Sliding core device

A sliding type and core technology, which is applied in the field of sliding core devices, can solve the problems of setting countersunk holes, hindering the smooth movement of sliding cores, fixing core guide parts, etc., and achieving the effect of avoiding interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

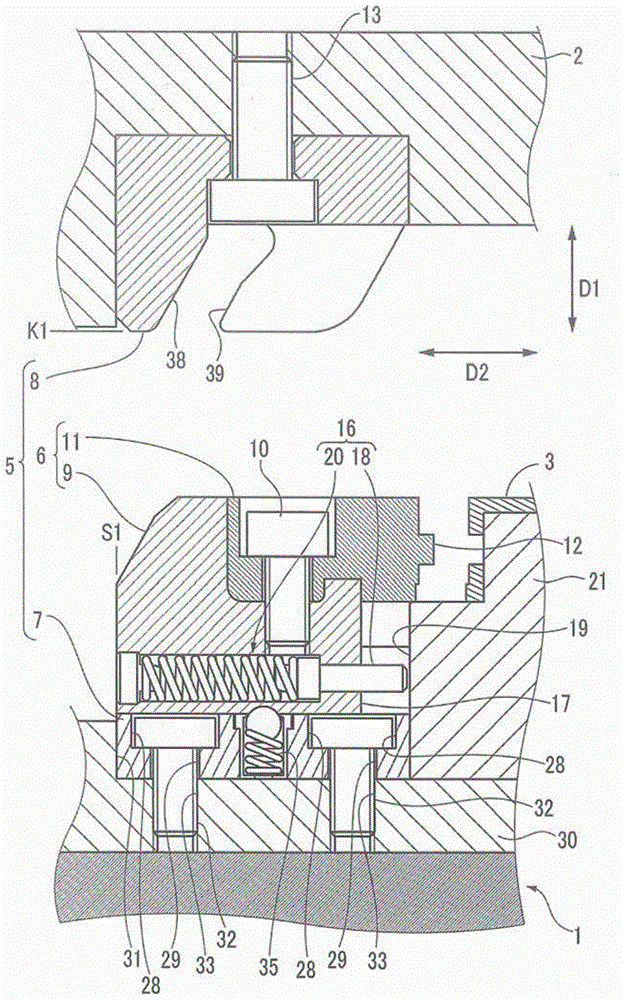

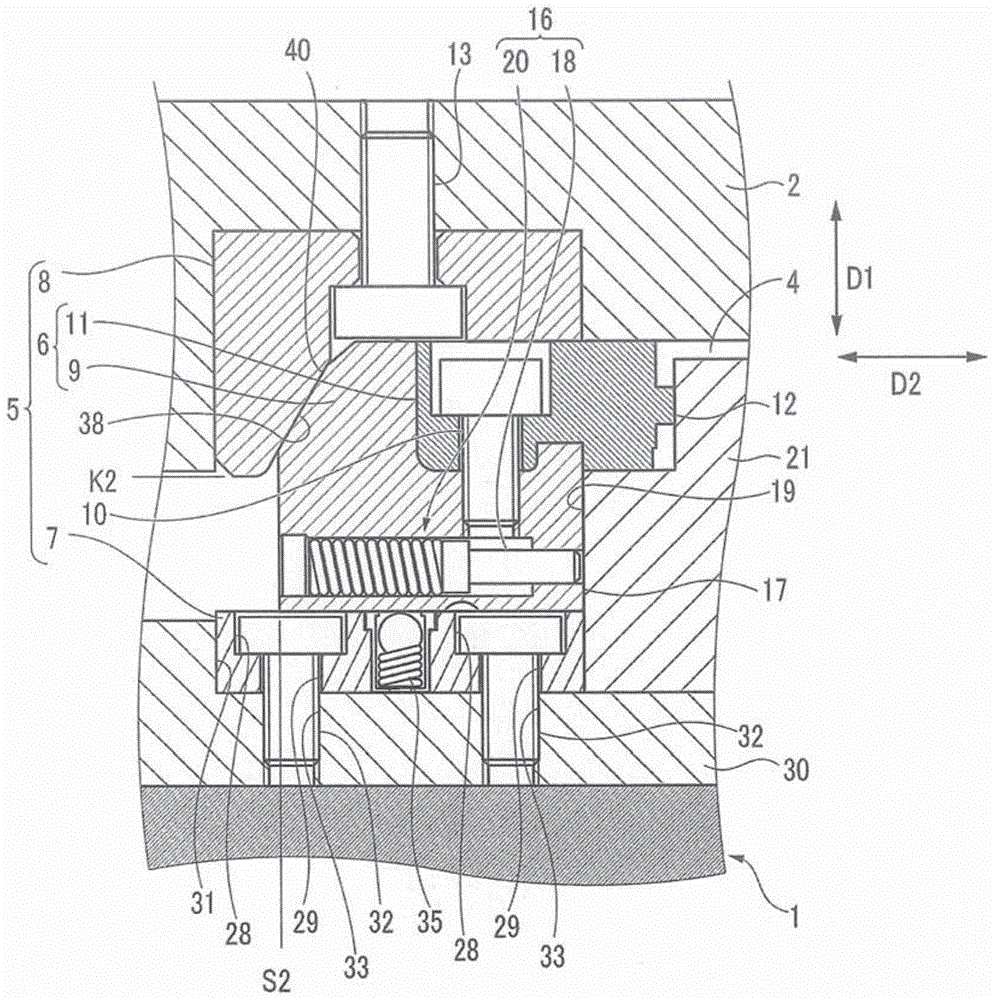

[0072] Hereinafter, embodiments of the present invention will be described with reference to the drawings. figure 1 It is a cross-sectional view of a part of a mold having a sliding core device according to an embodiment of the present invention. like figure 1 As shown, the mold has a first parting mold 1 and a second parting mold 2 which are opened and closed in a first direction D1 , and a sliding core arrangement 5 . Sliding core device 5 forms cavity 4 ( figure 2 ), the cavity 4 is used to form the molded product 3 together with the first split mold 1 and the second split mold 2. Here, by driving the first split mold 1, the first split mold 1 and the second split mold 2 are opened or closed.

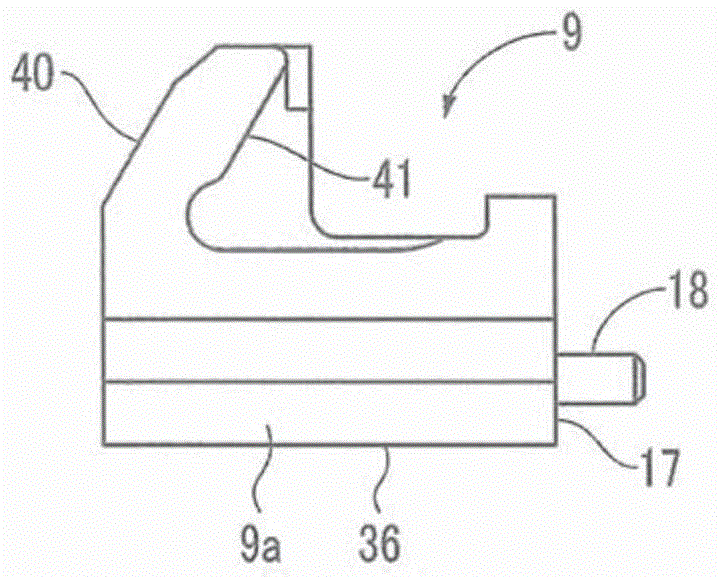

[0073] The slide core device 5 includes a slide core 6 , a core guide 7 , and a cam 8 . The sliding core 6 is moved on the first split mold 1; the core guide 7 can slide the core 6 between the retreat position S1 and the molding position S2 ( figure 2 ) to guide the sliding co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com