Inner line running bicycle frame and line running method for bicycle frame

A technology for bicycles and internal wiring, which is applied to bicycle racks, bicycle accessories, bicycle auxiliary equipment, etc., can solve the problems of affecting the appearance, easy to damage control lines, and leakage of wiring, so as to save energy, reduce wind resistance, and facilitate cleaning body effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

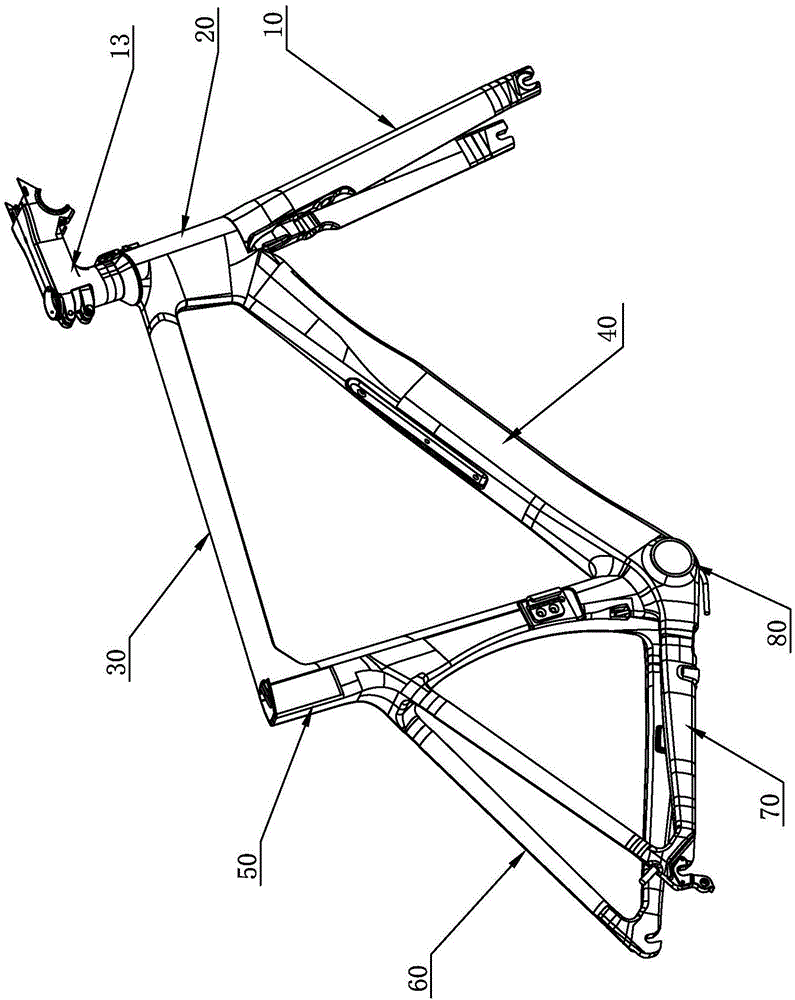

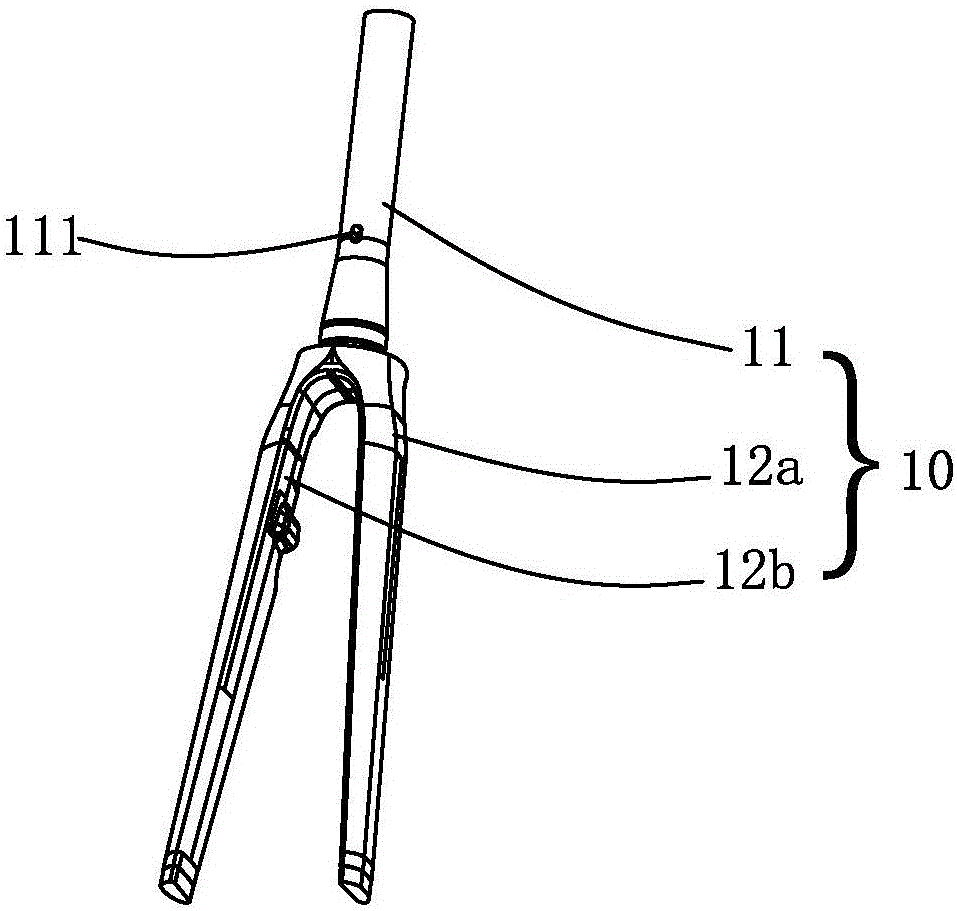

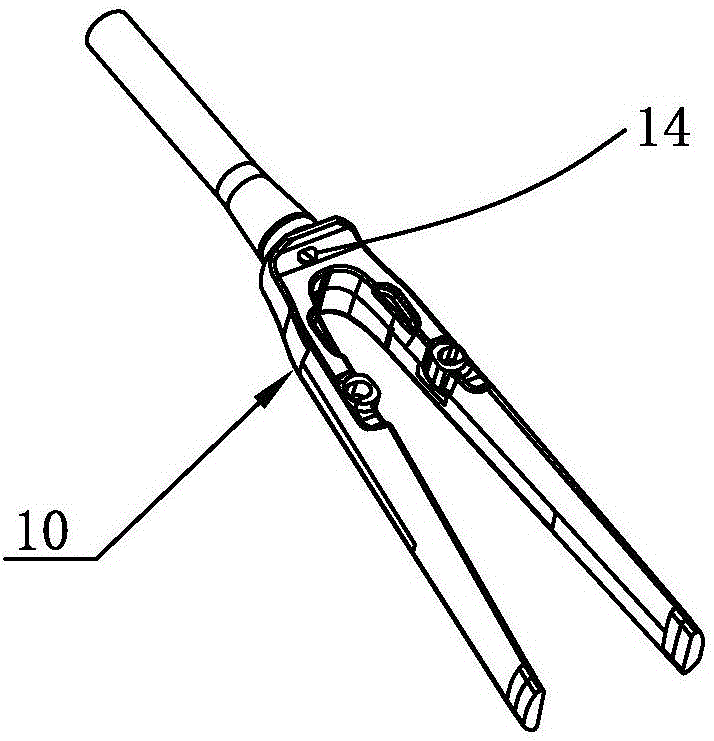

[0042]In this embodiment, the front fork 10 includes a standpipe 11 and a left front fork 12 a and a right front fork 12 b fixed to the bottom of the standpipe 11 . The standpipe 11 is rotatably installed in the head pipe 20. The top of the standpipe 11 is covered with a fixed sleeve 13 for installing the handlebar. Between the seat pipe 11 and the head pipe 20 , there is a gap for wiring between the seat pipe 11 and the head pipe 20 . The fixed sleeve 13 is provided with at least one wire hole 131, the wire hole 131 runs through the free end and the bottom end of the fixed sleeve 13, the riser 11 is provided with a wire hole 111, and the front fork 10 is opened near the position where the front brake is installed. There are outlet holes 14. The cable routing hole 131 , the gap, the cable inlet hole 111 , the inner chamber of the standpipe 11 , and the cable outlet hole 14 are sequentially connected to form a channel for wiring the front fork. In this way, the front fork con...

Embodiment 2

[0050] like Figure 10 As shown, the front fork 10 includes a standpipe 11 and a left front fork 12 a and a right front fork 12 b fixed to the bottom of the standpipe 11 . The standpipe 11 is rotatably installed in the head pipe 20. The top of the standpipe 11 is covered with a fixed sleeve 13 for installing the handlebar. Between the seat pipe 11 and the head pipe 20 , there is a gap for wiring between the seat pipe 11 and the head pipe 20 . At least one wiring hole 131 is arranged in the fixing sleeve 13, and the wiring hole 131 runs through the free end and the bottom end of the fixing sleeve 13. The inner wall of the head pipe 20 is provided with a head pipe inlet hole (not shown in the figure). The line hole communicates with the lower pipe 40 .

[0051] In order to facilitate the threading of the lower fork control wire, a groove 81 is provided at the bottom of the bottom bracket 80 , and a plurality of first through holes 82 are relatively provided on the inner walls ...

Embodiment 3

[0058] The present invention also provides a bicycle frame with inner cables, including: the cable routing channel for the front fork provided in the first embodiment and the cable routing channel for the lower fork provided in the second embodiment.

[0059] This embodiment also provides a cable routing method for the bicycle frame with inner cables, including: the cable routing method for the front fork provided in the first embodiment and the cable routing method for the lower fork provided in the second embodiment. When the above-mentioned front fork wiring and lower fork wiring are used at the same time, the overall control line of the frame can be hidden, and the overall aesthetics of the frame can be greatly improved. In addition, the overall hidden wiring can further reduce wind resistance, so that the rider can save energy and ride faster.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com