Adjusting device of shock absorber springs for automobile

A technology of adjusting device and shock absorber is applied in the field of automobile maintenance tools, which can solve the problem of high automobile maintenance cost and achieve the effect of solving the cost increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

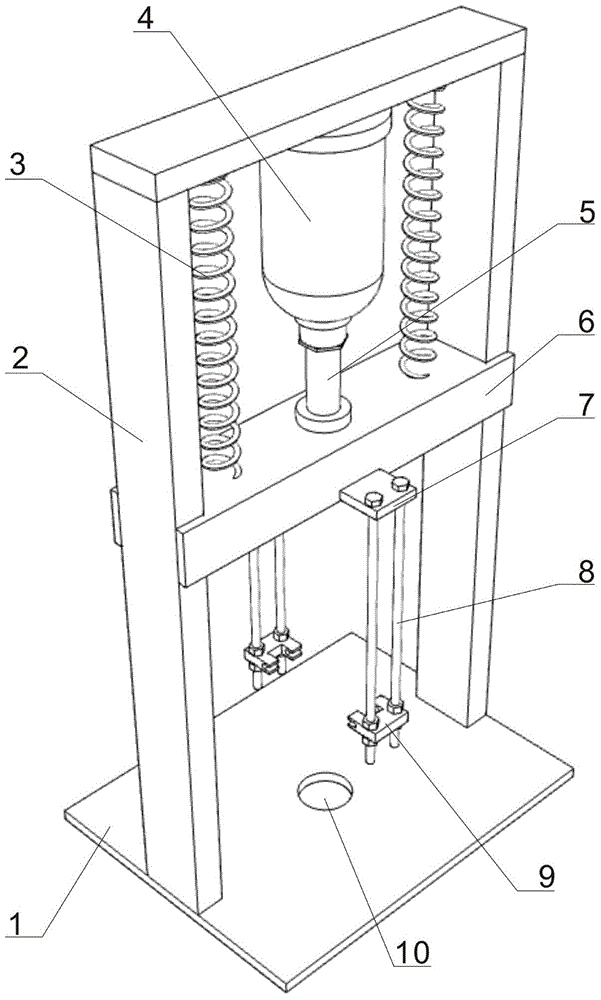

[0020] Example: When using, first place the shock absorber spring that needs to be shaped in the installation hole 10 in the middle of the base 1, adjust the height of the slide plate 6 through the jack 4, and then realize the height of the jacket 9 and the column 8, after reaching the predetermined height. , clamp the edge of the shock absorber spring with the jacket 9, the jack 4 works again, drives the slide plate 6, the column 8, the support plate 7 and the jacket 9 to lift synchronously, and the shock absorber spring is gradually stretched. When the predetermined stretch is reached After the length, the jack 4 is braked and kept in this state for 12 hours to ensure the shape of the shock absorber spring. After 12 hours, the shock absorber spring has completed the shaping process, the jacket 9 is removed, the shock absorber spring is taken out, and then the pressure of the jack 4 is relieved, and the slide plate 6 returns to the state before use under the action of the spri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com