Universal rotating bracket and mounting method therefor

A technology of universal rotation and installation method, applied in the direction of machine/support, supporting machine, mechanical equipment, etc., can solve the problems of large support, difficult processing and assembly, inability to rotate freely, etc., and achieve the effect of simple installation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

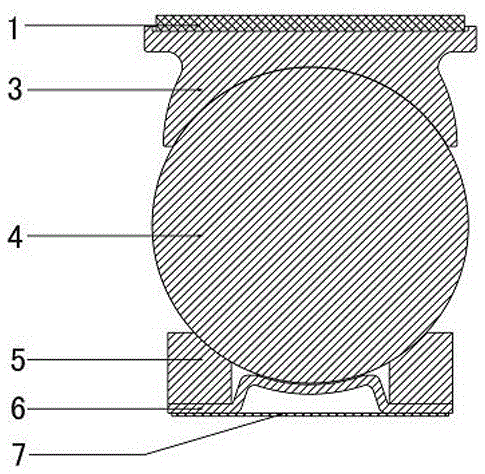

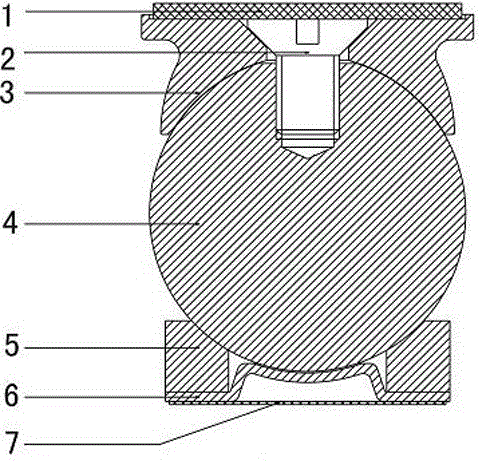

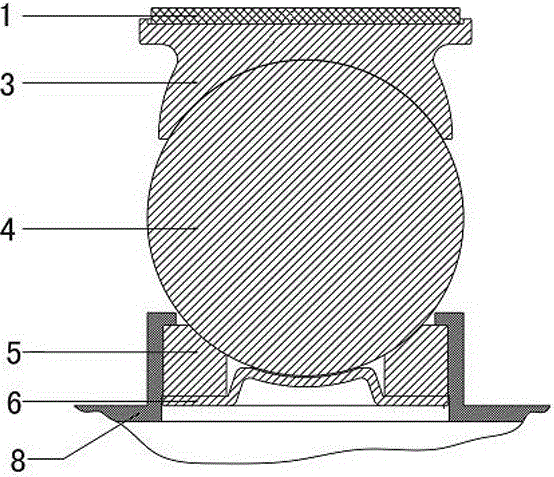

[0038] refer to figure 1 , figure 1 It is a schematic structural diagram of a universal rotating bracket according to an embodiment of the present invention. figure 1 The shown universal rotating bracket includes a first sticker 1 , a base 3 , a metal ball 4 , a magnetic ring 5 , a metal washer 6 and a second sticker 7 . The base 3 and the metal ball 4 are fixedly connected by glue, the metal ball 4 is connected to the magnetic ring 5 by magnetic force, the metal washer 6 is connected to the magnetic ring 5 by magnetic force, and the first surface of the first sticker 1 is pasted on the bottom surface of the base 3 . The second surface of the first sticker 1 is also sticky, wherein the first surface and the second surface of the first sticker 1 are the front and back of the first sticker 1 respectively. The first surface of the second sticker 7 is pasted on the metal washer, and the second surface of the second sticker 7 is pasted on the shell of the main body of the install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com