Leakage-free rapid disconnect connector

A kind of disconnector and fast technology, applied in the direction of coupling, mechanical equipment, etc., can solve the problems of medium leakage of the disconnector, poor sealing performance of the disconnector, inability to guarantee the safety of hazardous media, etc., to ensure safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

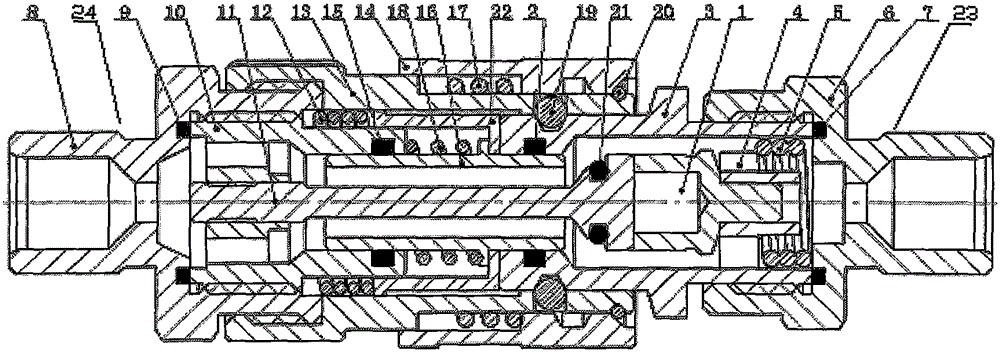

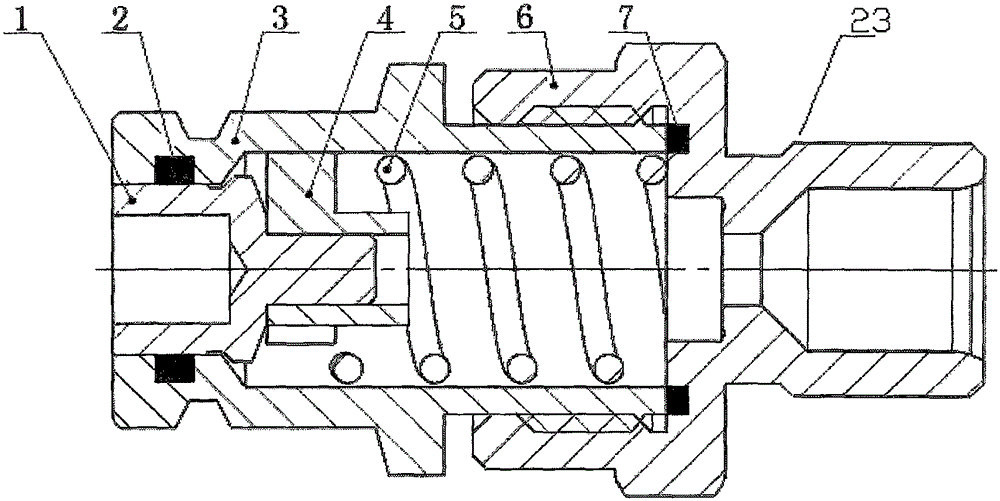

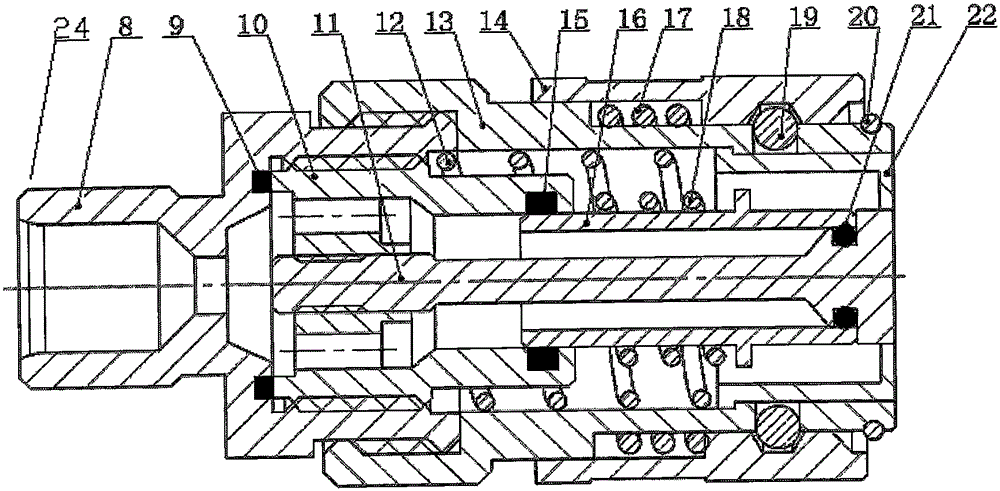

[0018] Example: such as Figure 1-3 As shown, a non-leakage quick disconnect of the present invention includes a cathode connector 23 and an anode connector 24 arranged at one end of the cathode connector 23, the cathode connector 23 is provided with a plug 1, and the plug 1 passes through the first sealing ring 2 Connect the insertion frame 3, the insertion frame 3 has a built-in spring seat 4 and one end of the spring seat 4 is connected to the cathode spring 5, the insertion frame 3 is threaded to the cathode tube joint 6, and the insertion frame 3 is connected to the cathode tube joint 6 There is a second closed ring 7 between them, the cathode tube joint 6 is connected to the anode tube joint 8 at one end of the anode joint 24, the inner side of the anode tube joint 8 is spirally connected to the inner skeleton 10 and the inner skeleton 10 is connected to the anode tube joint 8 is provided with a third sealing ring 9, the outside of the anode pipe joint 8 is spirally conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com