Automatic casting machine

An automatic pouring and ladle technology, which is applied in the control of pouring molten metal from the ladle, metal processing equipment, casting equipment, etc., can solve the problems of increased production cost, potential safety hazards, personal injury, etc., and achieves low structural cost. , and the effect of removing potential safety hazards and isolating heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

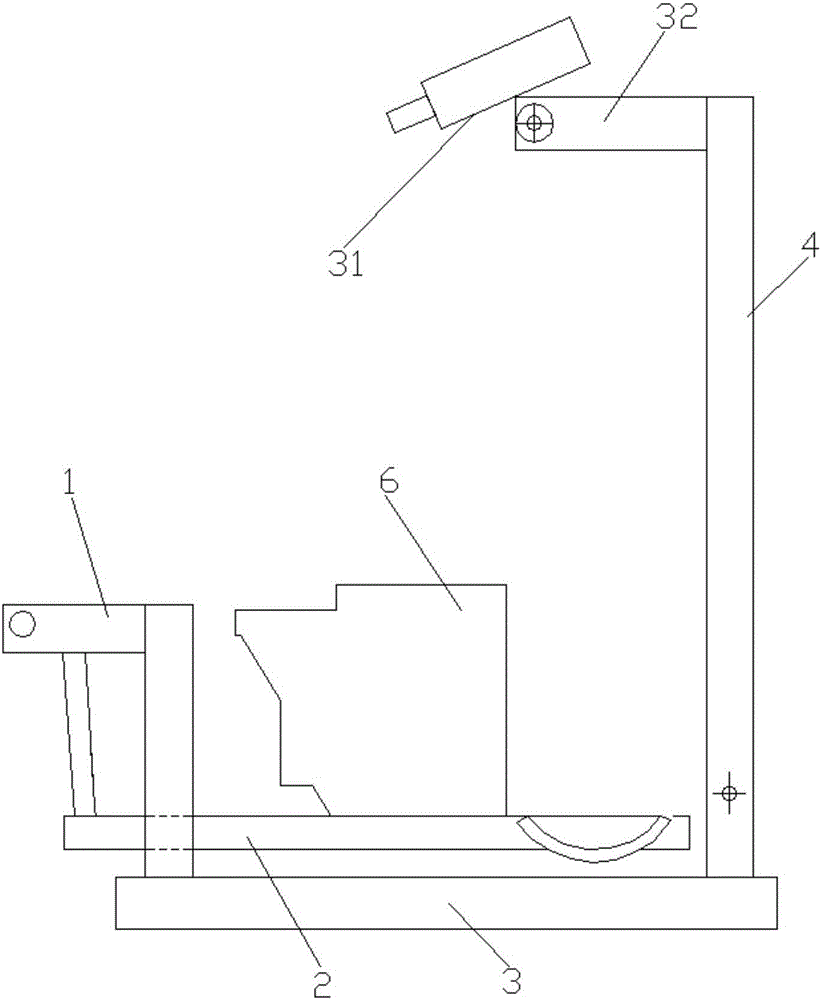

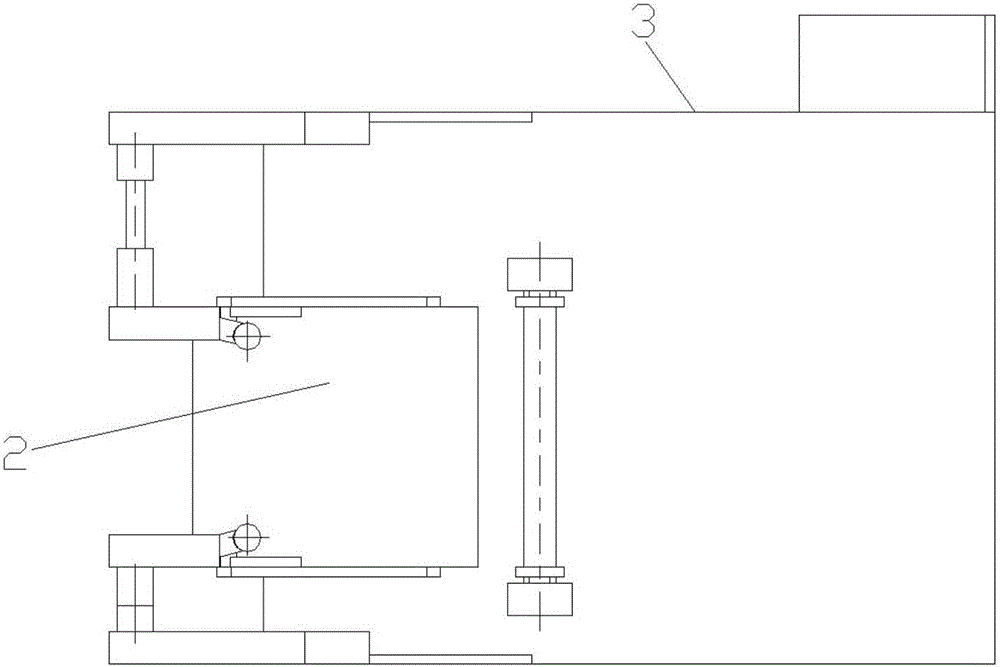

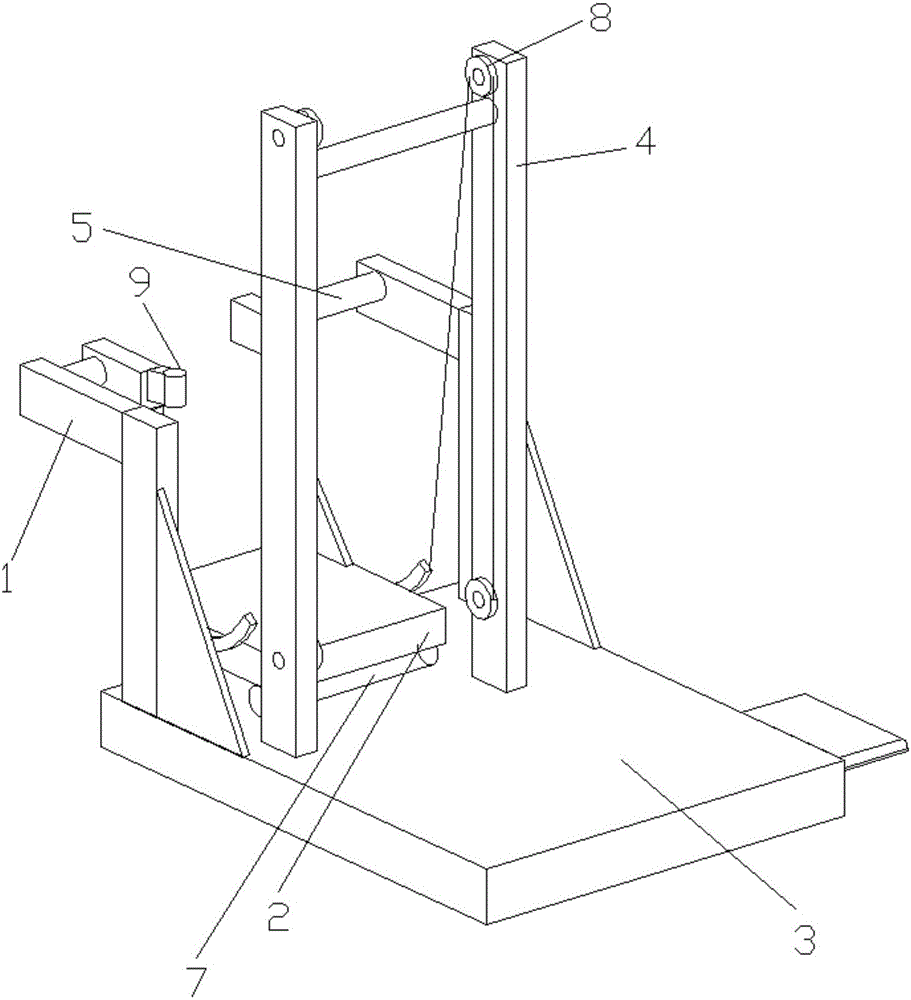

[0043] Such as Figure 1-17As shown, it shows a specific embodiment of the present invention. As shown in the figure, the present invention discloses an automatic pouring machine, which includes an upper platform 3, and a bracket for rotating and installing a rotating bracket 2 is arranged in parallel on the upper platform. 1 and a frame 4 for installing the pulley; the frame is arranged at the rear of the support; the frame includes two columns arranged parallel to each other, and the pulley includes an upper pulley 8 and a lower pulley, and the upper pulley and the lower pulley are rotatably installed on On the surface of the opposite side of the two uprights; the end of the rotating bracket near the frame side is fixedly connected with a rope 27, and the far end of the rope is pulled by a motor after passing through the upper pulley and the lower pulley; the rotating bracket The end on the side away from the frame is rotatably mounted on the bracket;

[0044] As shown in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com