Composition for manufacturing vitrimer resins of epoxy/anhydride type comprising polyol

A composition and polyol technology, applied in the field of compositions, can solve the problems of inability to help fabric impregnation and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0167] The preparation of the compositions can be carried out in any type of mixer known to a person skilled in the art. In particular, this can be carried out by bringing into contact the ingredients described for the kit to form the composition according to the invention.

[0168] Shaping can be performed by any technique known to a person skilled in the art in the field of thermosetting resins, in particular by moulding. Notably, the invention makes it possible to also provide other molding modes such as casting, filament winding, continuous molding or molding between film coatings, injection, pultrusion, resin transfer molding or RTM, reaction Injection molding (or RIM) or any other method known to those skilled in the art, as described in: "Epoxy Polymer" edited by J.P.Pascault and R.J.J.Williams, Wiley-VCH, Weinheim 2010 or R.Perrin and "Chimie industrielle" ["Industrial chemistry"] by J.P. Scharff, Dunod, Paris 1999.

[0169] Forming may consist of placing in powder o...

Embodiment 2

[0218] Example 2: Synthesis of epoxy-anhydride network in the presence of 1% TBD and polyol

[0219] Three samples were prepared in the same manner as the sample of Example 1 except that the polyol was added to the reaction mixture and the anhydride was introduced in liquid form. The Tg and storage modulus G' of the materials thus obtained were also measured and summarized in Table 1 below.

[0220] Table 1

[0221] sample 2a 2b 2c Polyol glycerin glycerin TMP* mol% OH / 环氧

10 20 10 Tg(°C) 146 144 144 G'(MPa) 15 15 16.7

[0222] *Trimethylolpropane

[0223] Note that these polyols make it possible to slightly increase the storage modulus of the materials, which reflects their crosslink density, without substantially affecting their Tg. This suggests that the polyol has been incorporated into the polymer network and does not act like a plasticizer, contrary to what would have been expected.

Embodiment 4

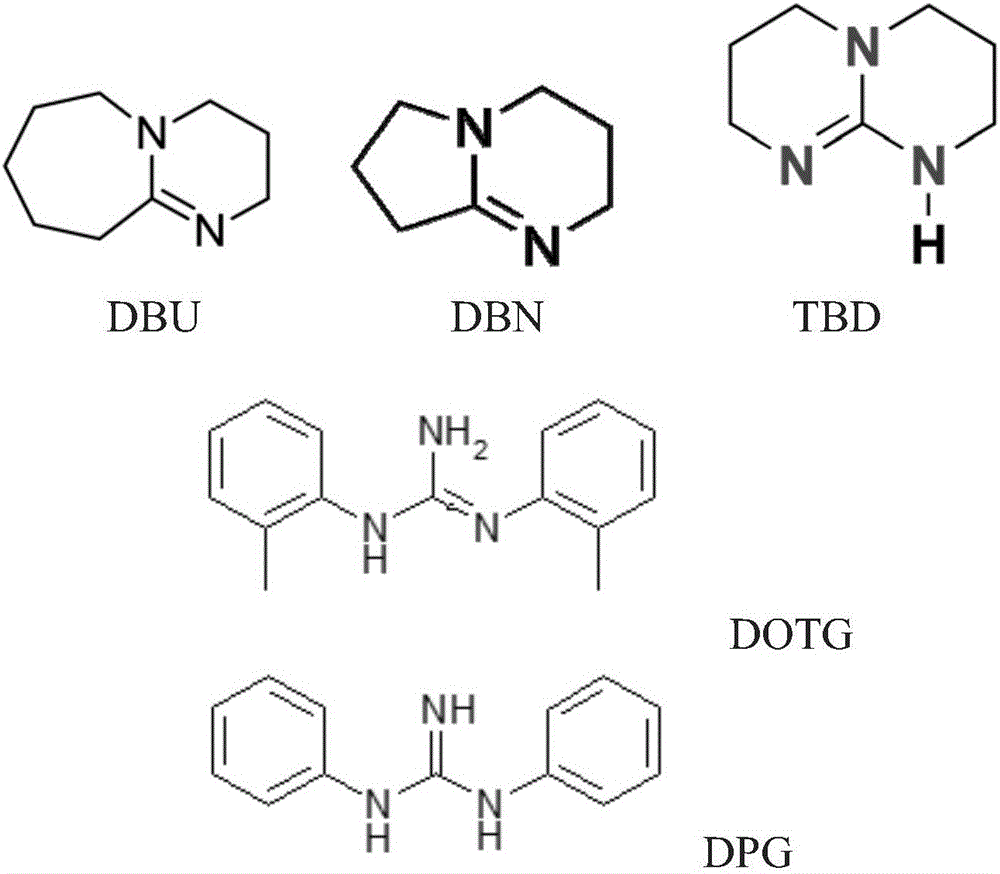

[0226] Example 4: Synthesis of epoxy-anhydride network in the presence of 1% DBU and polyol

[0227] Sample (4) was prepared in the same manner as the sample of Example 3, except that polyol (TMP) was added to the reaction mixture in liquid form. The material exhibited a Tg of 132°C and a storage modulus of 12.4 MPa at 200°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| storage modulus | aaaaa | aaaaa |

| storage modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com