A cage stopper

A technology of vehicle arrester and cage, which is applied to lifting equipment, transportation and packaging in mines. It can solve the problems of vehicles jumping out of the cage, materials or equipment slipping, and jumping out of the cage, so as to achieve the effect of improving safety and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

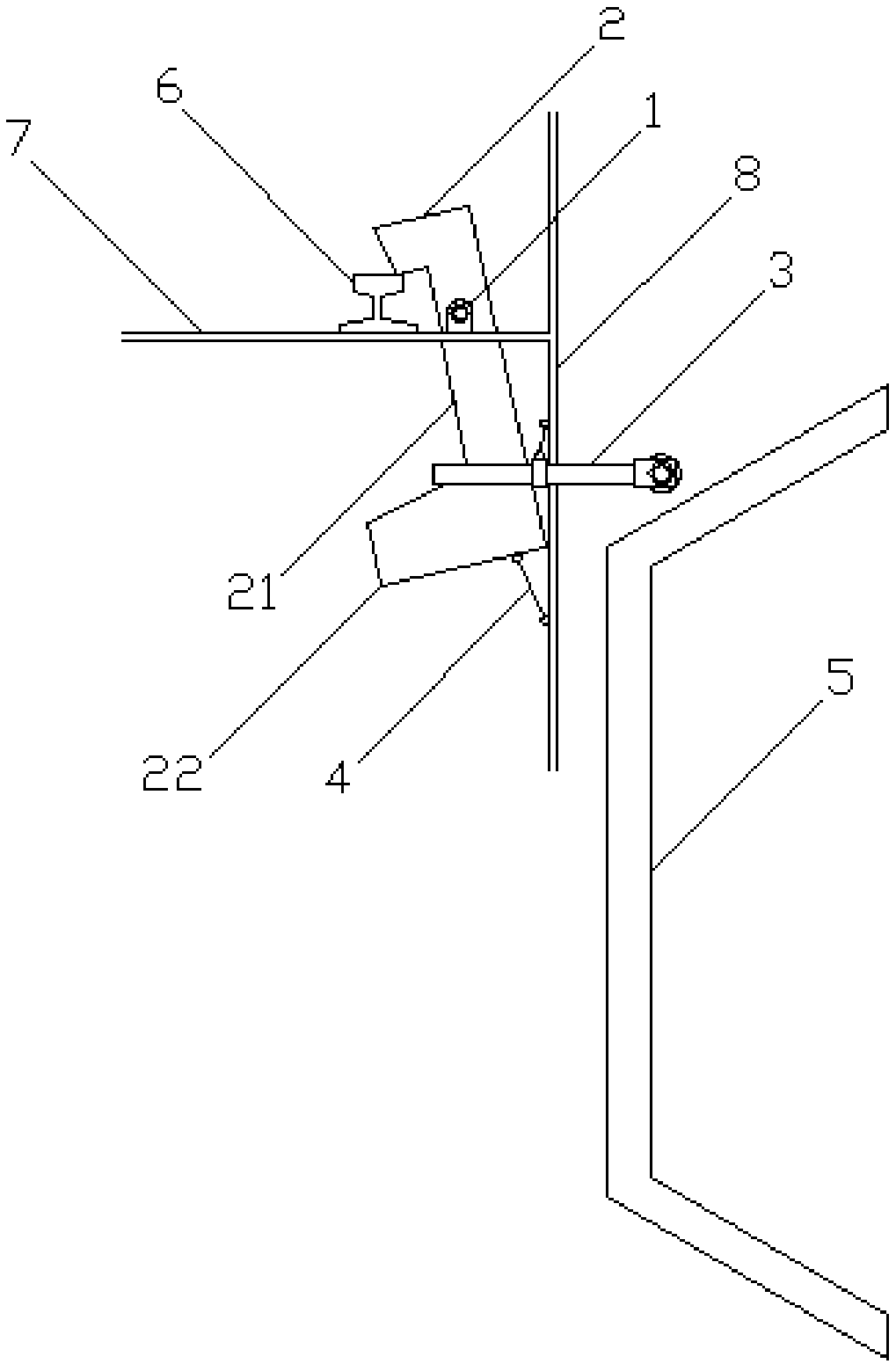

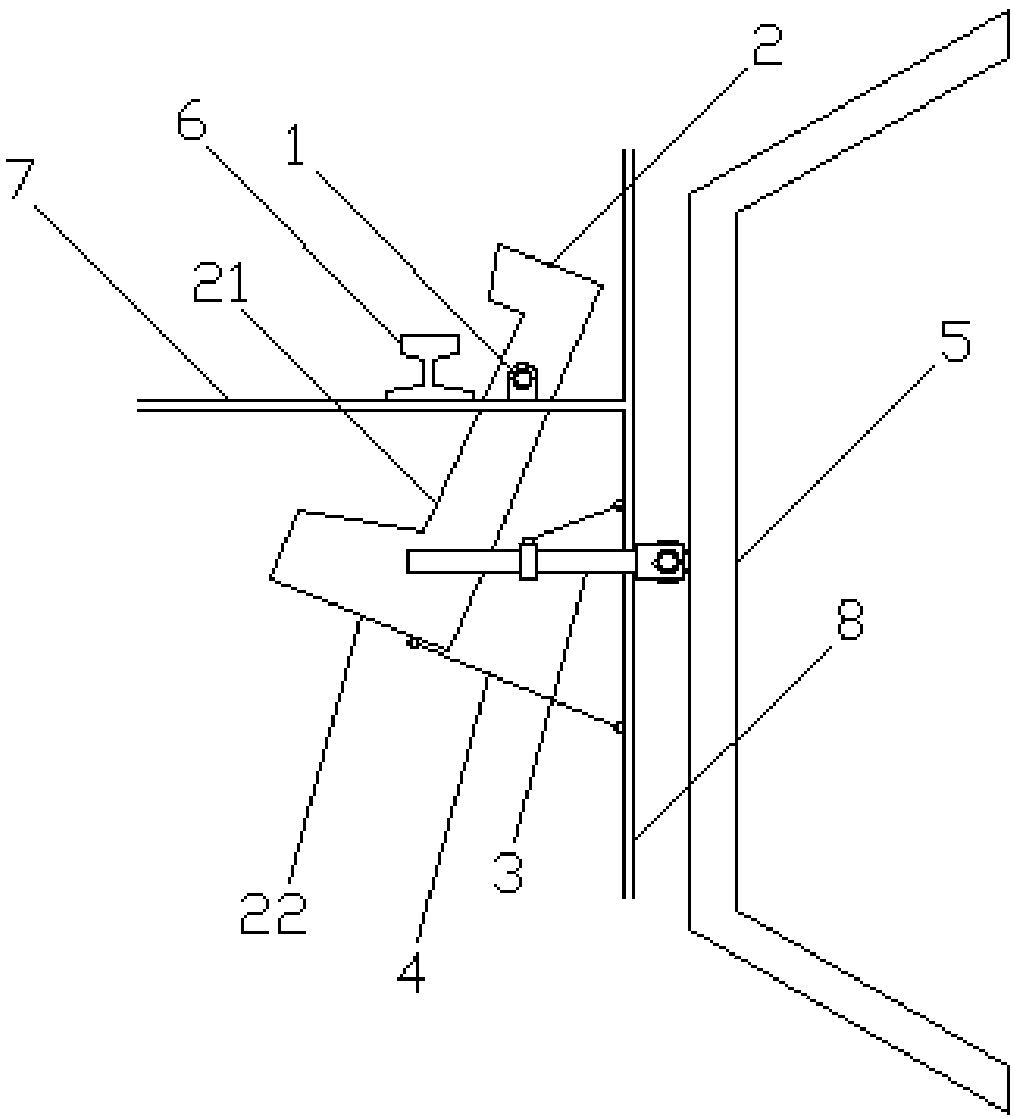

[0029] Such as Figure 1-5 As shown, a cage car arrester includes a base 1 , a baffle 2 , a control rod 3 , an elastic mechanism 4 and a guide rail 5 .

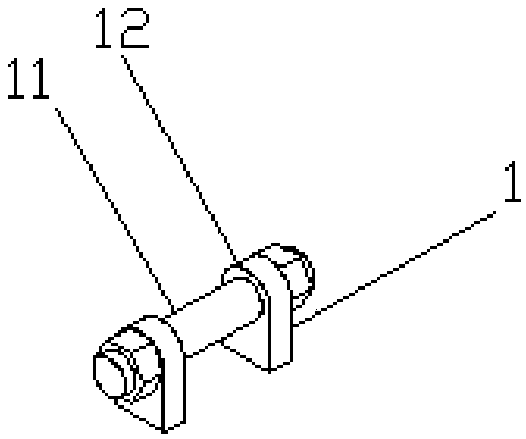

[0030] The base 1 includes a seat shaft 11 and a support plate 12, the seat shaft 11 adopts M16×92mm bolts, and the support plate 12 adopts a 10mm thick steel plate.

[0031] Two support plates 12 are arranged oppositely, and are welded on the top of the cage bottom plate 7 and the outside of the cage rail 6 .

[0032] The seat shaft 11 passes through the holes on the two support plates 12 and is connected between the two support plates 12 , and is fixed by two nuts respectively located outside the two support plates 12 , and a washer is arranged between the nuts and the support plates 12 .

[0033] The seat shaft 11 is parallel to the direction of the cage rail 6, the distance between the central axis of the seat shaft 11 and the cage bottom plate 7 is 25 mm, and the distance from the side plate 8 is 110 mm, and the side pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com