Light bar and backlight module including the light bar

A light bar and LED lamp technology, which is applied in the field of backlight modules, can solve the problems of part offset, poor welding, and high production costs, and achieve the effects of improving assembly efficiency, high installation efficiency, and low use cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

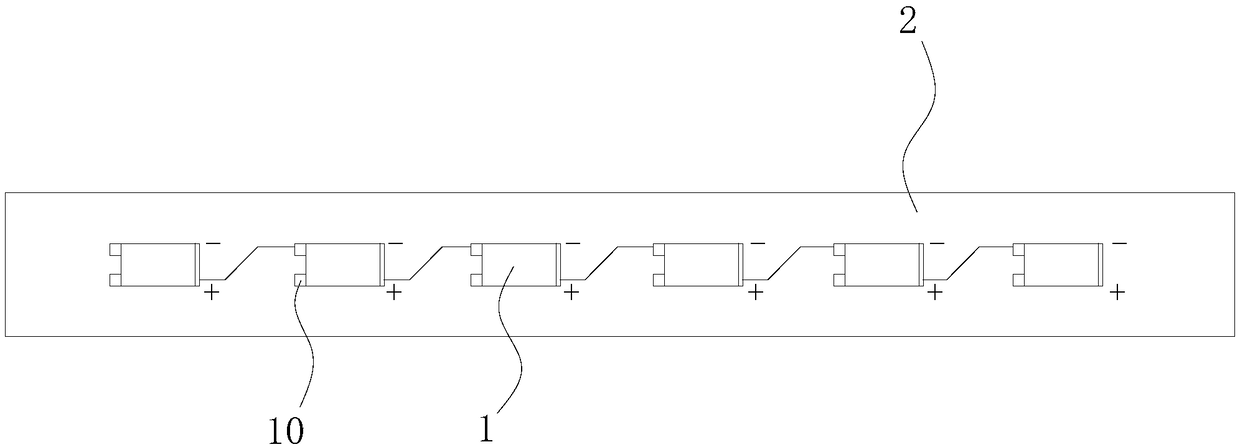

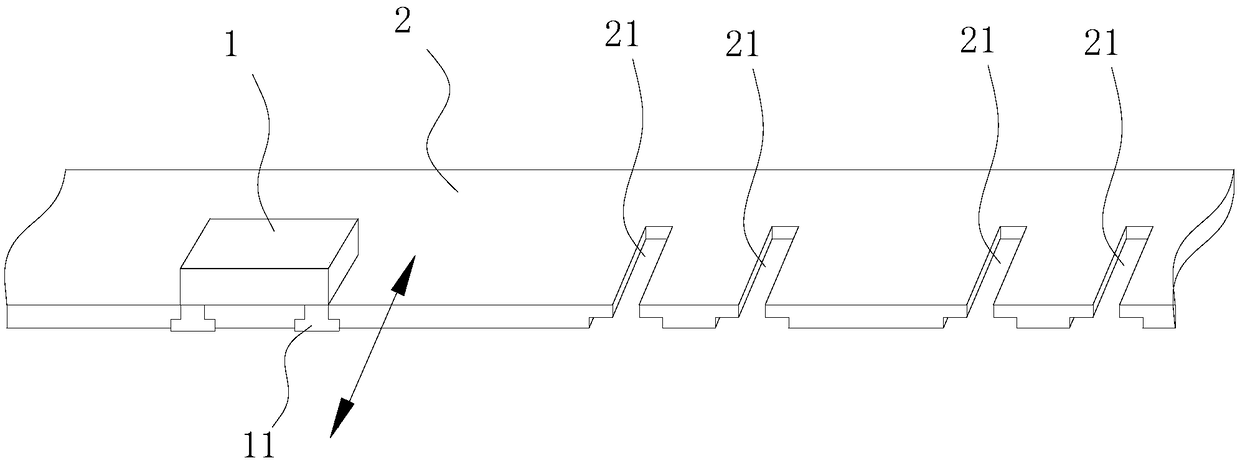

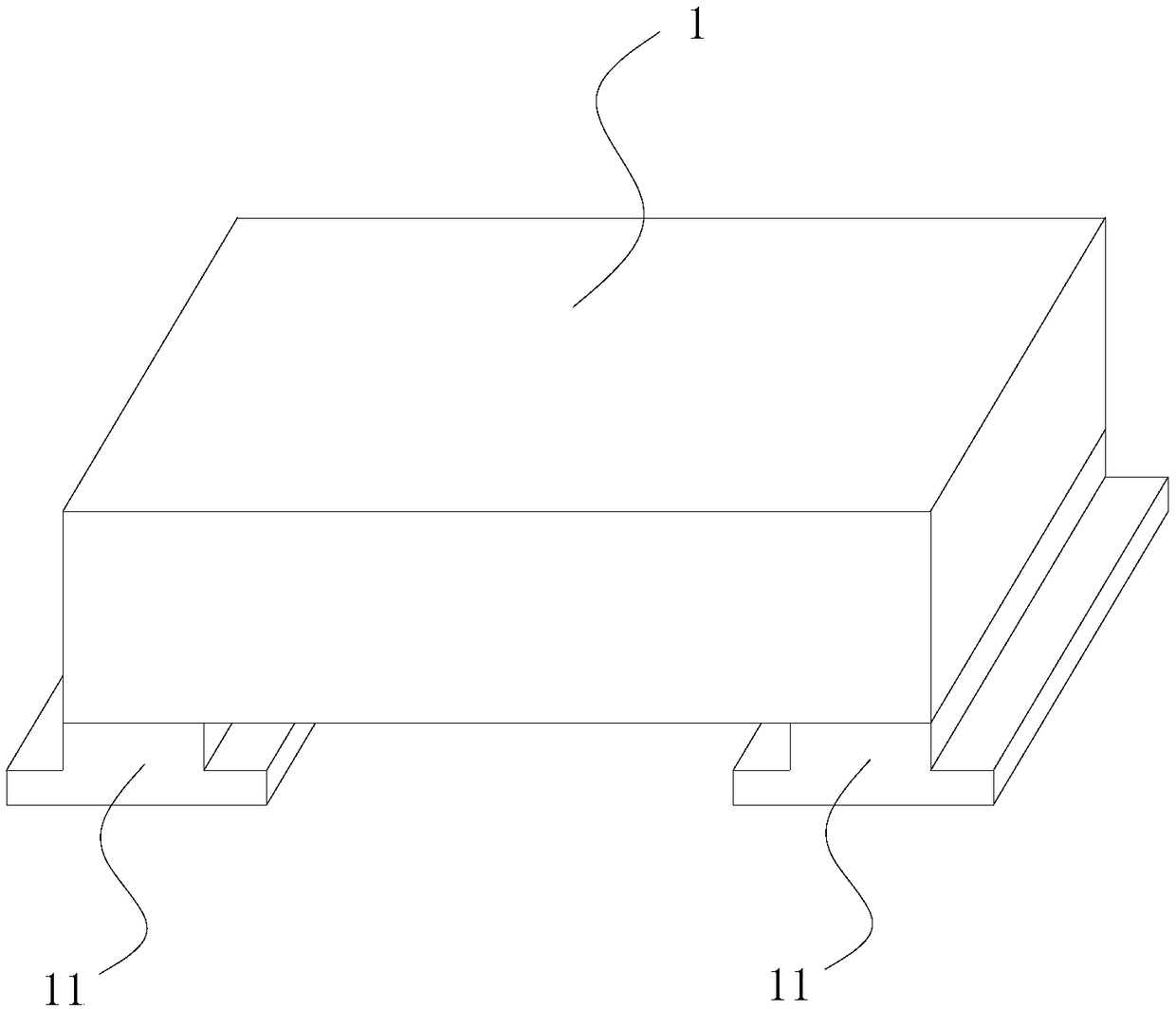

[0029] The preferred embodiment discloses a light bar. Such as figure 2 and image 3 As shown, the light bar includes an LED lamp 1 and a substrate 2, and a plurality of pairs of U-shaped slots 21 are provided on the substrate 2, and the U-shaped slots 21 form openings on one side of the substrate 2; There are a pair of clamping blocks 11, and the pair of clamping blocks 11 on an LED lamp 1 are matched with a pair of U-shaped clamping grooves 21, and the clamping blocks 11 can slide in and out along the U-shaped clamping groove 21 in the plane where the substrate 2 is located (Such as figure 2 As shown by the middle arrow), the U-shaped slot 21 can limit the movement of the LED lamp 1 in a direction perpendicular to the substrate 2 .

[0030] The LED lamp 1 can slide in and out of the U-shaped card slot 21 through the block 11 on it, and be fixed on the substrate 2 through the U-shaped card slot 21. The LED lamp 1 is easy to disassemble, has high disassembly efficiency, a...

Embodiment 2

[0044]This preferred embodiment discloses a backlight module, including the light bar as described in the first preferred embodiment. The LED light on the light bar is easy to disassemble and assemble. When a certain LED light is not on, you can only replace the damaged light without scrapping the entire light bar, which reduces the cost of use and improves the replacement efficiency of the light bar; The installation efficiency of the LED lamp is high, thereby improving the assembly efficiency of the backlight module.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com