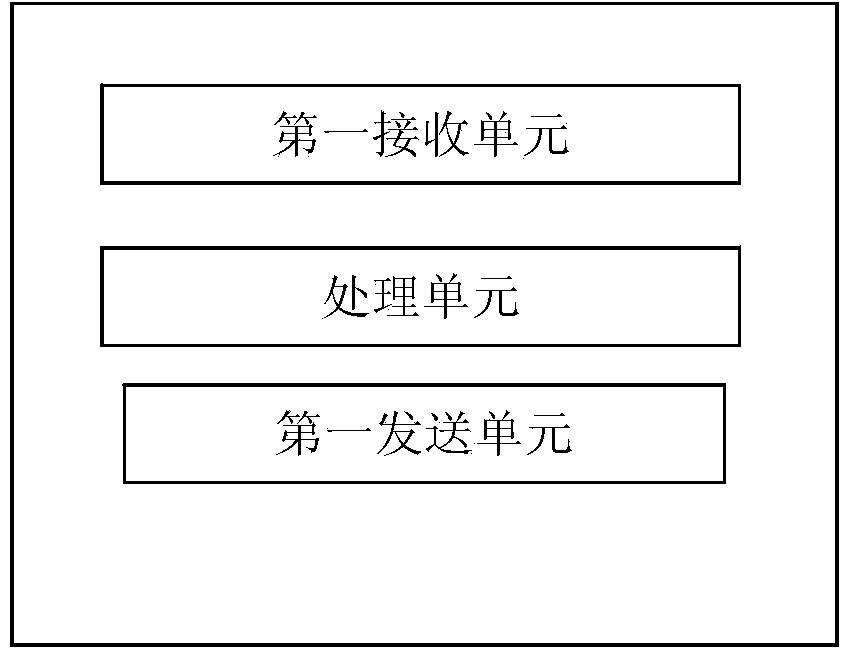

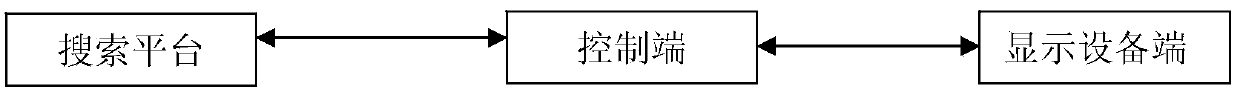

Control terminal and system for displaying optimal search result rapidly

InactiveCN103796070AQuick displayReduce the rate of manual interventionSelective content distributionDisplay deviceMobile device

The invention belongs to the field of intelligent terminals, and particularly relates to a control terminal and system for displaying an optimal search result rapidly. The control terminal and system aim to solve the problem that in the prior art, a user cannot use control terminals such as intelligent mobile devices for displaying an optimal search result. The control terminal for displaying the optimal search result rapidly comprises a first receiving unit, a processing unit and a first sending unit; the first receiving unit is used for receiving a search instruction sent out by a user; the processing unit is used for sending the search instruction to a search platform, receiving search results fed back by the search platform, and performing local processing on the search results to obtain the optimal search result; the first sending unit is used for sending the optimal search result to a display device terminal. The invention further provides the system for displaying the optimal search result rapidly. The system comprises the display device terminal and the control terminal, the control terminal and the display device terminal perform information interaction through a communication network, and the control terminal and the search platform perform information interaction through the communication network. The control terminal and system for displaying the optimal search result rapidly are applicable to the intelligent terminals.

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

Data display system and display method

InactiveCN101339554BImprove experience valueIntuitive displaySpecial data processing applicationsGraphicsData display

Owner:刘宜云

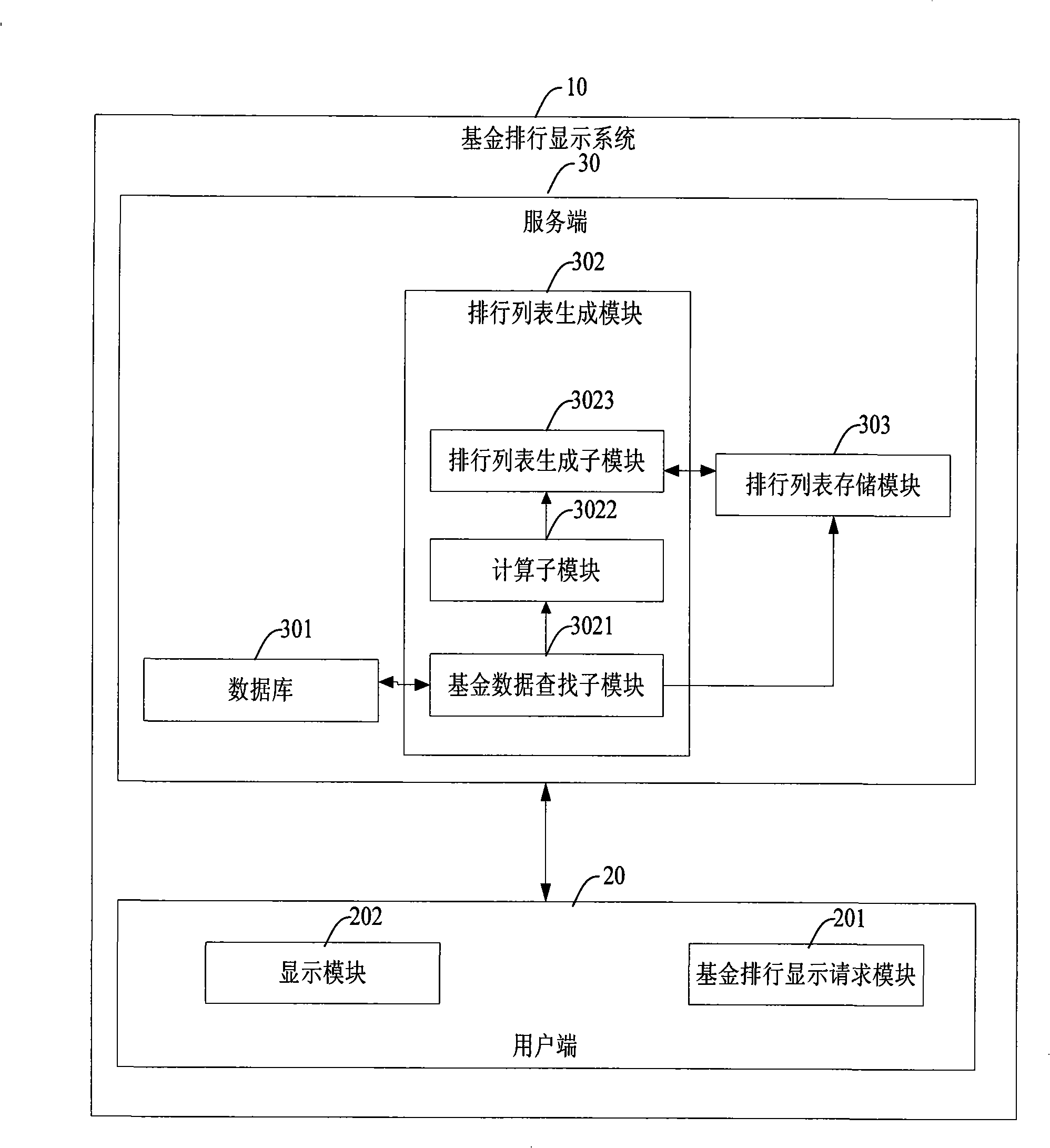

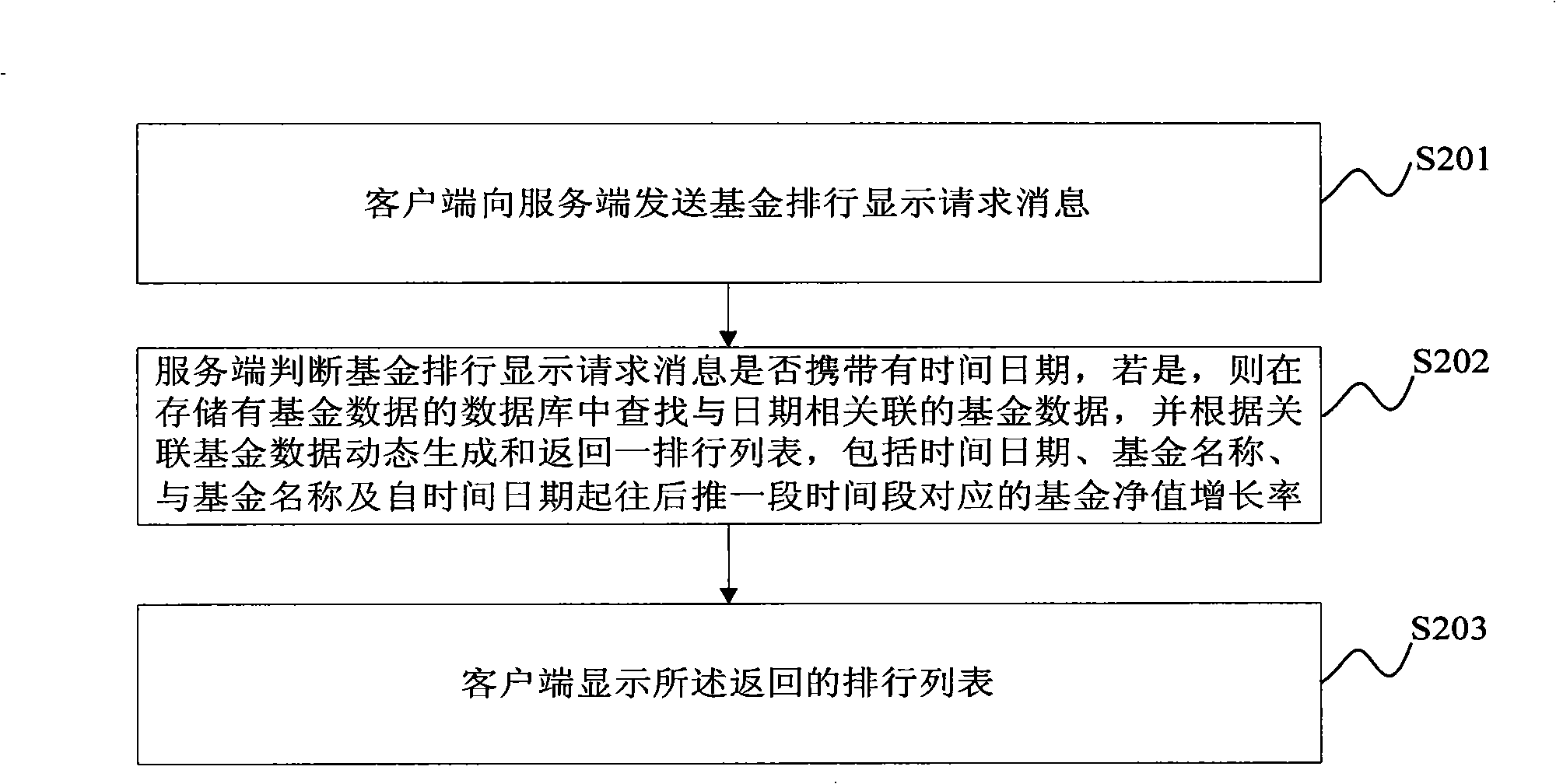

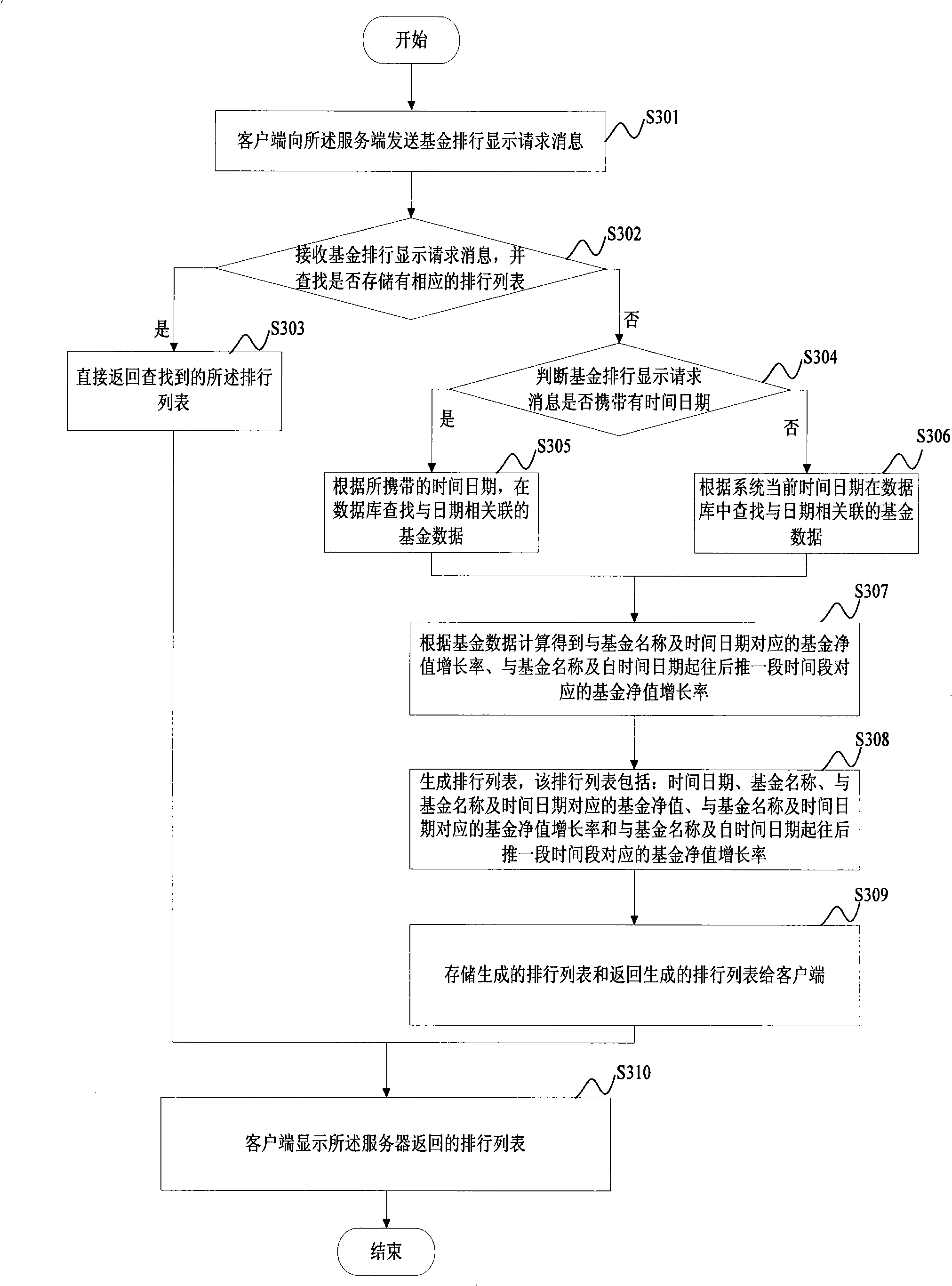

Fund ranking display system and fund ranking display process

InactiveCN101334881AIn line with the habitImprove experience valueFinanceSpecial data processing applicationsHabitInformation searching

The invention discloses a fund ranking display system and a method thereof, which comprises a client-side and a service side. The service side consists of: a database used for storing fund information, and a ranking list generation module. The ranking list generation module is used for judging whether the request carries time and date information when receiving a fund ranking display request sent by the client-side, if the request carries time and date information, relevant fund information corresponding to the time and date is searched in the database, and a ranking list is dynamically generated and returned according to the relevant fund information searched. The ranking list comprises: time and date, fund name, fund net value and fund net value growth rate. The client-side comprises: a fund ranking display request module to send the fund ranking display request information to the client-side and a display module to display the returned ranking list. By this method, the system accords with user habit, thus improving the experience value of the user.

Owner:刘宜云

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com