Industrial power plug and socket mechanism capable of self locking

A power plug, self-locking technology, applied to circuits, electrical components, parts of connecting devices, etc., can solve the problems of operator personal safety, position error, difficult electrical connection and locking of electrical interfaces, etc., to achieve low manufacturing costs, The effect of preventing accidental touch and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

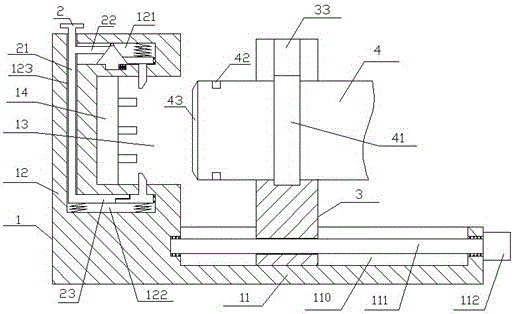

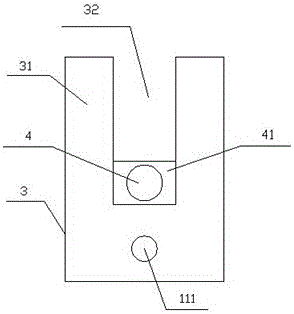

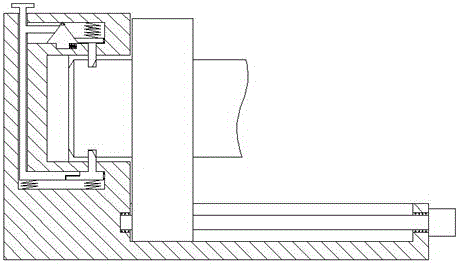

[0020] Such as Figure 1-Figure 5 As shown, an industrial and self-locking power plug and socket mechanism of the present invention includes a socket body 1 and a plug-in drive mechanism 3, and the socket body 1 is fixedly arranged on the right side of the frame 12 by a frame 12. The base 11 at the bottom of the side is composed of a sliding groove 110 inside the base 11. The bottom of the plug-in drive mechanism 3 is embedded in the sliding groove 110 and is connected by sliding fit. The sliding groove 110 is There is a driving screw 111 extending along both sides of the sliding groove 110, the driving screw 111 passes through the plug-in driving mechanism 3 and is threadedly connected, and the right side of the driving screw 111 passes through the base 11 and rotates A drive motor 112 is mated and connected, and the outer wall of the drive motor 112 is fixedly connected to the adjacent side of the base 11. Two sets of brackets 31 are fixed on both sides of the top of the plu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com