Material level detection device for powder silo and material level detection method

A material level detection and silo technology, applied in measuring devices, lubrication indicating devices, engine lubrication, etc., can solve problems such as hidden dangers in the inventory method and large data errors, so as to save labor, improve production and avoid potential safety hazards Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

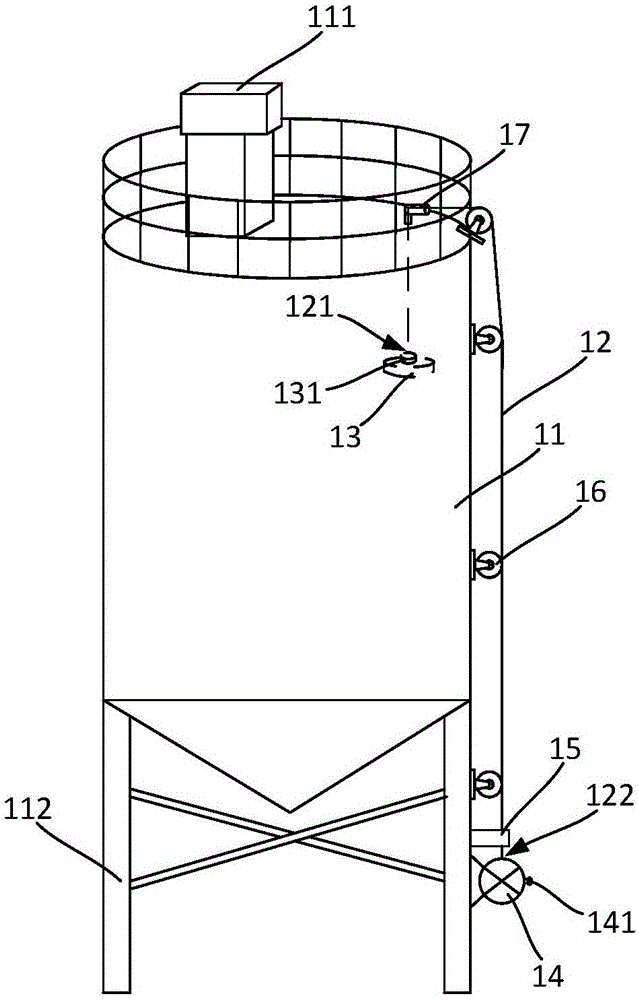

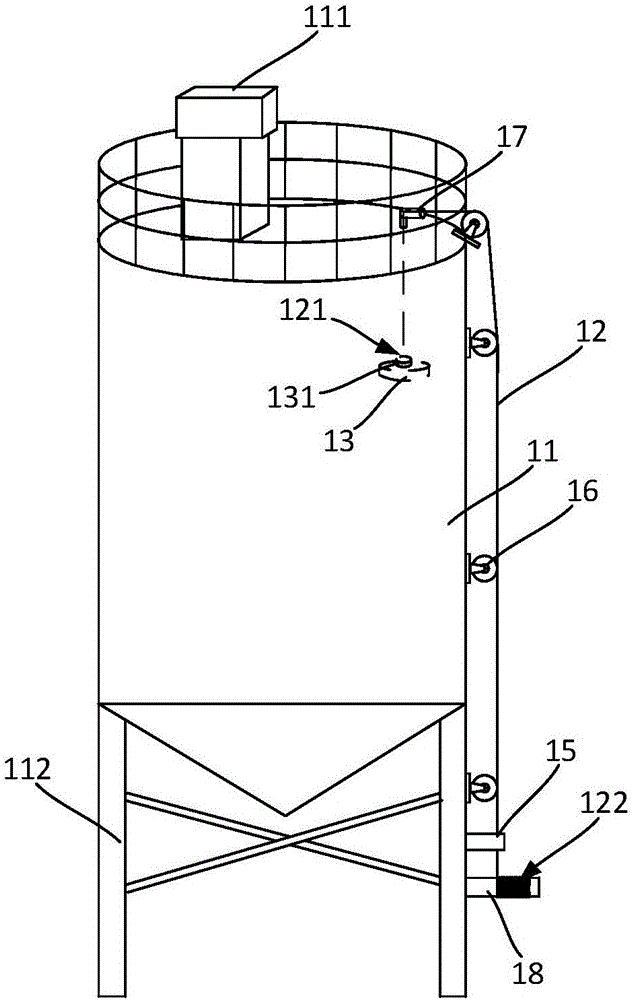

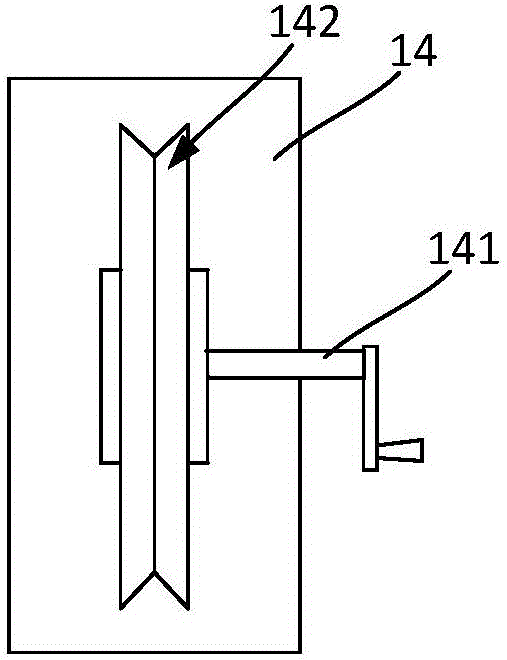

[0056] As another preferred embodiment of the present invention, the material level detection method also includes:

[0057] A plurality of positioning pulleys 16 are fixed on the outside of the silo body 11 , and the outer surface of the positioning pulleys 16 is provided with a limit groove 161 matching the detection rope 12 , and the detection rope 12 is limited by the positioning pulleys 16 . The limit groove 161 plays the role of supporting and limiting the detection rope 12, which can keep the detection rope 12 straight during the process of falling and rolling up, and avoid the phenomenon that the detection rope 12 is stuck and affects the detection.

[0058] As another preferred embodiment of the present invention, the material level detection method also includes:

[0059] Install an L-shaped rope inlet pipeline 17 at the detection port;

[0060] A guide pulley for the limit detection rope 12 is installed in the horizontal pipe and the vertical pipe of the rope inlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com