Sand washing method and special tool

A special tool and sand flushing technology, applied in the field of workover operations, can solve the problems of low sand flushing efficiency and inability to achieve rotary drilling, and achieve the goal of improving sand flushing efficiency, reducing the risk of sand flushing and sticking, and reducing construction environment pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

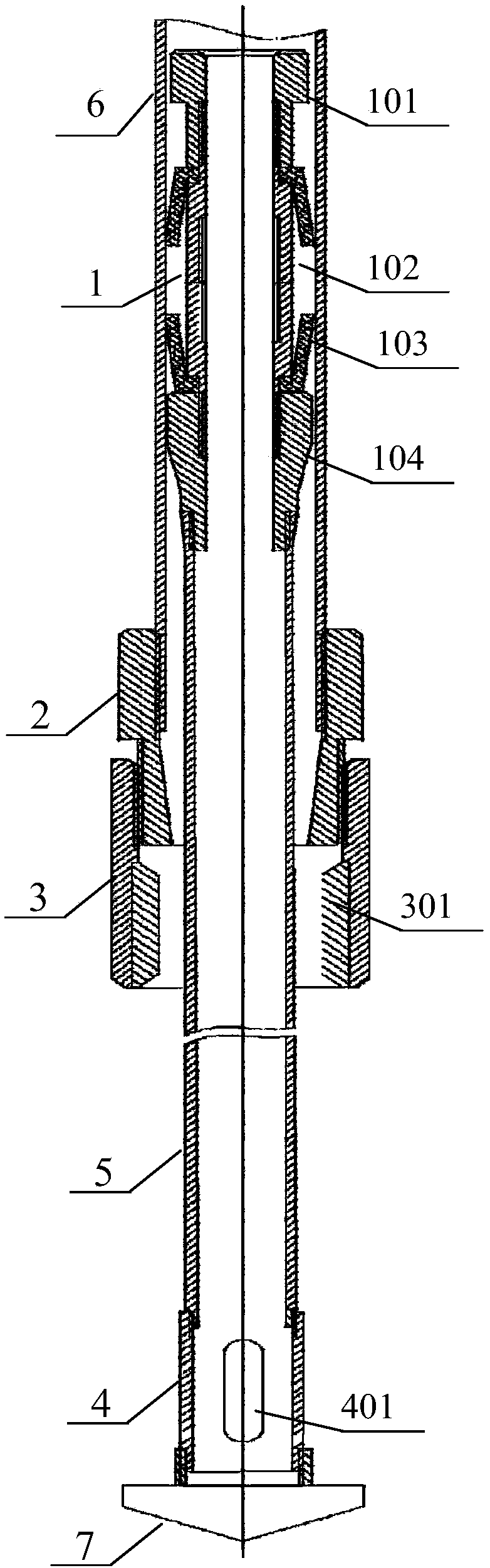

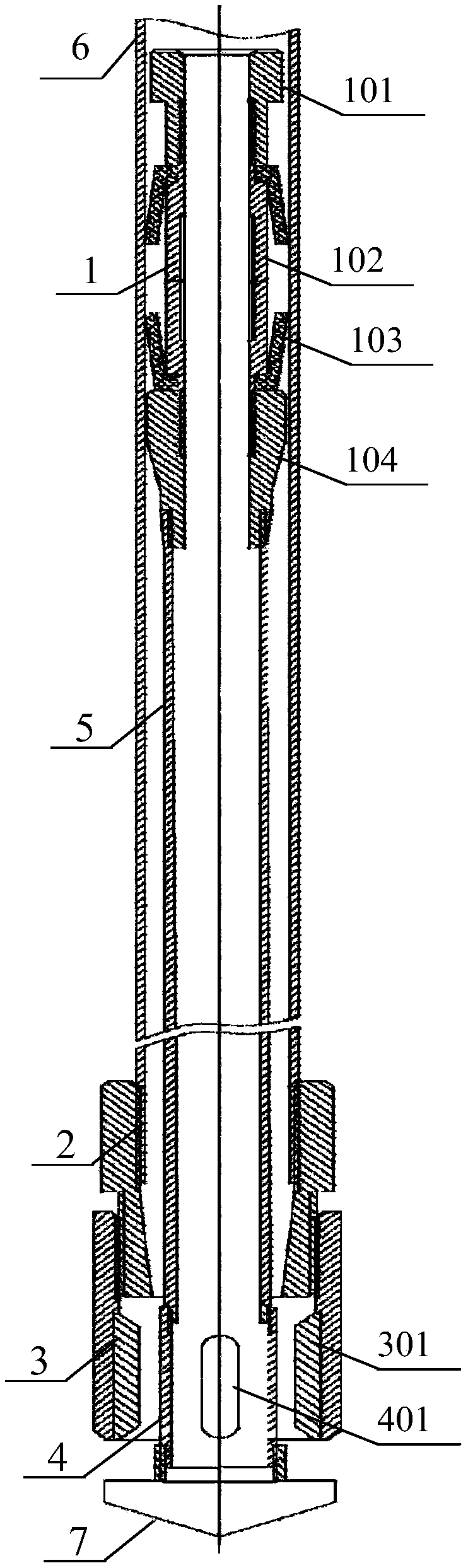

[0024] Depend on figure 1 , figure 2 As shown, a special tool for sand washing includes an outer pipe and an inner pipe for sand washing. The outer pipe is formed by screwing the oil pipe 6, the suspension nipple 2 and the rotating outer cylinder 3 sequentially. The inner pipe is made of the sealing nipple 1, the flushing pipe 5 , The rotating inner cylinder 4 and the drill bit 7 are threaded in sequence.

[0025] The central through hole of the suspension sub-section 2 is a tapered seat, and the upper and lower ends of the suspension sub-section 2 are provided with connecting threads.

[0026] The rotating outer cylinder 3 is a tubular structure, the lower port is a guide shoe, and at least two longitudinal bar-shaped transmission keys 301 are provided in the central through hole.

[0027] The sealing nipple 1 is composed of an upper joint 101, a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com