Welding strip dual traction mechanism and welding strip traction method

A traction mechanism and dual traction technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as affecting the running speed of the machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with specific drawings.

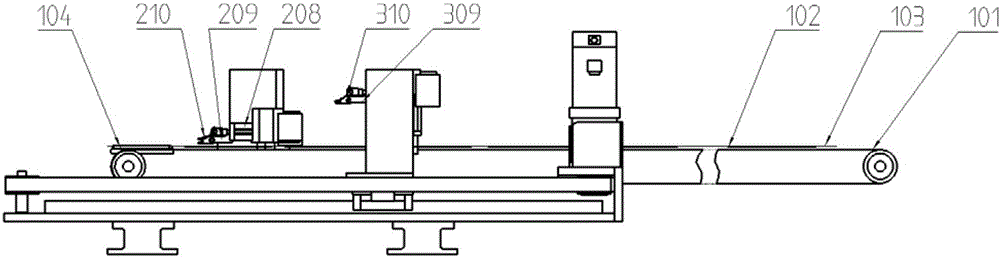

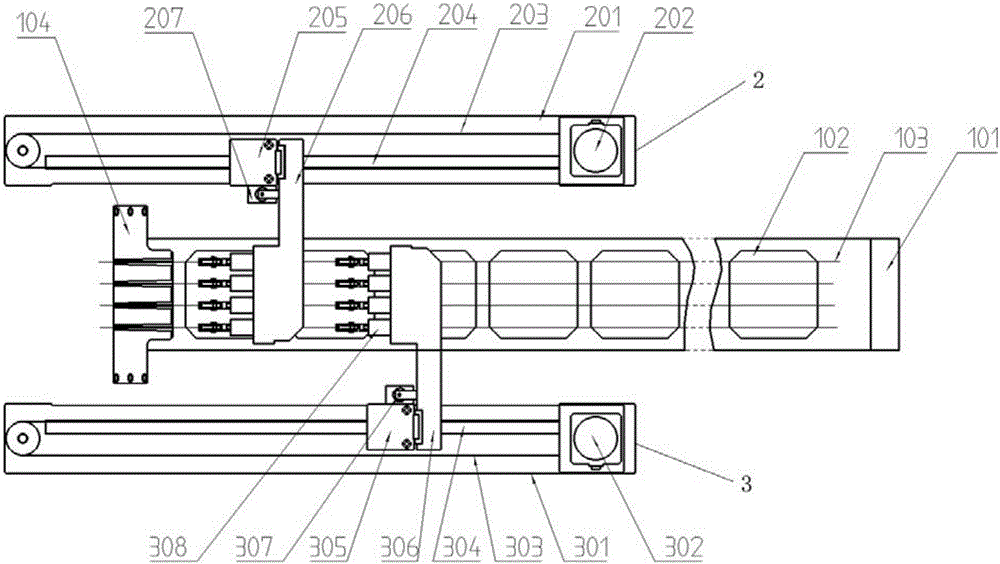

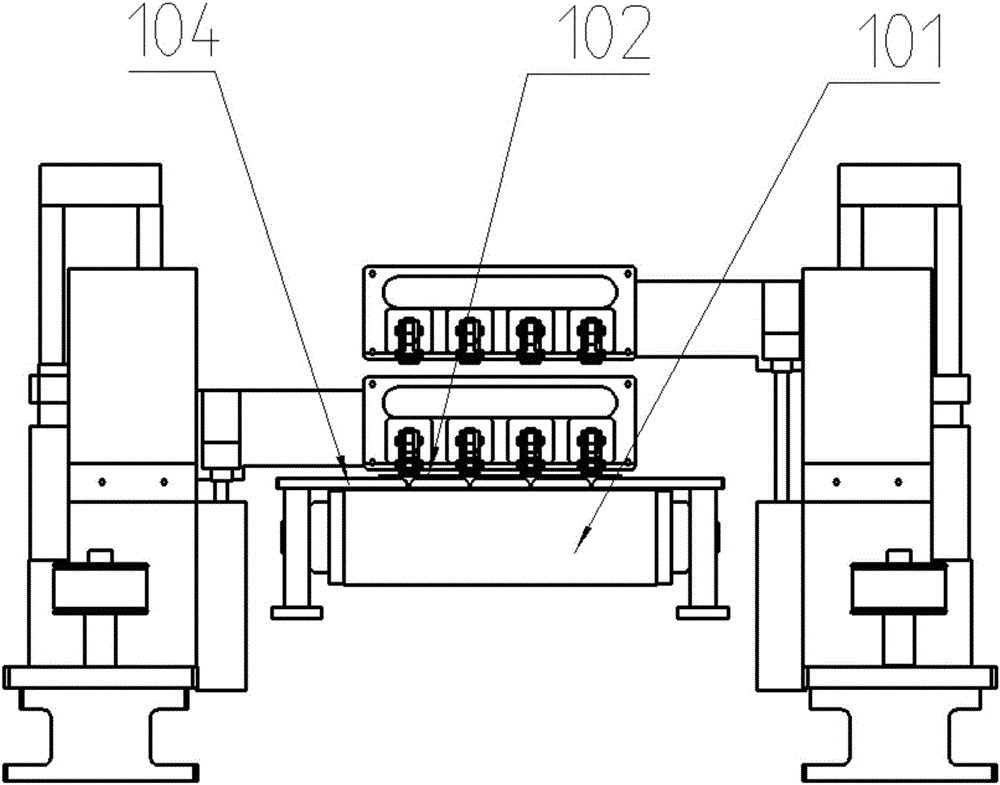

[0030] Such as Figure 1 ~ Figure 3 As shown: the ribbon double traction mechanism includes a first traction mechanism 2, a second traction mechanism 3, a conveyor belt 101, a battery sheet 102, a welding ribbon 103, a guide plate 104, a first bracket 201, a first motor 202, a second A belt 203, a first slide rail 204, a first slide block 205, a first jaw arm 206, a first cylinder 207, a second cylinder 208, a first fixed claw 209, a first movable claw 210, a second support 301, Second motor 302, second belt 303, second slide rail 304, second slide block 305, second jaw arm 306, third cylinder 307, fourth cylinder 308, second fixed claw 309, second movable claw 310 .

[0031] In a specific embodiment, with figure 1 The inward direction of the vertical paper surface is the front, and the outward direction of the vertical paper surface is the back.

[0032] Such as figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com