Vented high pressure valve

A valve chamber and valve body technology, which is applied in the field of high-pressure valves, can solve the problems of valve motion control, valve body and valve seat wear, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

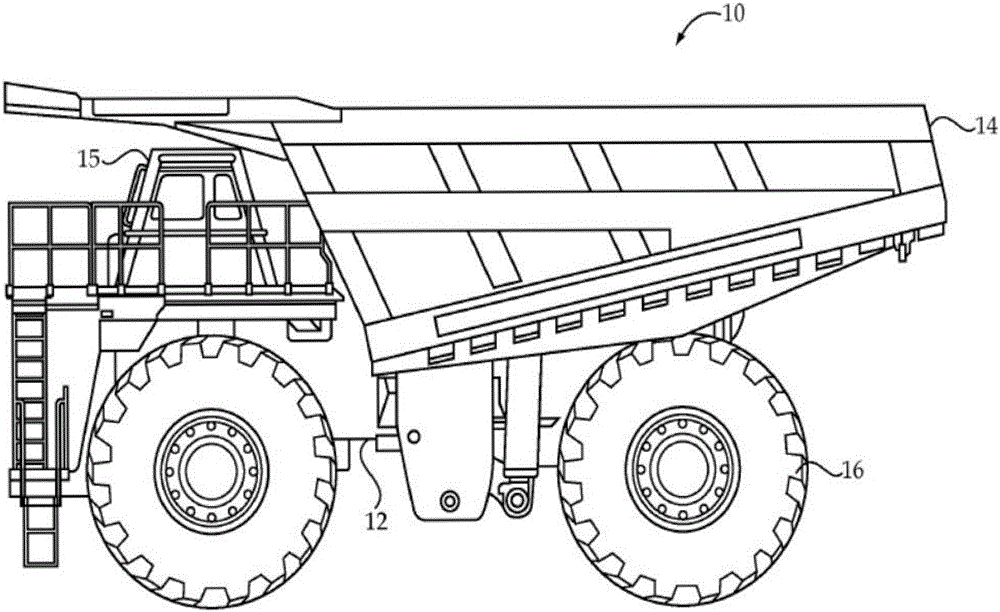

[0019] Referring now to the accompanying drawings, and specifically to figure 1 , the machine 10 includes a machine body 12 supported on a vehicle 16 . In the illustrated embodiment, machine 10 is shown as a mining truck and vehicle 16 is shown as wheels. However, the machine 10 may take a very wide variety of forms, and the form of the vehicle 16 may vary widely. For example, the vehicle 16 could be a track or possibly even a propeller if the machine is in the form of a sea-going vessel. Machine 10 includes a dump body 14 pivotally attached to machine body 12 and also includes an operator station 15 . It is contemplated that the duty cycle of the machine 10 includes periods of idling and not moving, such as when the machine 10 is waiting to accommodate a load, such as ore, into the dump body 14, to dump a load, and possibly even to be refueled. Between these quiescent idle periods, it is contemplated that the machine 10 operating at full power with a heavy load in the dump...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com