Plate collecting device

A technology of plate closing device and plate, which is applied in conveyor control device, transportation and packaging, conveyor, etc., can solve problems such as plate damage, and achieve the effect of high plate closing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

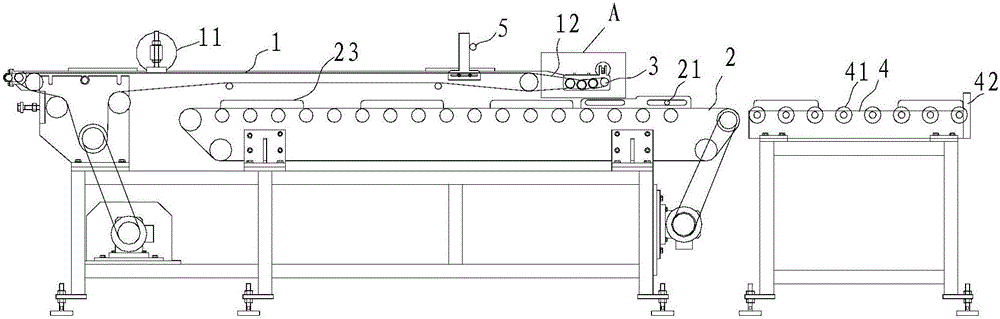

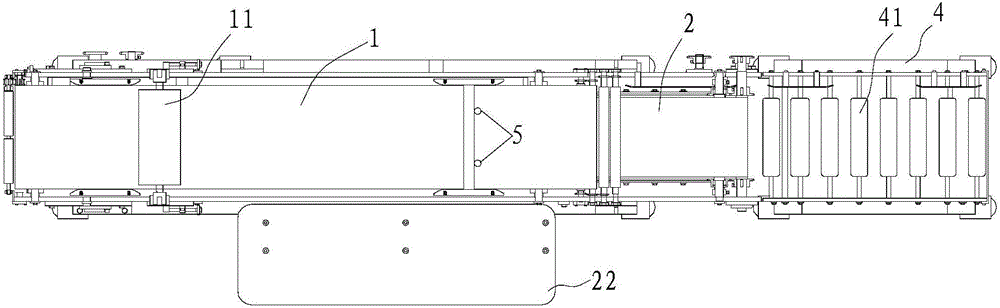

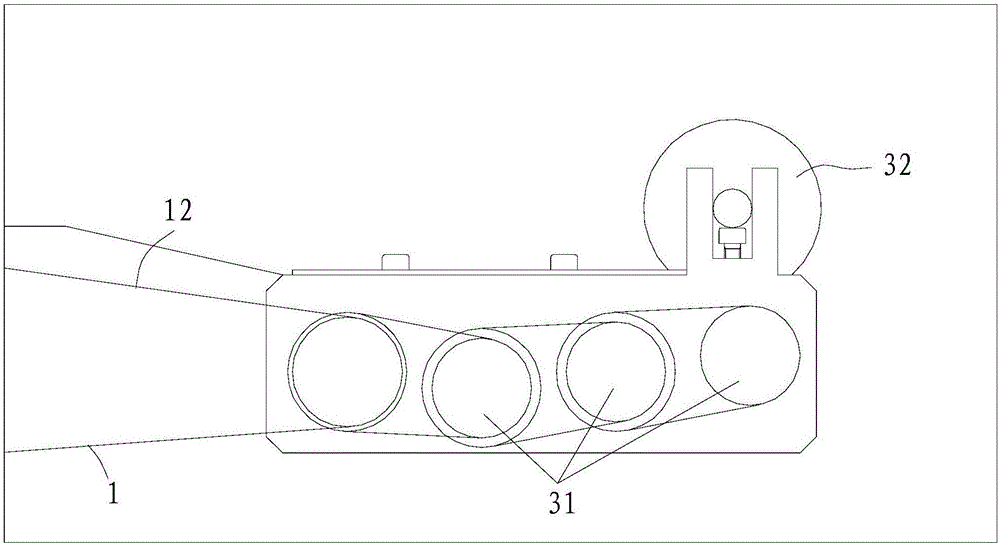

[0024] Such as Figure 1~3 As shown, a plate receiving device includes: a conveyor belt 1, a conveyor belt 2, a sheet throwing mechanism 3, a transfer frame 4 and a counting sensor 5. The conveyor belt 1 is used for continuously conveying the polar plates. The conveyor belt 1 is provided with a sheeting roller 11. After being pressed by the sheeting roller 11, the polar plates become flat, which is conducive to the stacking and storage of subsequent polar plates and the preparation of subsequent polar plates. The outfeed end of the conveyor belt 1 has a downwardly inclined section 12 .

[0025] The conveyor belt 2 is arranged below the discharge end of the conveyor belt 1, and is used for intermittently conveying the storage tray, and the storage tray is used to hold the pole plates dropped by the conveyor belt 1. The conveyor belt 2 is a chain conveyor belt, and positioning bars are arranged at regular intervals, and the distance between the two positioning bars just places ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com