Automobile torsion beam back bridge fatigue test device

A kind of fatigue test and torsion beam technology, applied in the direction of vehicle suspension/shock absorber testing, etc., can solve the problems of experimental error, failure to detect fatigue cracking of rear axle in time, and high cost, so as to avoid human judgment errors and shorten fatigue experiments. The effect of simple cycle and device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

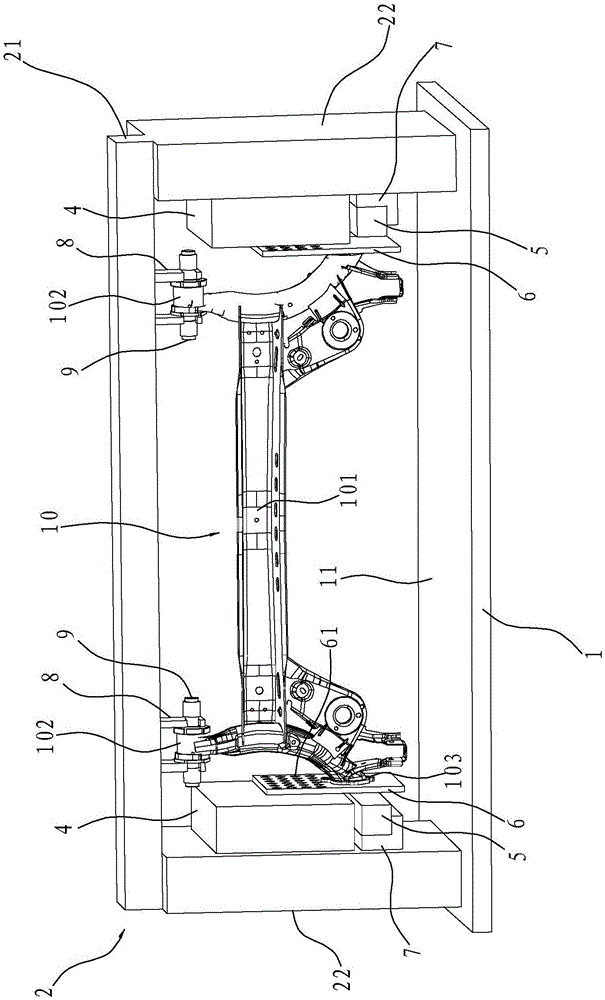

[0014] like figure 1 Shown, a kind of automobile torsion beam type rear axle fatigue test device, comprises workbench 1, and the table top 11 of this workbench 1 is provided with stand 2, and this stand 2 is door shape, comprises the beam 21 on the top and is arranged on The vertical beams 22 on both sides of the cross beam 21 . The torsion beam rear axle 10 of the automobile to be tested is hinged on the stand 2. Specifically, two hinged supports 8 are arranged on the crossbeam 21, and a rotating shaft is respectively pierced on each bush sleeve 102 of the torsion beam rear axle 10. 9, and the two ends of the rotating shaft 9 are respectively connected with the two ends of the hinged support 8, so that the bush sleeve 102 forms a hinge with the stand 2, and at the same time the torsion beam 101 of the torsion beam rear axle 10 of the automob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com