Methods of Recycling Targets

A technology with the same target and material, applied in metal material coating process, vacuum evaporation plating, coating, etc., can solve the problems of affecting the purity of metal, easy to mix impurities, high recovery cost, etc., and achieve the improvement of purity and sputtering performance , improve recycling rate, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

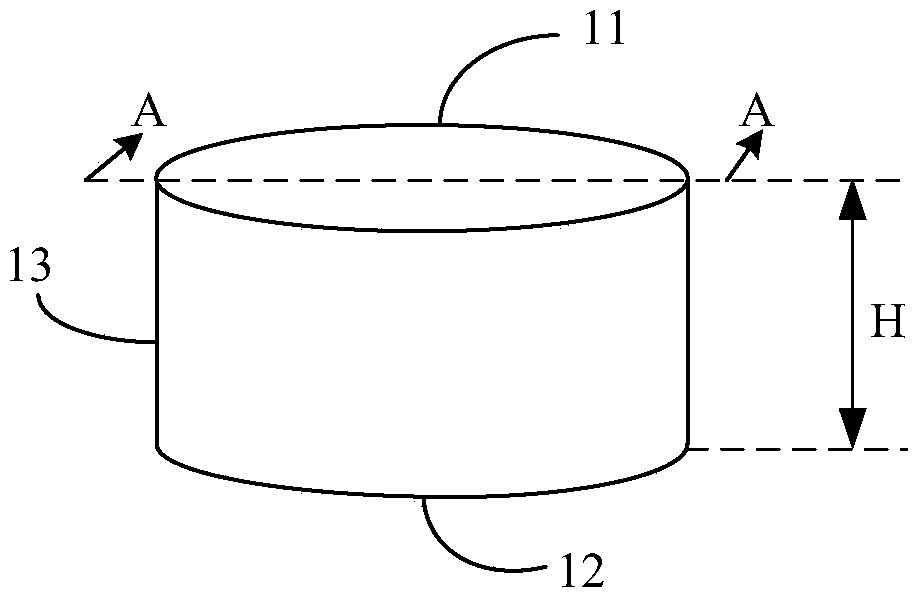

[0032] Firstly, step S11 is performed to provide at least two targets of the same material to be recycled.

[0033] In this embodiment, the target material to be recovered is the target material after vacuum sputtering. The shape of the target is not limited. The formation method of the target material to be recovered is as follows:

[0034] After vacuum sputtering, the target assembly is removed.

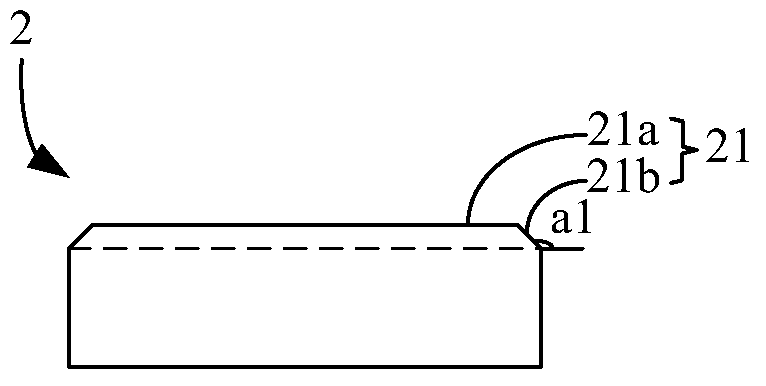

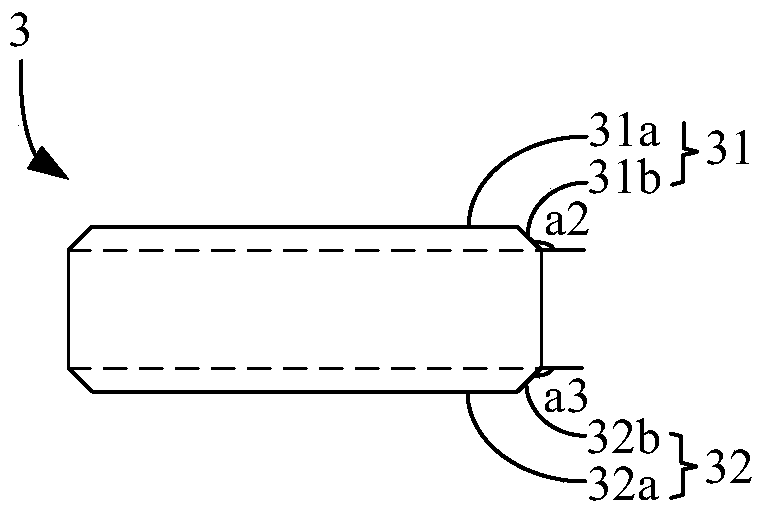

[0035] Afterwards, a grinding machine is provided, the grinding machine has an object table and a grinding head, the table surface of the object table is opposite and parallel to the grinding surface of the grinding head, and the target assembly is placed on the object table , the target is in contact with the stage, and the grinding head is in contact with the back plate.

[0036] Afterwards, the stage is set to rotate clockwise or counterclockwise, and the rotational speed of the stage is greater than or equal to 50 r / min and less than or equal to 200 r / min. The rotation dire...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com