Small railway maintenance machine provided with sleeper end ballast clearing device

A stone-clearing, small-scale technology, applied in track maintenance, roads, track superstructure, etc., can solve problems such as time-consuming, labor-intensive, sleeper damage, and low work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

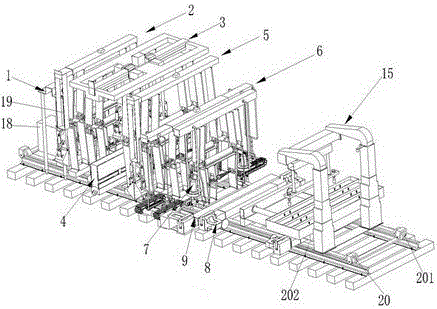

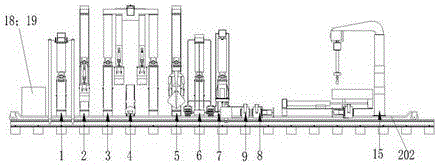

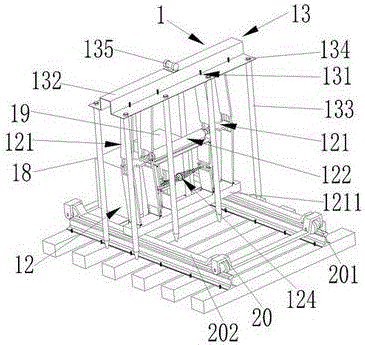

[0186] see figure 1 and figure 2 Shown, the present invention is made up of tamping ballast leveling device 1, road shoulder and ballast bed shaping device 2, grab stone clearing device 3, ballast collecting and discharging device 4, pillow end stone cleaning device 5, sprocket stone removing device 6 , Four nuts synchronous assembly and disassembly device 7, the first rail lifting device 8, rail transfer and push-pull sleeper device 9, sleeper lifting device 15, generator 18, hydraulic system and control system box 19 and rail car 20 composition. The rail car is equipped with multiple casters 201 and two longitudinal beams 202, tamping ballast leveling device 1, road shoulder and ballast bed shaping device 2, grab stone cleaning device 3, ballast collecting and discharging device 4, pillow end stone cleaning device 5. Sprocket stone removal device 6, four-nut synchronous assembly and disassembly device 7, first rail lifting device 8, rail transition and push-pull sleeper de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com