Oil tank truck remote monitoring system

A technology of remote monitoring system and remote control system, applied in general control system, control/adjustment system, program control, etc., can solve problems such as wrong loading and unloading of oil products, insufficient control, and failure to load and unload oil products, etc., to prevent The effect of misfitting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

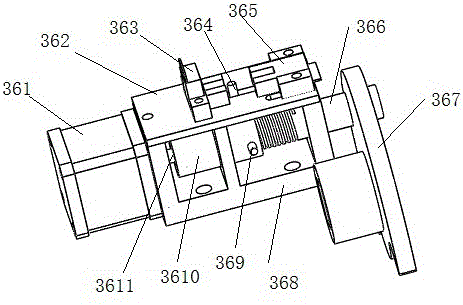

[0047] In order to further illustrate the technical solution of the present invention, the implementation mode of the present invention is now specifically described in conjunction with the accompanying drawings, as Figure 14 , Select steel material to make lock disc 367 in this example, select the diameter 30 millimeters of disc hub 3671, height 20 millimeters; Select the diameter 100 millimeters of disc body 3672, thickness 8 millimeters; Select the height 4 millimeters of steps 3673 diameter 55 millimeters; Select The installation hole is a rectangular hole with a side length of 18 millimeters; the diameter of the locking pin hole 3675 is 13 millimeters and is located on the circumference of the disk body 3672 side diameter of 80 millimeters; the angle between the two positioning sides 3676 of rotation is 90 °, so that The implementation of the lock plate 367 is completed.

[0048] Such as Figure 13 , select metal aluminum as the material of guide bar 364 in this example...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com