Pillow changing machine with chain-tooth stone discharging device

A chain tooth and lifting device technology, applied in the field of railway maintenance machinery, can solve problems such as sleeper sinking, time-consuming and labor-intensive, and sleeper damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

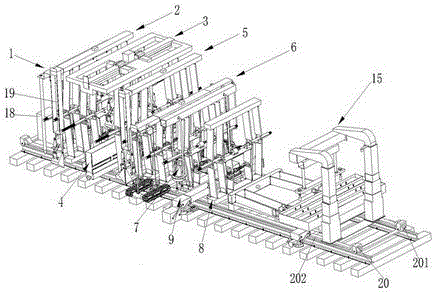

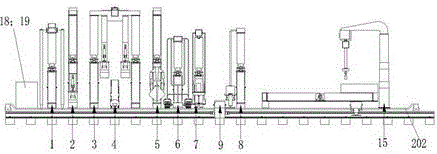

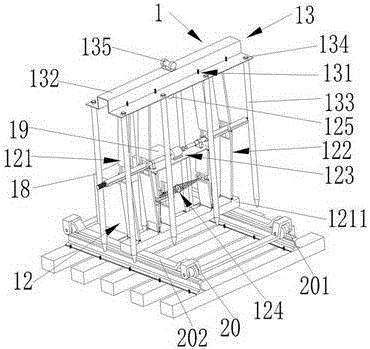

[0191] see figure 1 and figure 2 As shown, the present invention is composed of a tamping ballast device 1, a shoulder and track bed repairing device 2, a grab stone cleaning device 3, a ballast collecting device 4, a pillow end stone cleaning device 5, and a chain tooth stone removing device 6 , Four nut synchronous assembly and disassembly device 7, first rail device 8, rail transfer and push-pull sleeper device 9, sleeper lifting device 15, generator 18, hydraulic system and control system box 19 and rail car 20. The rail car is provided with a plurality of casters 201 and two longitudinal beams 202, a tamping ballast device 1, a shoulder and track bed modification device 2, a grab stone cleaning device 3, a ballast collection device 4, and a pillow end stone cleaning device 5. The sprocket stone removal device 6, the four-nut synchronous assembly and disassembly device 7, the first rail lifting device 8, the rail transfer and the push-pull sleeper device 9, the sleeper l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com